One thing I love about the guys at Strike Industries is that when they come up with an idea they don’t think is worth commercializing, they release the idea for free to the internet. One of their engineers, Sam C., who is an H&K G36 fan, came up with a handguard/rail concept that could prevent the loss of zero that the German military claims happens when the H&K G36 heats up. They have allowed me to publish the design and told me that any manufacturers can use it royalty free (if any manufacturers want to confirm this or want more details about the design they can email info@strikeindustries.com).

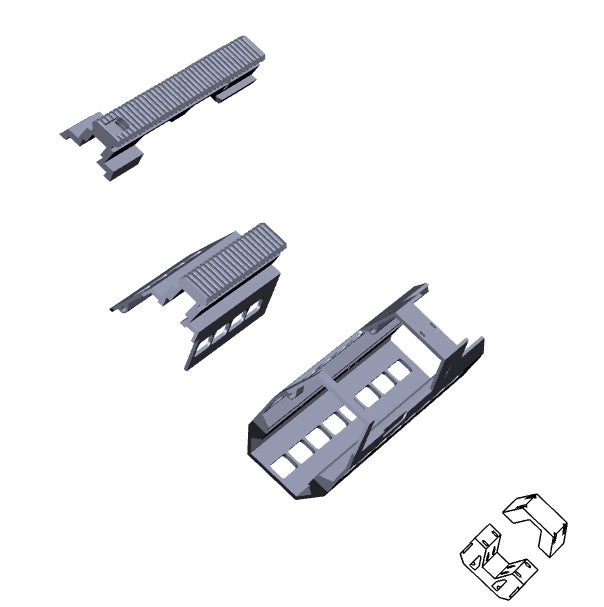

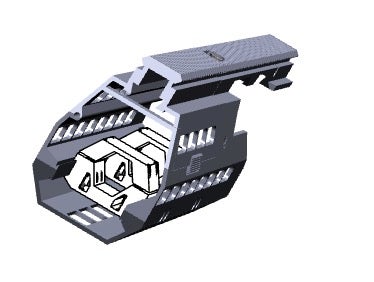

Sam’s idea is a barrel clamp combined with a new handguard. The CAD render below shows the new parts and the clamps Sam designed. I have rendered the clamps differently to the rest of the handguard so you can see them better.

The lower half of the clamp slots into dovetails on the lower handguard and is bolted into place from the side of the lower handguard. The upper half of the clamp is bolted over the rifle barrel.

In this CAD render I have shown the barrel so you can see how it all fits together ….

Sam also designed an optional top rail cover which can be opened for easier access to the gas piston block.

There are two downsides to this rail. The first is that the barrel no longer free-floats. Because the free-floating system has accuracy problems I don’t see this as a disadvantage as long as the clamp system improves accuracy. The other disadvantage is that the SI rail is bulkier than the factory G36 rail and would be heavier with the relatively large clamps inside.

A big thanks to Strike Industries allowing us to share this design with you. Last week we reviewed one of their upcoming handguard designs. You can read the review here.

Our own Alex C. got hold of an H&K to see if he could replicate the accuracy issues. The video can be watched below …

Your Privacy Choices

Your Privacy Choices