Welcome back to Wheelgun Wednesday, our weekly article series where we cover everything related to revolvers. Today’s topic is the technical challenge of effective sound suppression of revolvers. In Part 1 we looked at mechanically sealed revolvers, today we’ll focus on “Gap Sealing Cartridges”, an uncommon approach with plenty of potential.

Wheelgun Wednesday @ TFB:

- Wheelgun Wednesday: Silencing the Gap – Part 1

- Wheelgun Wednesday: Smith & Wesson Texas Rangers Bicentennial Revolver

- Wheelgun Wednesday: Penn Arms GL65-40 Launcher

- Wheelgun Wednesday: Double Revolver from San Marino

- Wheelgun Wednesday: Super Redhawk 22 Hornet! Who Approved This?!?

Wheelgun Wednesday: Silencing the Gap – Part 2

Concept

In Part 1 we’ve seen that the most common sealed revolver, the M1895 Nagant, combines a mechanical action with a peculiar cartridge to seal its cylinder gap. The two solutions must work together to provide the seal: the cartridge alone would not offer any advantage in a conventionally designed revolver. Now we’ll look at cartridges designed to offer a sealing function, with no changes required on the standard revolver architecture.

In these cartridges, the bullet is generally seated deeper within the case and upon firing the sealing element moves from the case towards the barrel, providing a reliable obturation of the gap and preventing the release of gas. This configuration places this type of cartridge in the “telescoped ammunition” category.

Known Use

As far as we can tell there has been only a couple of actual firearms utilizing the concept of telescoped ammunition to provide effective suppression to a revolver. These are the Knight’s Armament Company Revolver Rifle and Revolver Pistol.

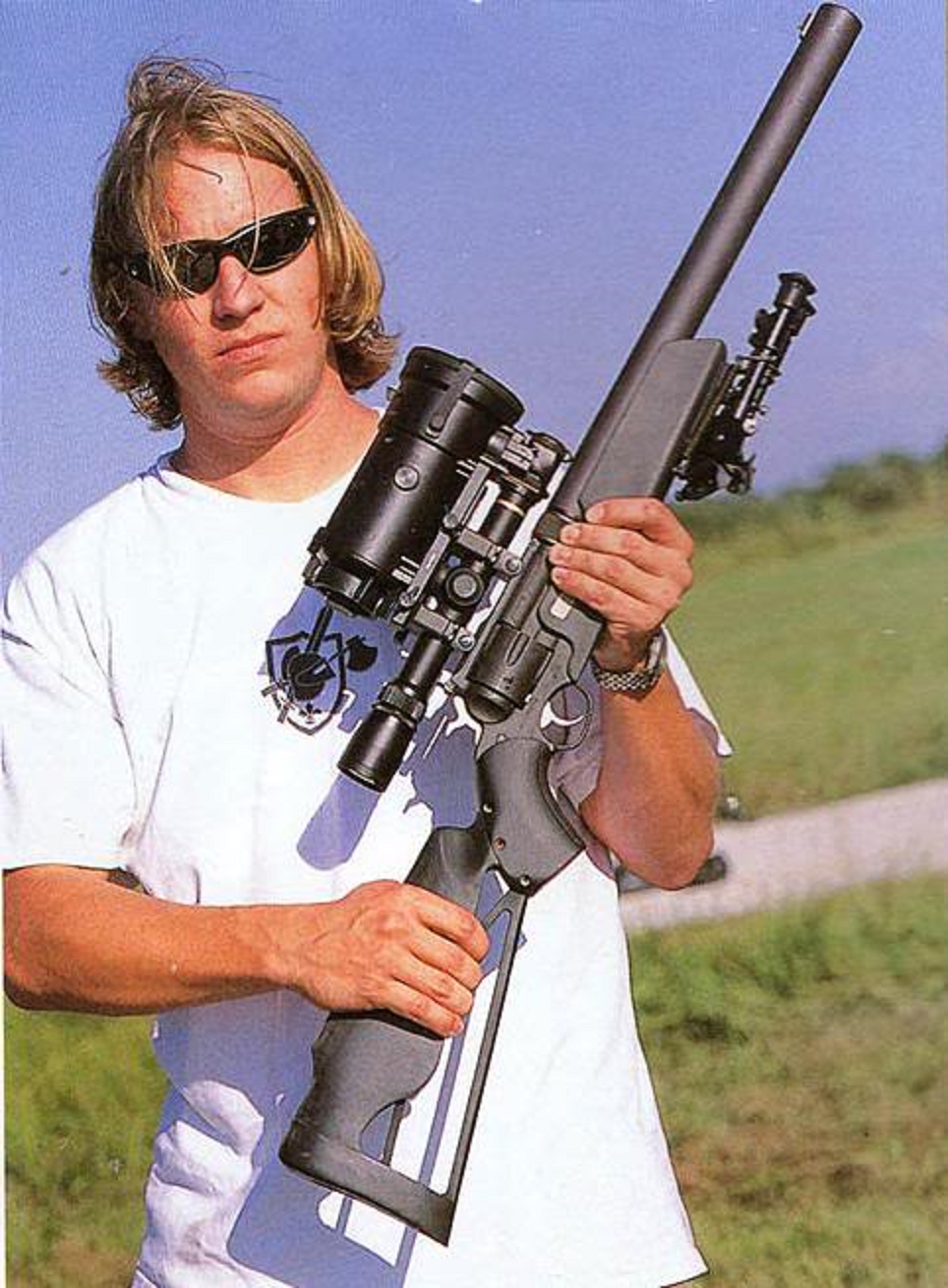

The first, possibly a little more known thanks to a few photos floating on the internet, is an integrally suppressed rifle built on a modified Ruger Super Redhawk .44 Magnum Revolver.

Wheelgun Wednesday: Silencing the Gap – Part 2 – KAC Suppressed Revolver Rifle based on a .44 Magnum Ruger Super Redhawk (Image credit: Mythic Armory)

The pistol version is built on a modified Ruger GP100.

Wheelgun Wednesday: Silencing the Gap – Part 2 – KAC Suppressed Revolver Rifle and Revolver Pistol (Image credit: Mythic Armory)

The elusive firearms both employ telescoped ammunition, where a full-caliber sabot, presumably in aluminum, holds a sub-caliber bullet (.30 in the .44 rifle, .224 in the .357 pistol). The barrel is bored for the projectile, so upon firing the sabot doesn’t fully leave the cylinder and stops its forward movement against the edge of the barrel, sealing the gap and allowing reliable suppression.

Data about these firearms, allegedly employed during the first Gulf War, is quite limited, but some sources list an energy comparable to a 9mm Luger for the RR and in .22LR level for the RP. Both rounds are subsonic to get the most out of the suppressed setup.

Similar Cartridges

When we talk about telescoped ammunition, a concept quite evolved in automatic cannons, we may think about Textron’s submission to the NGSW program and the previous LSAT. This “Cased Telescoped Ammunition” (CTA) was supposed to operate in firearms with a movable chamber, relative to the barrel, i.e. a solution potentially resulting in high-pressure gas leaking from a chamber-to-barrel gap.

Wheelgun Wednesday: Silencing the Gap – Part 2 – Side view of the Textron 6.8mm CT rounds in a polymer belt (Image credit: Matthew Moss/TFB)

Wheelgun Wednesday: Silencing the Gap – Part 2 – Top view of the Textron 6.8mm CT rounds in a polymer belt (Image credit: Matthew Moss/TFB)

TFB did quite an extensive coverage of the LSAT program (thank you Nathaniel!) and the issue of the gap was discussed in Part 2 of Mrs. Kori Phillips, Program Officer for LSAT, interview (read the whole articles, they are worth the time):

TFB: You obviously have to have a separate chamber and a separate barrel unit. One thing that might be a negative is that on a revolver you have a gap there, where gas can escape. Do you have that problem, or have you found a solution to that?

KP: For case telescoped, the front of the cartridge actually seals the breech, and the plastic flows into the empty space. It’s sort of a balancing act to let the cartridge expand and flow, but not so much that you can’t get the case out of there. It obturates the chamber just like it would with a brass case.

In this case, it appears that careful design and the right selection of materials allow the case to deform just enough to provide a suitable seal. Possibly not the most cost-effective solution for civilian revolvers, as it relies on R&D and unconventional materials, but conceptually an approach that could work.

Patents out there

When the Textron CTA got TFB coverage, several commenters (including yours truly), quickly saw the potential for revolvers chambered in similar cartridges. Couple a rifle round with something like a S&W X-frame and you could get rifle ballistics out of a wheelgun.

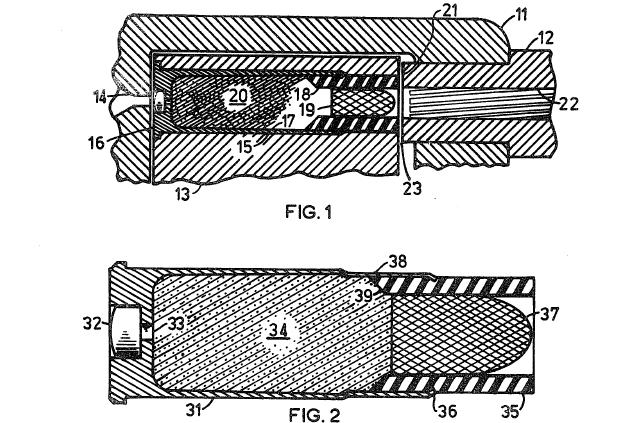

Like the majority of the great ideas that we come up with every day in the comment section, the concept had already seen some development. As the incredibly knowledgeable Daniel E. Watters promptly pointed out, in the ’80s an inventor named Charles R. Olsen devised:

a means for utilizing smaller-diameter bullets in larger-diameter cartridge cases, to achieve higher velocity without bottlenecking the cartridge case, and a firearm having a reduced bore adapted to that cartridge. Additionally, the invention provides a means of sealing the cylinder-to-barrel gap in revolvers, eliminating gas leakage at that point and thereby increasing muzzle velocity by eight to twenty percent.This invention is applicable to current gun models and cartridge components with little modification.

Wheelgun Wednesday: Silencing the Gap – Part 2 – An embodiment of the gas seal round from Patent US 4,457,093 B2 (United States Patent and Trademark Office)

Olsen’s main goal is offering rifle ballistics from a conventionally manufactured revolver, with a line of prototype cartridges he names “INVICTA”. However, he does recognize the suppression potential. The now-expired patent is an easy and interesting read with a plethora of practical insights, uncommon features for this type of document. For example, we know that a material deemed ideal for the sabot is Lexan, a common polycarbonate.

We can see that conceptually the approach is very similar to what KAC employed in the Revolver Rifle and Pistol, and given that at the time Olsen’s patent was active, we can conjecture that he may have had a role in that development.

Interestingly, Olsen’s invention was cited by S&W in a now-abandoned patent filed in 2005. The gap-sealing feature however is completely lost in this invention, and the purpose isn’t as clear.

What If?

As a thought exercise, if we were to replicate Olsen’s concept, or a CTA, in the most accessible way, how would we proceed? Let’s set the goal as replicating the suppressed performance of subsonic .300 BLK, in a revolver.

Let’s see a possible “What If?” scenario.

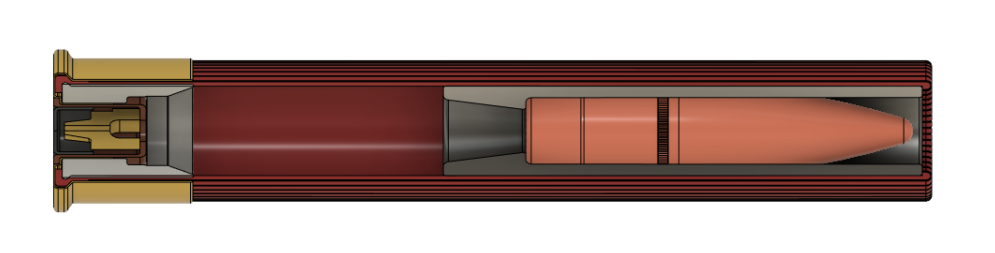

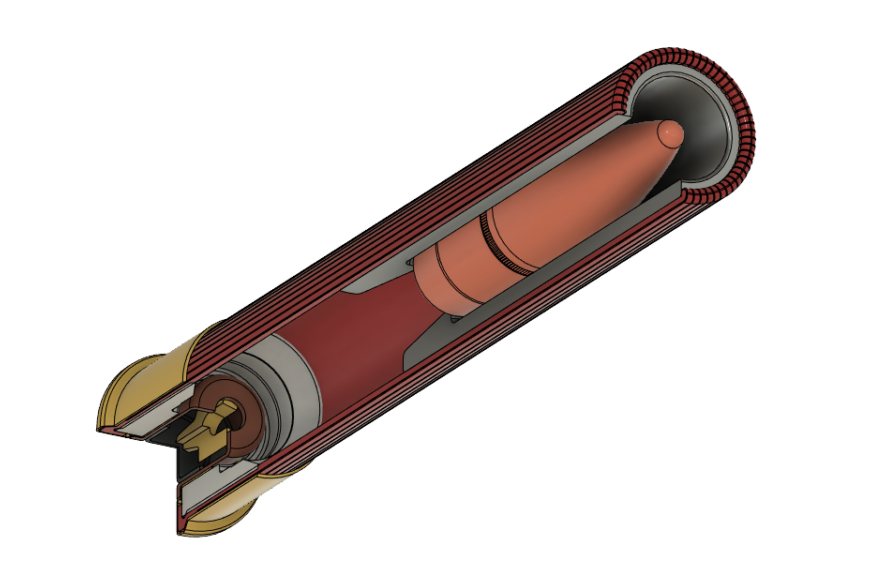

First of all: what is a CTA cartridge if not a glorified shotshell with a sub-caliber slug and barrel? So, let’s select the .410 bore as the cartridge case, the only shotshell with revolvers chambered for. If the revolver can chamber the 3″ version of the shell, we’re sure we can comfortably chamber the heaviest, 200 gr and above, .30 caliber bullets. We’d then need a suitable sabot, capable of providing a seal when pushed against the barrel, without disintegrating. Olsen’s polycarbonate may be a solution, but 3D-printed nylon could be a great candidate.

So here we have it, the concept of the .30-410 TFB.

Wheelgun Wednesday: Silencing the Gap – Part 2 – The .30-410 TFB concept (Shell by Bartosz Rakowski and bullet by V.MAX via GrabCAD)

Wheelgun Wednesday: Silencing the Gap – Part 2 – The .30-410 TFB concept (Shell by Bartosz Rakowski and bullet by V.MAX via GrabCAD)

With .300 BLK as a benchmark, we should have a .30 barrel, hopefully with the right rifling. Enters the Magnum Research BFR with its wide range of customizations. The massive revolver, in its long cylinder configuration, can be chambered in .410 3″ (with plenty of strength to handle several times its design pressure, just in case) but also in .300 BLK, meaning that the two main components are readily available.

Wheelgun Wednesday: Silencing the Gap – Part 2 – Magnum Research BFR in .30-410 TFB with a Dead Air Nomad 30 suppressor

Granted, Magnum Research surely strives to always associate the caliber of the barrel to the one of the cylinder, but given the extent of unconventional projects their custom shop handles (including threaded barrels), the possibility truly seems there.

Conclusions

What do you readers think about having the cartridge itself carry the effort of sealing the cylinder gap? Would you agree that a commercial solution based on Olsen’s patent would be very interesting? Do you like the .30-410 TFB or do you have better options?

As usual, let us know in the comments. (And feel free to tease Magnum Research’s custom shop with this concept, who knows…)

Your Privacy Choices

Your Privacy Choices