If we can make a round that is significantly better than the existing 5.56mm or 7.62mm ammunition, shouldn’t the military just bite the bullet and switch, to the benefit of the servicemen and women in harm’s way? What’s stopping the powers that be from making the incremental improvements that everyone knows are possible?

Strap in, because the answer to this one is not so simple.

In the fall of last year, we spent some time talking about caliber systems, and how something that seems simple enough on the surface (cartridge goes into gun, gun fires, feeds another cartridge) is actually an extremely complex interconnected system involving millions of weapons (often of multiple types) and billions of rounds of ammunition, including several different varieties like tracer, ball, armor piercing, etc. The nature of this complex system means that some ideas that work for handloaders and tinkerers in the small scale either don’t work or are too impractical to be implemented in large scale, such as the kind of industrial production required for military weapons and ammunition.

Many ideas, however, are not themselves impractical for military weapons or ammunition. Low drag bullets, higher relative capacity cartridge cases, and other features are not intrinsically incompatible with a war machine producing billions of rounds per year. Rather, the problem with these ideas is what I will call “the home team advantage”: Established infrastructure is so important, and so difficult to change, that anything that requires a major change to it is at a massive disadvantage from the start. This means that in order for such a change to be worthwhile, it has to offer not just a significant or measurable advantage, but a transformative one.

Let’s take for example an improved low drag round like Federal’s newly released .224 Valkyrie. In previous articles, I have sung the praises of this new round for being extremely well-designed and efficient, lacking many of the flaws of previous rounds like the .22 Nosler or 6.5 Grendel. With a much longer projectile ogive, and a higher relative capacity, a round like the .224 Valkyrie would fly flatter, hit harder, and buck wind better than existing 5.56mm ammunition, at little or no weight penalty. On the surface, it seems like a no-brainer.

Left to right: .224 Valkyrie, .22 Nosler, 5.56mm Mk. 262, and 6.5 Grendel. Note that the Valkyrie’s case is shorter and wider than that of the 5.56mm, necessitating special barrels, bolts, magazines, belt links, and other components.

However, the .224 Valkyrie is not a drop-in fit for existing 5.56mm M4 Carbines and M249 SAWs. Due to its fatter, shorter case it cannot fit in standard 5.56mm chambers or belt links, and will not feed from 5.56mm magazines properly. While for a civilian shooter these are minor inconveniences – they simply would need to buy a few new magazines and a new bolt and barrel – for a large military user, these changes present a much more significant obstacle to adoption. To adopt a round like this, a military user would have to change not only their ammunition stockpiles (measured in hundreds of millions or billions of rounds), but all their ammunition magazines (millions of units), belt links (billions of units), barrels, bolts, buffers (each being in the hundreds of thousands of units), stripper clips (tens of millions), packaging materials, etc. The development and procurement of each new item would likely be its own program in microcosm, meaning development of the system as a whole would take years of time and billions of dollars to implement. Consider that, from conception to first implementation, the 7.62x51mm NATO round took thirteen years to develop, from the time Col. Rene R. Studler sent out a memo to Frankford Arsenal in 1944 to the adoption of the M14 rifle and M60 machine gun in 1957. The 5.56mm round, on the other hand, took far less time to develop – only a couple of years – but its introduction with the M16 was a disaster that overshadowed even the highly controversial protracted development of the 7.62mm M14. It seems unlikely, therefore, that the introduction of any new round today could be conducted both quickly and painlessly.

There are many reasons the introduction of a new caliber, especially one intended for existing weapons via a retrofit, would be a complex and drawn-out affair. First and foremost is the fact that a commercial ammunition specification is wholly insufficient for military ammunition (something proven beyond any doubt by the introduction of the M16 rifle in Vietnam, where “off the shelf” commercial data adopted as military standards led to failures of the rifle-ammunition system in combat). This means that a new, much more detailed specification must be written for any round that is to be adopted – effectively meaning that an entirely new and different round must be designed from the start. Compare the 5.56mm and .223 Remington: Even though there is some degree of interchangeability between the two, they are each effectively different chamberings, with both the chamber and an ammunition held to substantially different standards. Therefore, the shorthand way of saying “the military should adopt the .224 Valkyrie” does not reflect what we would really be asking for. It would be more accurate to say “the military should endeavor to develop from the ground up comprehensive standards and materiel for a round similar in design to the .224 Valkyrie”. Quite the mouthful!

Besides the ammunition standard itself, there must also be equally comprehensive standards for the weapon components designed to fit the new round. Retrofitting the M4 Carbine for the .224 Valkyrie, for example, would require new barrels, bolts and magazines, but it would also likely require a new buffer design, new gas tubes, and other components. Depending on the design of these components, such a change could also require many other new parts – for example, a polymer magazine designed for the .224 Valkyrie would likely require entirely new upper and lower receivers to accept it. Not only that, but most new components (like bolts, for example), would need to be made incompatible with other legacy parts to prevent misuse. One could easily imagine a private bringing his rifle into the armory to diagnose why it won’t extract, and the armory discovering that his 5.56mm gun has the bolt for the new, wider caliber, instead of the legacy unit. This means that even more new components would need to be introduced, to the point where any such new caliber program would de-facto result in a new rifle program, rather than just a “retrofit”. The same would probably be true for existing machine guns and other 5.56mm weapons – either entirely new weapons would need to be procured, or the conversion process would need to be so thorough as to save little time and money versus a new procurement program.

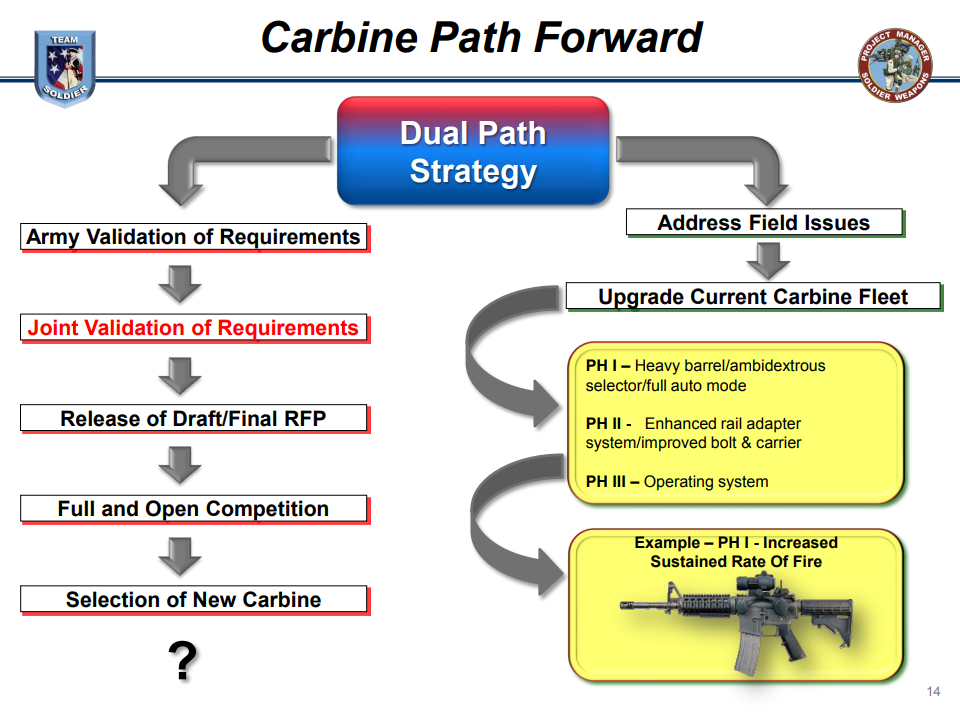

This isn’t to say that retrofitting the existing fleet for a new round is impossible, but it does seem to invite many problems, and the risk of a protracted and expensive program is very high. Consider for example the conversion of the US Army’s M4 Carbines to the M4A1 standard – a process that involves little more than swapping a few parts in the fire control group and replacing the barrel – has taken over seven years since the decision was made, and is still not complete today.

A slide describing the plan to upgrade M4 Carbines to M4A1 standard, from a Project Manager Soldier Weapons briefing from May 18, 2010.

This is a pretty grim picture for those hoping that their favorite round will be adopted by the US military, but none of this means that something new will never be adopted. Rather, it illustrates that an improvement in performance may not be enough to justify the considerable effort required to effect a changeover in ammunition. A more compelling justification would be a new ammunition paradigm that brings to the table benefits not only in performance, but bulk, weight, cost, and other factors. This is what makes plastic cased telescoped (CT) ammunition so interesting, for example. Not only is CT ammunition lighter and potentially higher performance, but the prospect of cartridge cases made from such a ubiquitous resource as petroleum products is extremely difficult to resist. Of course, it’s possible that a new conventional round will be adopted without any advancement in the basic technology at all. Previously, this happened with the 7.62mm NATO, which was not very different from the .30-06 it replaced. Today, many eyes are upon 6.5mm rounds like the .260 Remington and 6.5mm Creedmoor, and already the US SOCOM is planning a roadmap to adopt one of these rounds for their semiautomatic sniper systems.

The bottom line is that change for the military is difficult, expensive, and time-consuming, and when, on the rare occasion, it is none of these things it tends towards the painful and regrettable. Someday, change will come – and that day may even be soon. The question to ask is, then: With all the blood, sweat, and tears it will take, will it still be worth it?

Your Privacy Choices

Your Privacy Choices