Additive Manufacturing, more commonly known as 3D Printing, is becoming increasingly mainstream in the production of firearms components and accessories. We’ve already seen commercial attempts at manufacturing polymer 3D-printed suppressors and now, thanks to Forerunner 3D Printing, we can see how 3D-printed nylon survives a couple of hundreds of rimfire rounds.

More 3D Printed Silencers @ TFB:

- New 3D Printed Titanium Suppressor: The HUXWRX Flow762 [GunCon 2023]

- SILENCER SATURDAY #281: Let It Flow Through You – HUXWRX FLOW 762 Ti

- SIG Sauer MODX-45 Modular 3D Printed Suppressor Available Now

- Introducing The Mute Polymer 3D Printed Suppressor

Destructive Testing of a 3D-Printed Nylon Suppressor (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor

The technology: HP Multi Jet Fusion (MJF)

Let’s make it clear from the beginning: the 3D printer employed by Forerunner 3D Printing (FR3D) for the lawful manufacturing of silencer components isn’t one of the commonly available desktop units adopting a filament feedstock. The HP MJF printers are industrial manufacturing equipment using a powdered polymer (generally a close relative to Nylon) and capable of producing hundreds of parts per build.

This technology, similar to Selective Laser Sintering, is getting increasingly adopted by different industries and we’ve seen it already a few times in the firearm world. Recent examples are aftermarket H&K furniture and NODs housings.

The suppressor

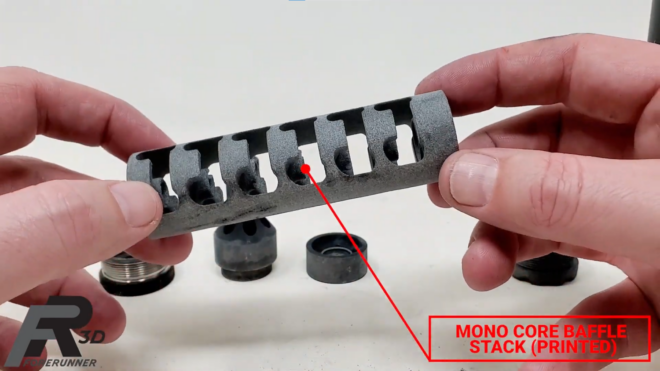

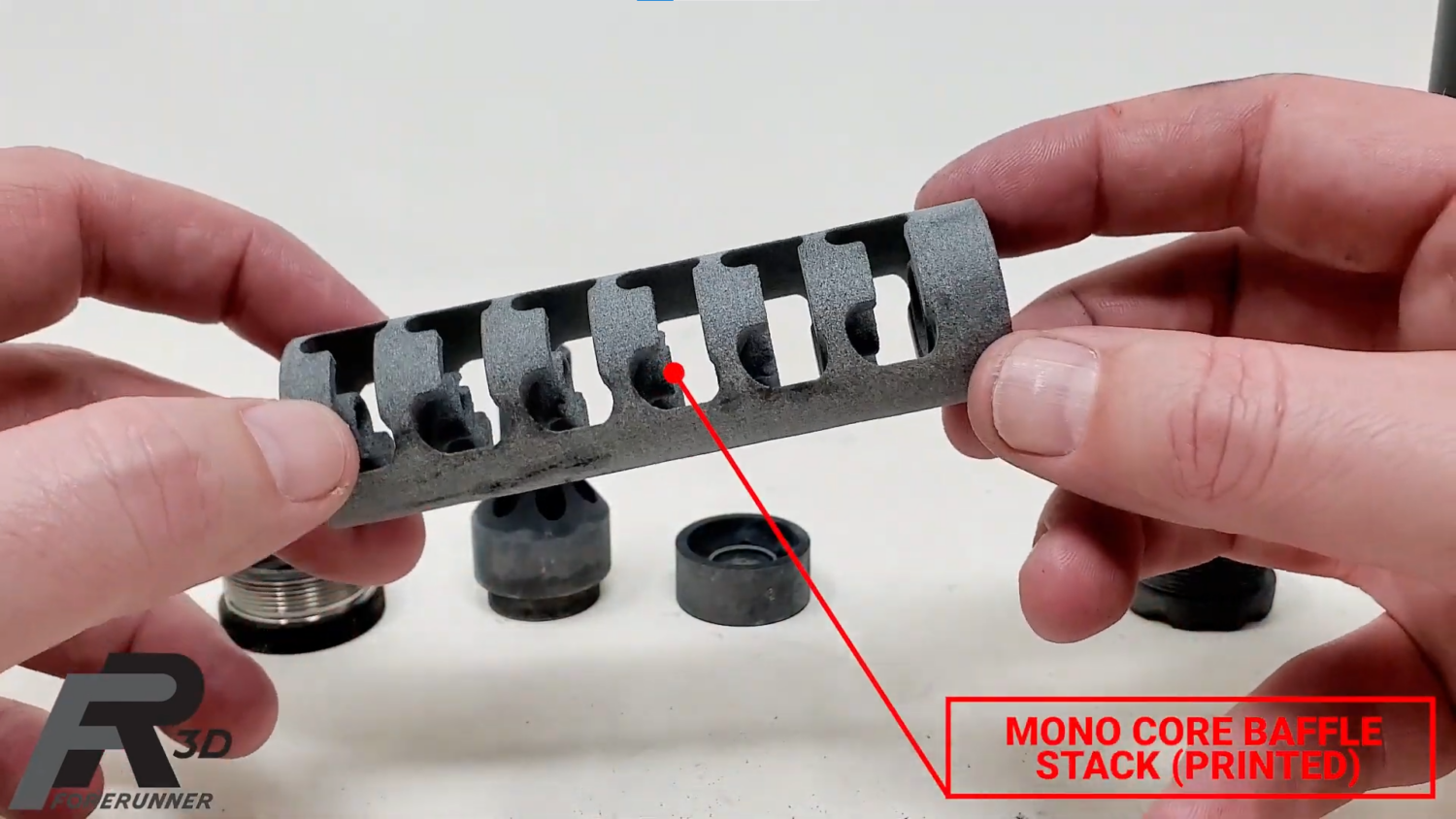

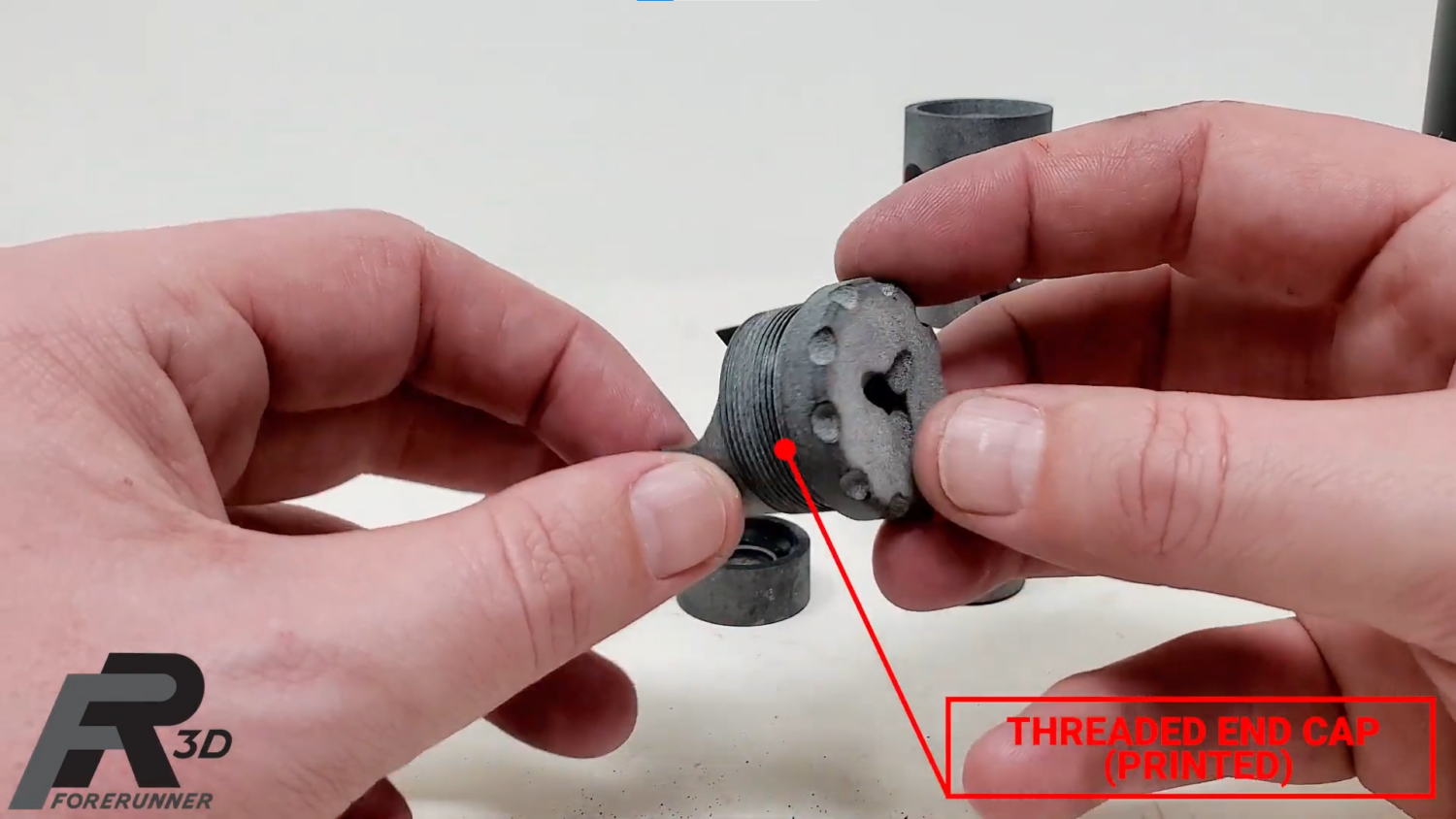

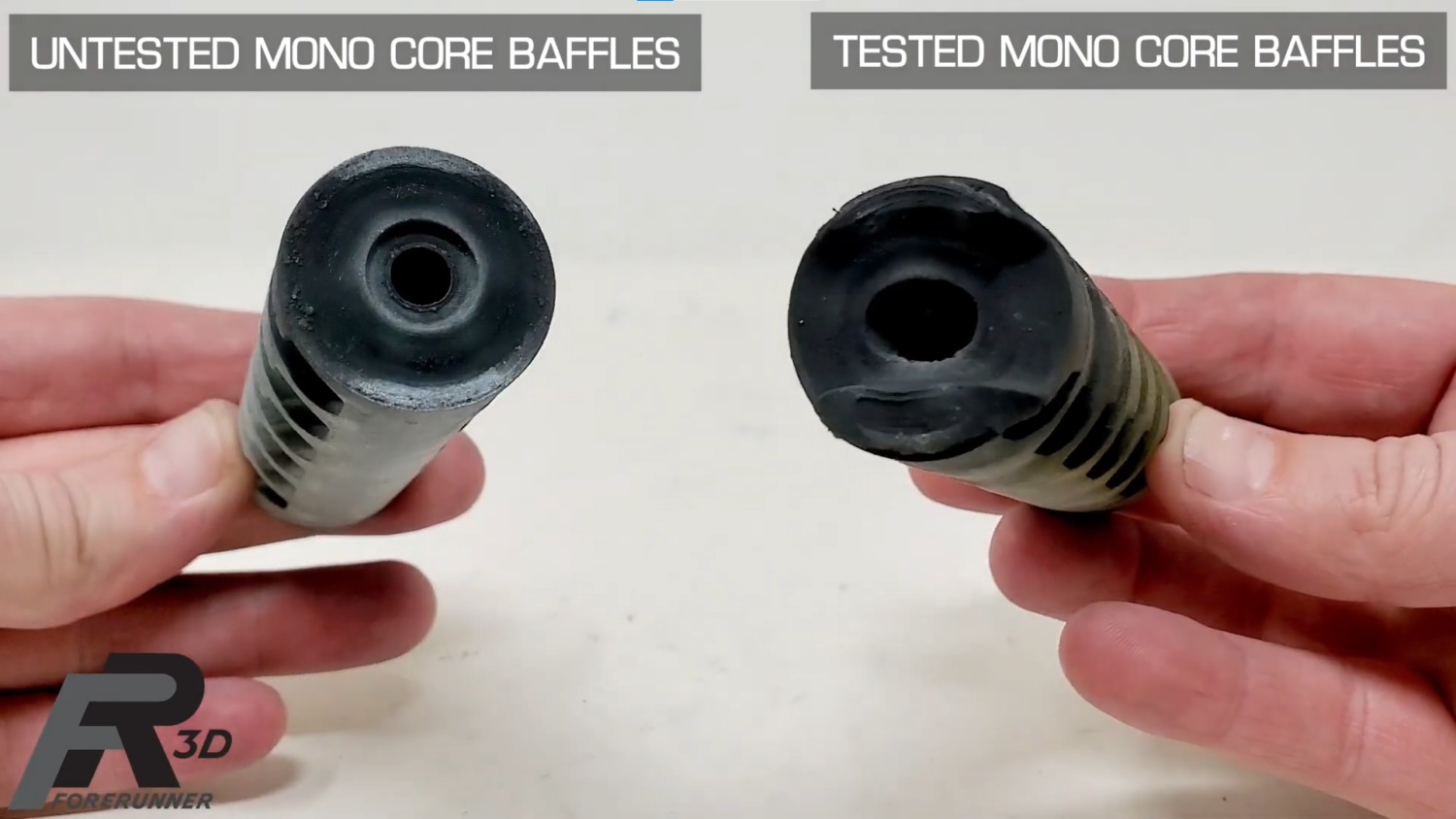

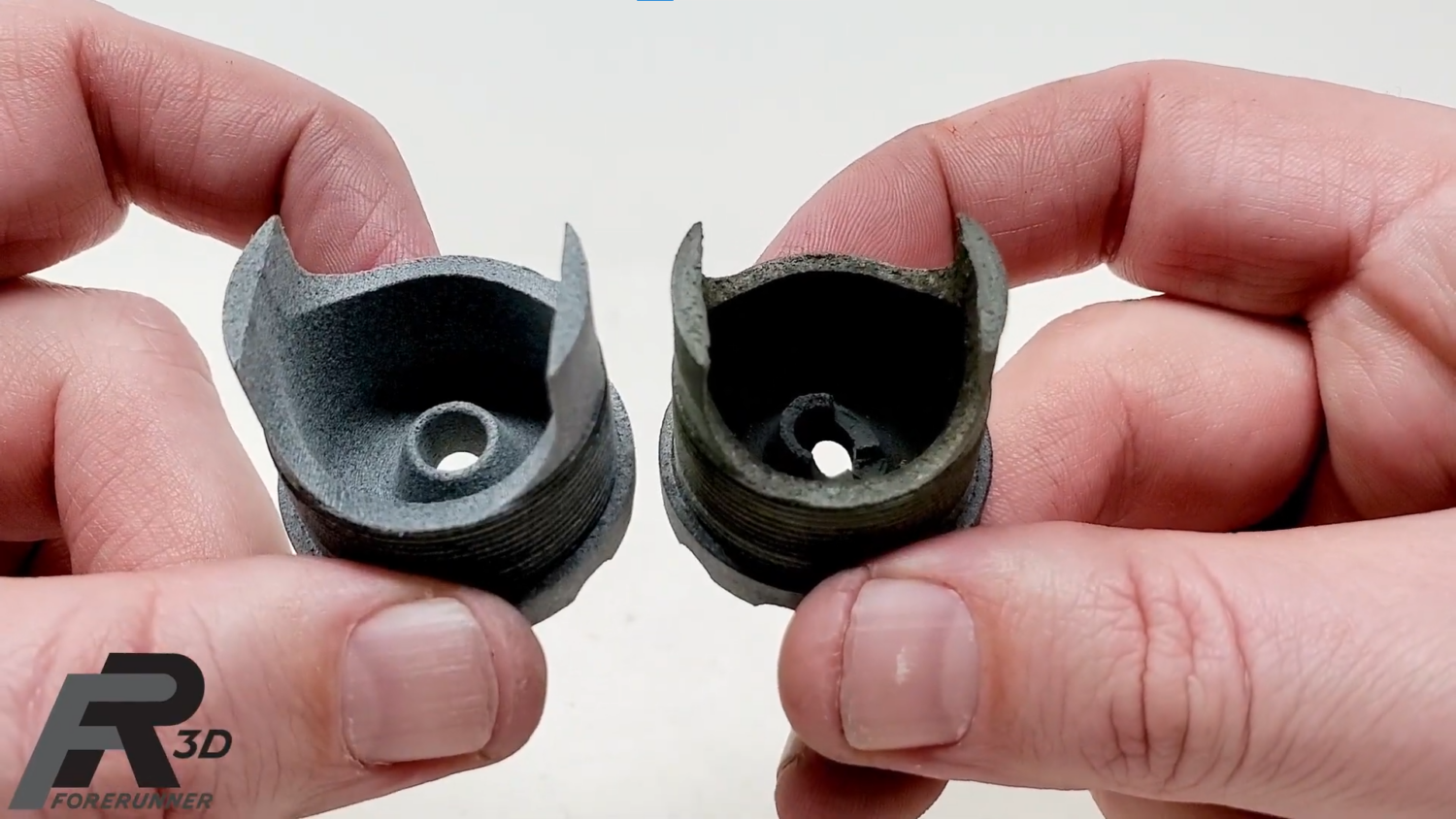

The silencer used in the test is not entirely polymeric, the tube and threaded end cap are titanium, while the blast chamber diverter and the primary blast baffles are aluminum. The mono-core baffles and the other end cap are printed in Nylon 12.

The design is meant to test the strength of the 3D printed material and it is rated for rimfire use.

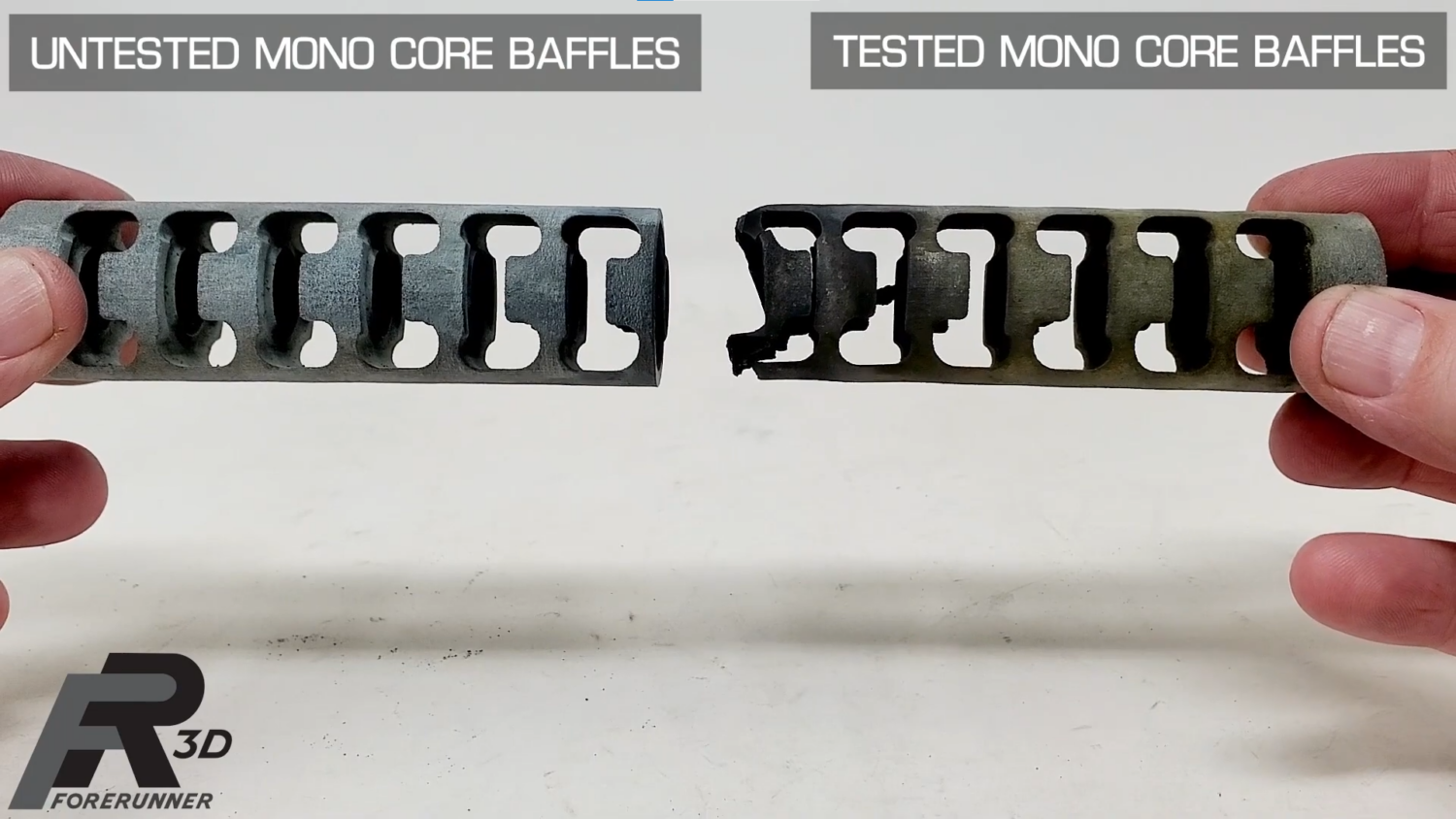

Destructive Testing of a 3D-Printed Nylon Suppressor – The mono-core (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – End cap – (Credit: Forerunner 3D Printing, via YouTube)

The test

With 152 rounds of .22 LR and 69 rounds of .22 WinMag out of 5 firearms in total, FR3D unleashed the onslaught on the plastic mono-core.

Destructive Testing of a 3D-Printed Nylon Suppressor – The rimfire “arsenal” – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – Loading up – (Credit: Forerunner 3D Printing, via YouTube)

The silencer appeared to provide the expected level of signature reduction and behaved flawlessly for 75 rounds when a tone change was experienced. The suppressor however kept its integrity and FR3D kept shooting.

Destructive Testing of a 3D-Printed Nylon Suppressor – Tone change – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – Nicholas C approved – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – Still looking good – (Credit: Forerunner 3D Printing, via YouTube)

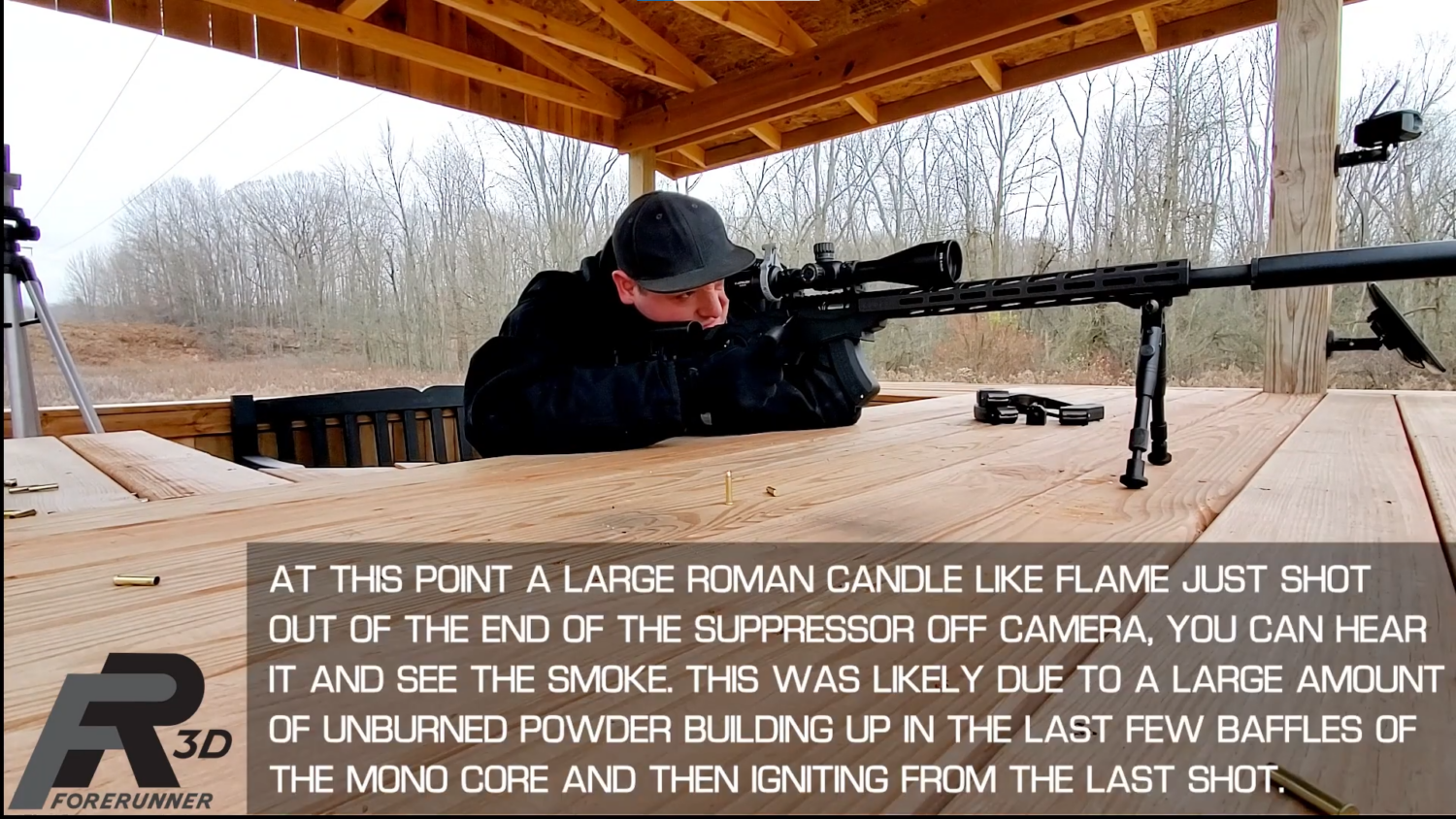

During the testing with the .22 Magnum rifle, there was a “Roman candle” event, likely due to unburnt powder within the mono-core. The rifle was reportedly still able to consistently hit the target at 250 yards up to the last shots. A quick inspection at the range showed a large amount of unburnt powder in the core chambers.

Destructive Testing of a 3D-Printed Nylon Suppressor – Roman candle – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – Unburnt powder – (Credit: Forerunner 3D Printing, via YouTube)

The aftermath

The inspection after the range session showed badly damaged components but fully proved the robustness of the parts and the manufacturing process, cementing the concept that MJF is a fully viable solution for less stressed items such as the ones that FR3D offers on their website.

Destructive Testing of a 3D-Printed Nylon Suppressor – Mono-core after – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – Mono-core after – (Credit: Forerunner 3D Printing, via YouTube)

Destructive Testing of a 3D-Printed Nylon Suppressor – End cap after – (Credit: Forerunner 3D Printing, via YouTube)

You can find the full video here:

Conclusion

What do you, TFB readers, think about this test? Were you expecting such a performance or rather an early kaboom? Would you trust MJF parts on your firearm?

Your Privacy Choices

Your Privacy Choices