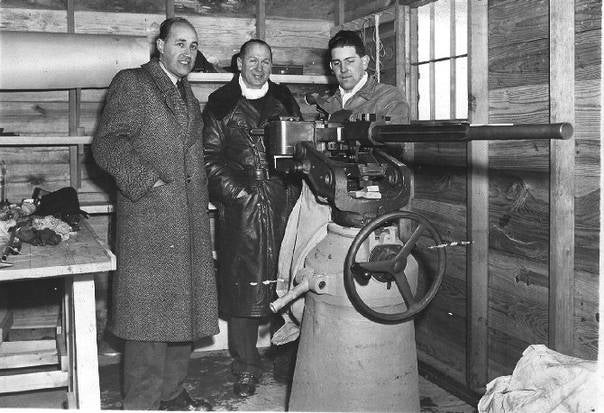

The Providence Journal has a fascinating article about the many layers of subcontracting that took place during WWII. Richard Parker writes about his time as a driver for the Pantex Pressing Machine Company. During the war the company was sub-contracted to make clones of the famous Oerlikon 20mm cannon and other weapons. Once a week Mr Parker would drive an incomplete torpedo across town to the home of an elderly machinist …

To deliver it, I then drove to a working-class section of Pawtucket. Arriving at my destination, instead of formidable gates of a giant defense plant, I’d ring the bell of a three-decker wooden tenement and be greeted by an elderly man with a strong British accent. After chatting a bit we’d lift the warhead off the truck, roll it across the courtyard to the cellar door and, an old man and young one, carefully slide it down the stairs and roll it across the floor to his lathe.

Machinists usually love their work. Like many, this retired machinist had a well-equipped workshop to do precise and difficult grinding operations. At the lathe we’d lift off the warhead previously worked on, boost up the new one, lock it in place, roll the completed one across the floor, up the stairs, across the courtyard and hoist it onto my truck. And that’s how subcontracting won the war.

One of the most famous guns to be outsourced was the M1911 pistol. It was made by a typewriter manufacturer (Remington Rand), a sewing machine maker (Singer) and a railway signaling equipment manufacturer (Union Switch & Signal).

Many thanks to Earl for the tip.

Your Privacy Choices

Your Privacy Choices