A CAD program is a powerful tool, and can be extremely useful for the amateur handloader and cartridge designer. One of the things that I find most handy in the context of experimenting with hypothetical wildcat cartridges is using SolidWorks or another analytical CAD program to find the internal volume (case capacity) of a given round of ammunition. To do this, you’re going to need a drawing, or at least a very good guess, of the cartridge case itself. Keep in mind that cases change dimensions over their lifespan from trimming the case neck until they are spent brass; what we’ll be measuring here is the effective case capacity of an empty, unfired case.

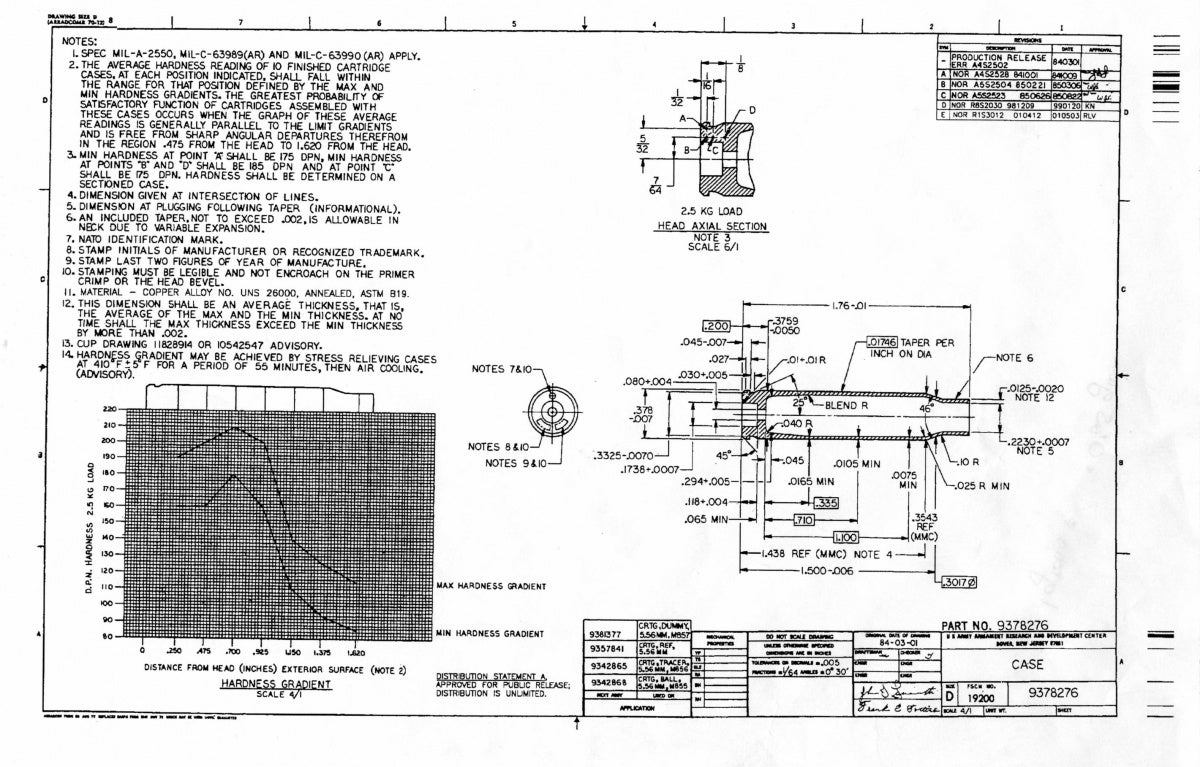

For the example in this post, we’ll use 5.56x45mm NATO, comprehensive drawings of the case being available online. The one I’m using is found below:

From this drawing, I created a single part in SolidWorks representing the case itself. This is very, very easy, and simply involves drawing half of the cross-section of the case itself (axis line included), split down the center of the flash hole, and using the “Revolved Boss/Base” tool, select the axis of revolution, then the contour (which will be the cross section of the case). Be sure to uncheck the box next to “Thin Feature” before hitting the green checkmark that will give you your finished case.

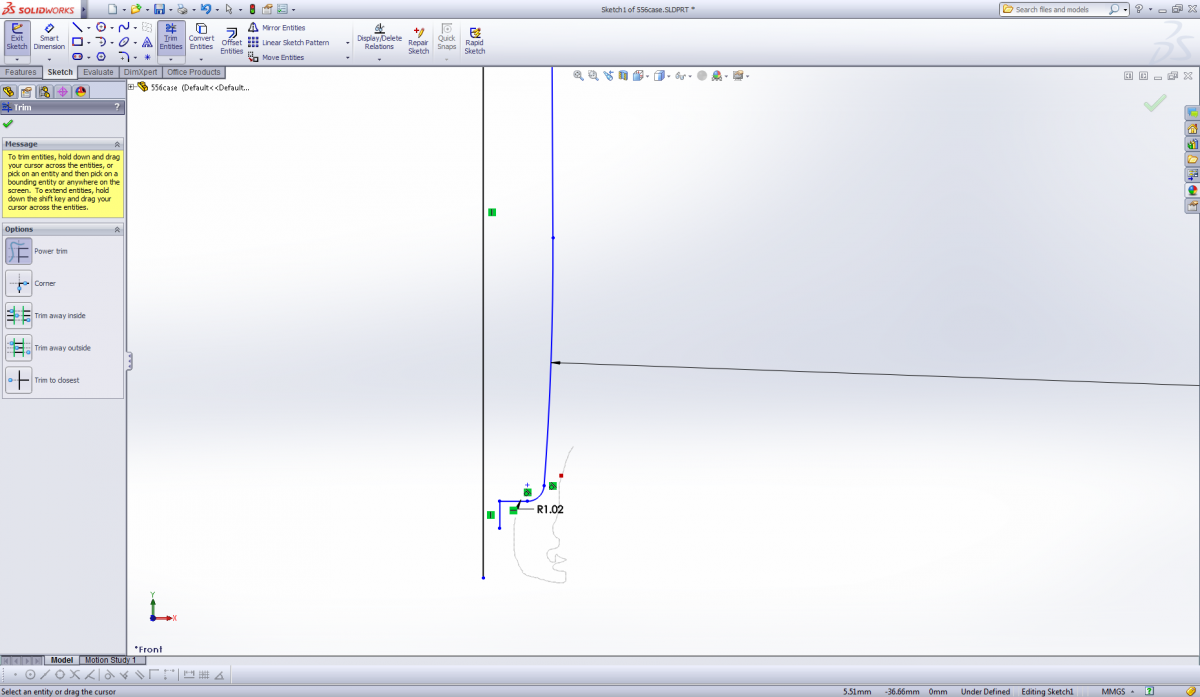

Click the image to expand. It’s important to have the axis of revolution centered properly, or else your volume will not be right.

Select the contour to create your case. Notice that “Thin Feature” is selected; deselect it before hitting the green checkmark.

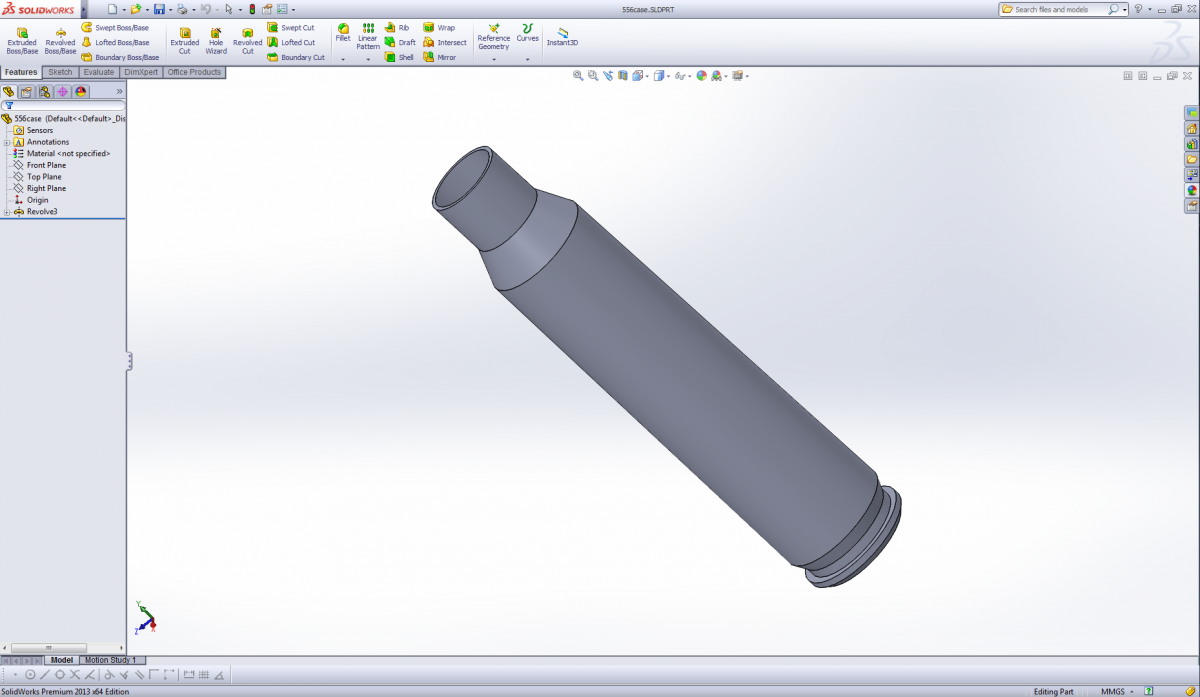

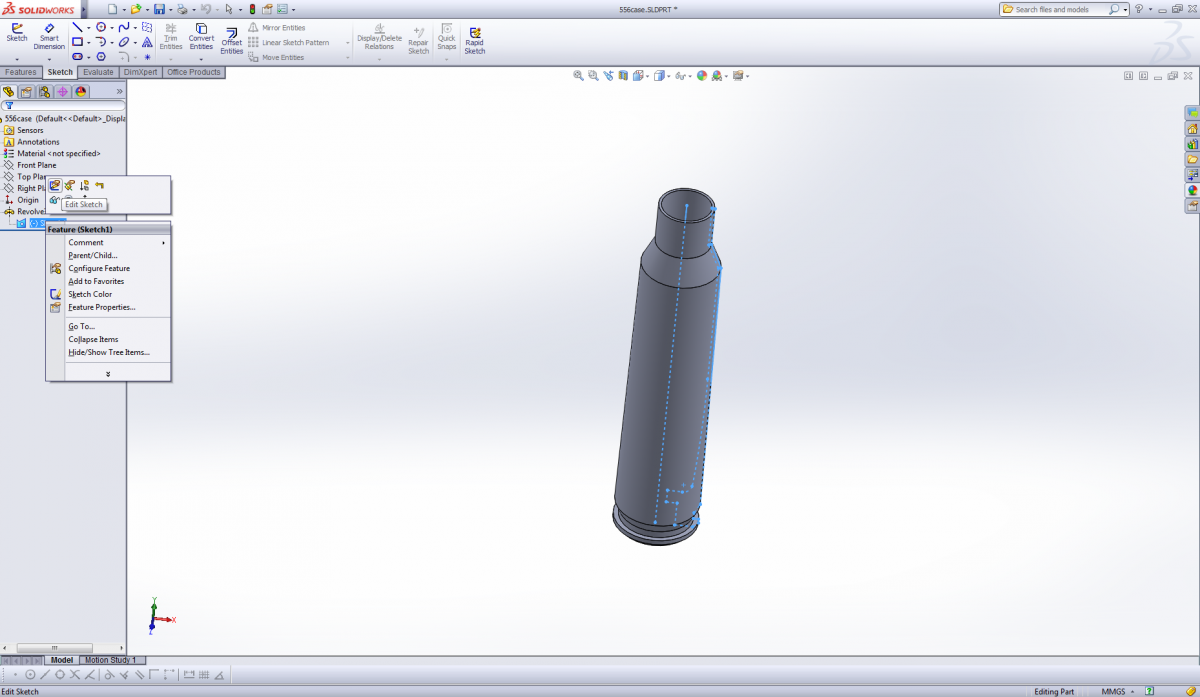

The finished case is useful for many things, but it’s not what you want to find the case capacity itself. To find the volume inside the case, go to the parts tree and right click to reveal an “Edit Sketch” button. Left-click, and you’ll be able to access your sketch again.

Editing a sketch to find the case capacity will save you a lot of time. The errors you get from doing this can be unsettling, but with proper correction, won’t harm your work.

Now it’s time to cut away everything that doesn’t represent the case volume. Select the “Trim Entities” tool, then select the “Power Trim” option, to cut away the outline of the case, leaving only the case volume. Be sure to leave the volume of the flash hole intact, but not the volume for the primer.

Complete the volume by attaching the contour to the axis of revolution, and then hit “Exit Sketch”. A prompt will appear; just select “Exit the sketch and rebuild anyway”. This will open another panel telling you there’s an error, just close it. Now, right click the Revolve tab on the part tree, which will have a large stop sign with a white X through it, and left-click “Edit Feature”. Now highlight the “Selected Contours” box, and select the case volume. Hit the green checkmark, save under a new name, and now you have modeled the case capacity of your cartridge in SolidWorks.

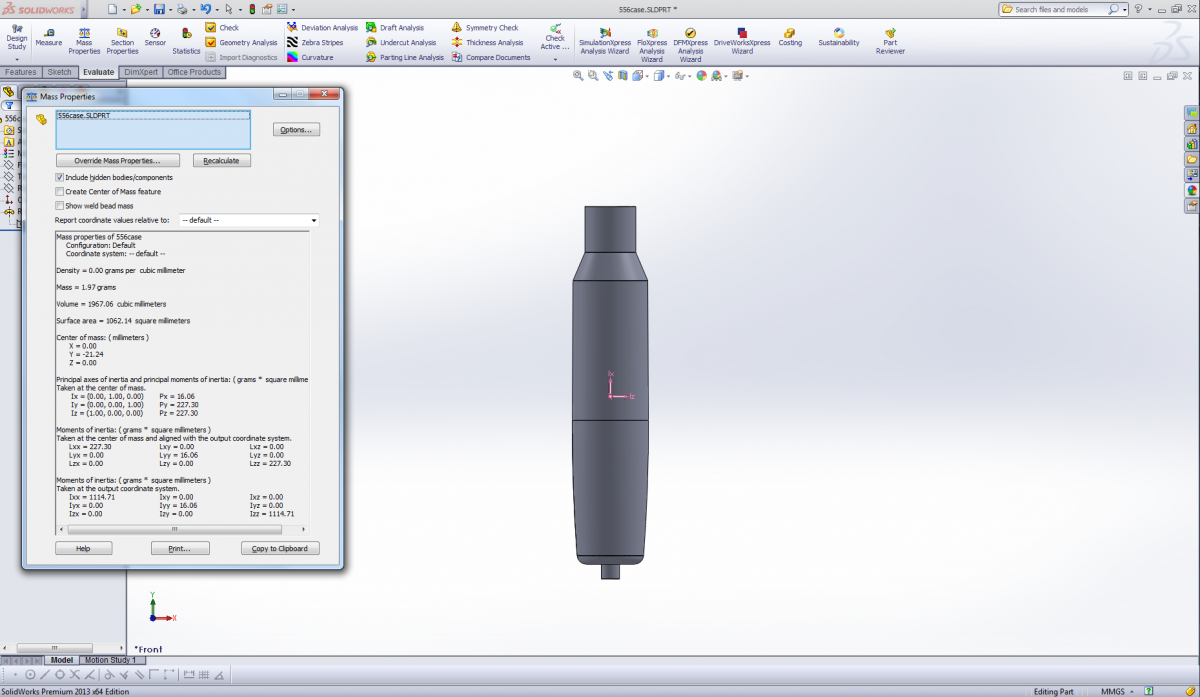

To find the capacity itself, click the “Evaluate” tab and select the “Mass Properties” option. To find the volume in grains water, simply take the number given for “Volume” divide it by 1,000, and then multiply it by 15.43. Our 5.56mm case model gives us 30.35 grs H2O case capacity, which is pretty accurate!

Your Privacy Choices

Your Privacy Choices