3D printing and firearms – a very sensitive subject!

One of the main reasons why people are afraid or against it, is because it’s a new technology and new inventions tend to drive the uneducated into forbidding it (much easier than trying to understand what’s going on). It’s new, so it must be dangerous – and we need new laws!

3D print is “new” in terms of now being affordable to everyone. I realized yesterday that even Apple sells 3D printing machines in their online shop.

Ultimaker 2+ 3D Printer in the Apple Shop

Did anyone ever consider that most, if not all, firearms parts are already produced through some sort of computer aided design, and CNC machines or lathes are used sometime along the production?

So if you have the CAD file you can produce almost any firearms related parts. With various quality, of course, depending on your skills and machinery.

And if you don’t have any of these machines, you can find inspiration from Pakistan.

But if it’s illegal to own a lower, upper, barrel, bolt or whatever the local laws dictate, it’s illegal regardless of the method used to produce it. Just. Don’t. Do. It.

The difference between an affordable 3D printing machine for home use and a professional one is, for starters, several hundreds of thousands of dollars. Obviously there is going to be a difference in quality of the parts that the printer can produce. However, even cheap machines can do some clever stuff.

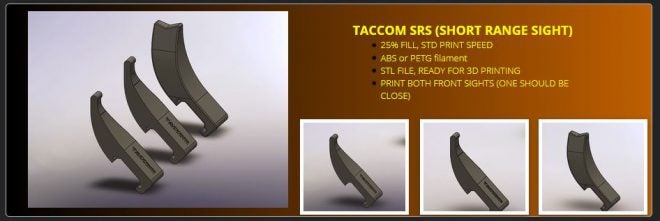

Taccom, LLC in Minnesota USA produce a lot of interesting parts for firearms, especially shotguns, rimfire and AR-15s.

They have a page with a lot of fun downloads, so if you own a 3D printer you can download their design and start producing

The downloads can be found here: http://www.taccom3g.com/downloads.html

I have a hard time imagining that any of these parts would be illegal anywhere.

However, I’m sure they can improve your firearm and aid you in your next competition.

On their Facebook page they recently wrote:

“As promised…in our free download area….the design that IS the Short Range Tactical Sight. We hope to be coming out with this in an adjustable design and and made out of aluminum…..but until then, down load it, print it out slip it on your top rail……you WILL be impressed with how fast it is and how accurate it is as well. This was designed after the express rifle sights used for dangerous game in Africa. We suggest that you use black filament to print this out and then either a white or yellow paint for the front sight ‘dot’. Please let us know how it works for you!!”

“PS…….I’d suggest printing out a couple extra……It’s a printed part!! Probably may not take a barrel hit. But the good news is, it’s free and SUPER easy to replace!!”

Tim Ubl, the owner of Taccom and his background:

“I’ve been in the firearms industry in one form or another for over 20 years. Back when I was 8 years old, my father would take the family out to an old gravel pit and we would spend the afternoon shooting up clay pigeons with model 67 Winchester .22RF rifle. My son now is the proud owner of that very rifle rifle and he learned shoot using it.

I entered into shooting competition years later and being a designer by trade, I used my skills to develop many shooting accessories that are being used by alot of the top shooters today or adapted by police or military operations, infact you are shooting competitively or are in law enforcement, it is possible, that in a way, that I’ve helped you through a match or made your job a little easier. Working for various companies gave myself more exposure to the shooting industry as well as the police and military sector of that industry. I’ve decided to take the huge step of starting my own company to further develop and offer some of the most innovative shooting accessories available. This is a family business and we’ll strive to give you the best value for the dollar, and sensible, usable products and no gimmicks.”

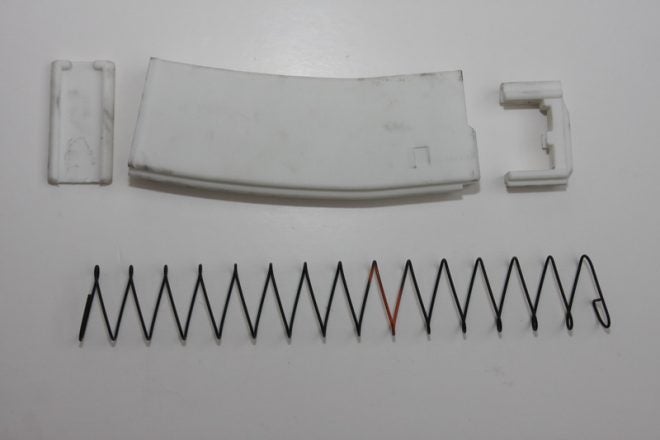

A few years ago, I tested printing an AR-15 magazine. I’m not sure this was the latest revision of the CAD, but it was built in a high-end 3D Systems SLS machine (nylon).

Below you can see Magpul PMAG, 3D print SLS, Lancer and random steel magazine in comparison.

Took the spring (and follower?) from the Magpul. I reckon it would be very difficult to print a spring.

End product below, note the oil and dirt from my rifle.

How did it work? Fit was excellent, but function was not too good. The lips were too thick, so I had to manually sand down the thickness and as I did this there was a problem with the strength. At last it would fire perhaps 5-6 rounds. So it works, but there’s room for improvement.

I haven’t tried any of Tim Ubl’s CAD files, and please note he had nothing to do with the magazine I printed.

Go to Taccoms download zone and get your 3D printers started!

Your Privacy Choices

Your Privacy Choices