In three previous articles, we briefly discussed some of the tradeoffs involved in the bullpup concept, and some of the challenges they face in the field of military procurement specifically. Today, we’re going to continue this deep-dive into the bullpup concept by examining how the selection of either a bullpup or conventional layout affects concurrent development of a new ammunition system. In other words, we are going to address the question: Given the same performance requirements, how does having a longer or shorter barrel affect the characteristics of a new type of ammunition?

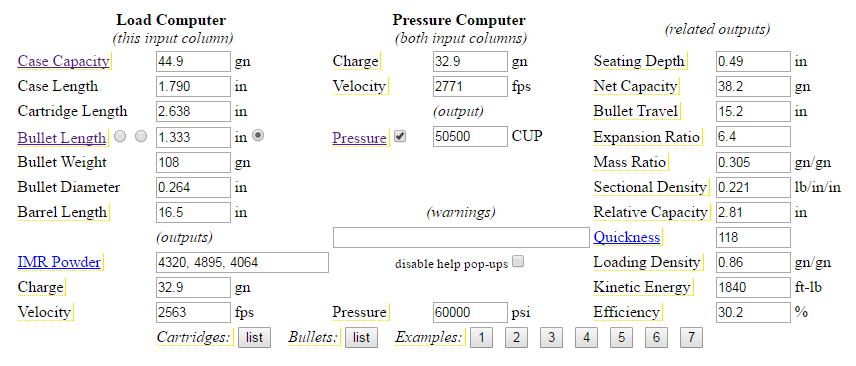

To do this, we need a couple of tools. The first is the method I outlined in an October of 2014 post on modeling cartridges cases in SolidWorks. The second is an online Powley computer for controlled performance estimation. In addition to that, it’s handy to have calculators for recoil impulse and platoon ammunition weight, as these will be the two chief elements affected by the different sized ammunition we will be modeling.

Now, for the purposes of example, we will need an ammunition performance baseline. In this case, I chose the “General Purpose Cartridge” configuration proposed by Anthony G. Williams, since it’s a mid-sized round and makes platoon ammunition calculations easier. His concept calls for a 108gr (7g) .264″ (6.5mm) projectile fired at a muzzle velocity of 2,770 ft/s (845 m/s), therefore those are the figures our rounds will have to meet. I also opted to model only brass-cased rounds, as that was easier and would also magnify the weight disparity between the rounds. Finally, I needed to choose a set of barrel lengths. 20 inch barrels seem reasonable for bullpups (and are preferred by Williams as per his concept), which allows us to derive an equivalent barrel length for a conventional rifle. The bullpup layout generally allows an additional 6-8 inches of barrel length for a given overall length, but this assumes a conventional with a full-length stock. Since most modern conventional rifles sport collapsible buttstocks – a feature essentially incompatible with modern bullpup designs – I used a penalty of 5.5 inches for conventional rifles. This gives us a barrel length of 14.5 inches. It is also reasonable to suggest that a military force may be comfortable with a slightly longer barrel (e.g., the USMC’s M27 IAR) if improved performance followed, so I also did the calculations for 16.5 inch long barrels.

With these baselines in place, it was possible to model three different cartridge cases which could meet the performance requirements at each barrel length:

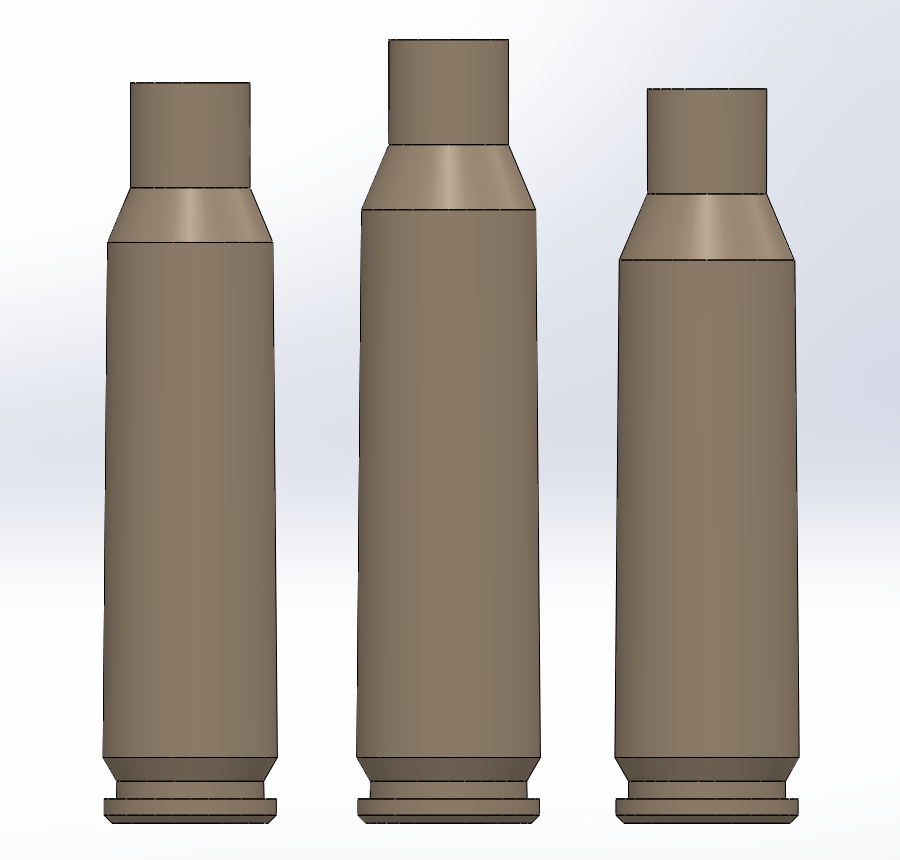

To create these models, place holder figures were entered into the Powley computer at a set peak pressure and the case capacity adjusted until the 2,770 ft/s velocity figure was reached. Then, a sketch of a cartridge case was created in SolidWorks for each round, and adjusted until the measured case capacities matched those in the Powley sets. To perfect each model, the Powley calculations and cartridge models were the adjusted via trial and error until their figures matched. The resulting cartridge cases are shown below:

Left to right: The 20″ barreled bullpup GPC case, the 14.5″ barreled conventional GPC case, and the 16.5″ barreled conventional GPC case.

For the 20″ barreled bullpup case, I used a custom case head 0.422″ in diameter at the head and 1.805″ in length. For the 14.5″ and 16.5″ barreled conventional cases, I used a case head 0.445″ in diameter at the head, and 1.910″ and 1.790″ in length, respectively. I deemed the difference in case head diameters reasonable, as it would fully illustrate the weight reduction possible with a longer barrel better, due to the reduced amount of material present in the smaller case head. With similar sized heads, the shorter barrels would have resulted in excessive cartridge overall length. For the two different sized cases, wall thickness was adjusted to maintain hoop strength of the brass. Besides the case head diameter and wall thickness, all other relevant parameters (e.g., rim and extractor groove dimensions, case taper, shoulder angle, neck length, primer size) were kept constant.

The completed case models had the following masses:

GPC-Bullpup – 119 grains / 7.70 grams

GPC-Conventional – 133 grains / 8.59 grams

GPC-Conventional (16.5in) – 127 grains / 8.29 grams

To estimate propellant mass for each round, it was assumed that propellant would be loaded at an approximate mass-volume density of 1.02 for a given net capacity. This was done because Powley does not adjust propellant load data based on pressure, and so substitute figures had to be derived.

Estimated propellant masses:

GPC-Bullpup – 35.0 grains / 2.27 grams

GPC-Conventional – 42.9 grains / 2.78 grams

GPC-Conventional (16.5in) – 38.9 grains / 2.52 grams

Using the performance and propellant figures, I was able to calculate the recoil impulse for each round:

5.56mm NATO – 1.28 lbf-sec

GPC-Bullpup – 1.95 lbf-sec

GPC-Conventional – 2.09 lbf-sec

GPC-Conventional (16.5in) – 2.02 lbf-sec

7.62 NATO – 2.61 lbf-sec

With the case and propellant masses established, complete round masses could then be derived. Note that each assumes the mass of a small rifle primer is 0.25 grams:

GPC-Bullpup – 266 grains / 17.22 grams

GPC-Conventional – 287 grains / 18.62 grams

GPC-Conventional (16.5in) – 279 grains / 18.06 grams

Using a modified version of the previously linked ammunition load calculator, I was able to account for the differences in total ammunition load carried by the platoon. I used figures of 25 rounds per magazine, 2.9 grams per link for the 20″ barreled GPC round (the smaller diameter case allows for lighter links) and 3.4 grams per link for the 14.5″ and 16.5″ barreled GPC rounds, and 150, 155, and 160 grams per magazine for the 20″, 16.5″, and 14.5″ rounds, respectively. The results were:

GPC-Bullpup – 355.534 kg

GPC-Conventional – 386.634 kg

GPC-Conventional (16.5in) – 376.022 kg

These figures together establish the degree to which the longer barrel as afforded by a bullpup layout allows smaller and tamer ammunition to be developed for the same performance. As some of our readers may have already guessed, the resulting difference does not seem to be very great. The 14.5″ barreled conventional round carries a recoil impulse penalty of just 7%, the 16.5″ barreled conventional round barely 3.5%. The penalty in terms of round mass is just over 8% for the 14.5″ round, and less than 5% for the 16.5″ round. When the entire platoon’s load is accounted for, the penalties are 8.7% and 5.8%, respectively.

This means that, versus the 20″ barrel, choosing a 14.5″ barrel as the standard for a new ammunition’s performance specifications results in an additional 31.1 kilograms (68.6 lbs) carried by the platoon, which is an average of about 0.8 kilograms (1.8 lbs) per member of the platoon. With a 16.5″ barrel as standard, the penalty drops to 20.5 kilograms (47.2 lbs) or 0.53 kilograms (1.2 lbs) per platoon member.

To add perspective to these figures, I modeled the 14.5″ barrel GPC round with a conventional steel case, instead of brass. This resulted in a case weight of just 7.2 grams, and a round weight of 17.23 grams, nearly identical to that of the 20″ barrel GPC round.

From this analysis, I leave the reader to make their own decision. If a new round is to be designed, is it worth it to accept a longer-barreled bullpup, or are the differences not great enough to justify the concept?

Your Privacy Choices

Your Privacy Choices