Among the interesting concepts that were tested in the mid-late 20th Century is that of an extremely light for caliber, very long bullet made in part of a lightweight material like aluminum and plastic. The 7.92×40 CETME, which if I can find a specimen I will cover later on, is one example, but starting in 1972 the now-closed Frankford Arsenal began experiments on 5.56mm cases loaded with super-long projectiles with von Karman ogives, with the aim of creating a lightweight round using a low-density projectile and an aluminum case. Original testing was conducted with full-length 5.56mm cases and two lengths of bullets, but eventually a shortened brass case and a 37gr bullet with the same shape as the shorter initial test bullet was created. As a solution to the problem of burn-though with aluminum cases, the Arsenal developed a plastic insert called a “flexible internal element” (FIE), and the brass cased rounds developed for ballistic testing also had FIEs. This shorter round in both aluminum and brass cased forms was called the 5.56x38mm FABRL, which stood for “Frankford Arsenal – Ballistics Research Laboratory”, and this at some point was made into a backronym for “Future Ammunition for Burst Rifle Launch”.

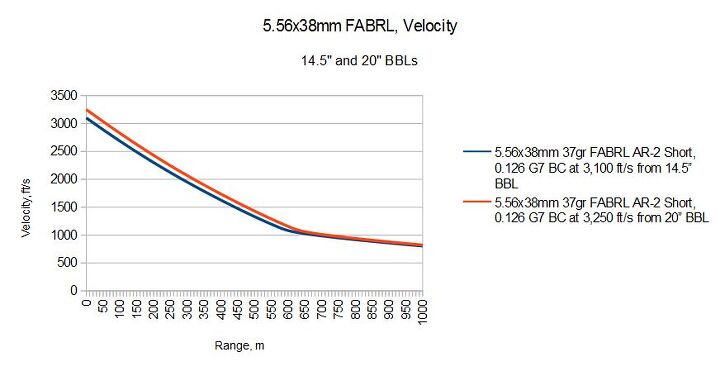

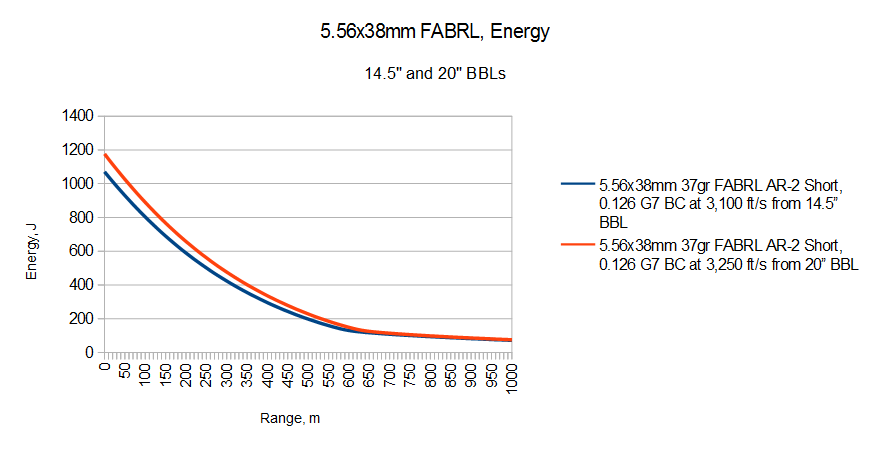

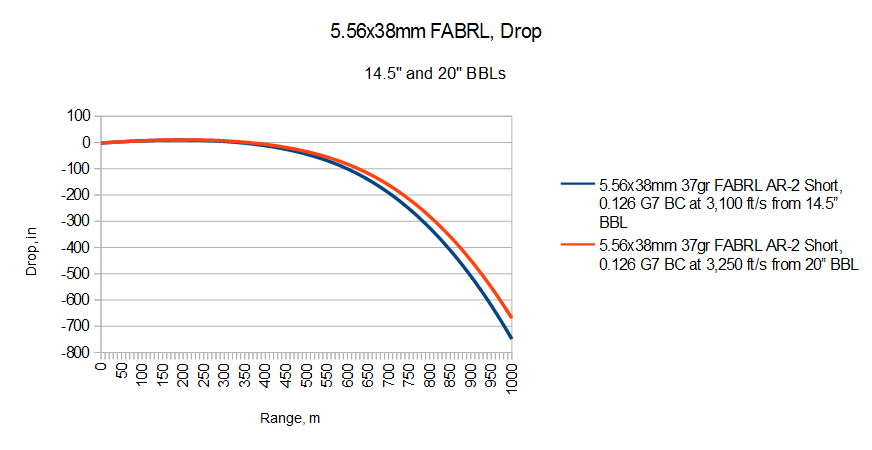

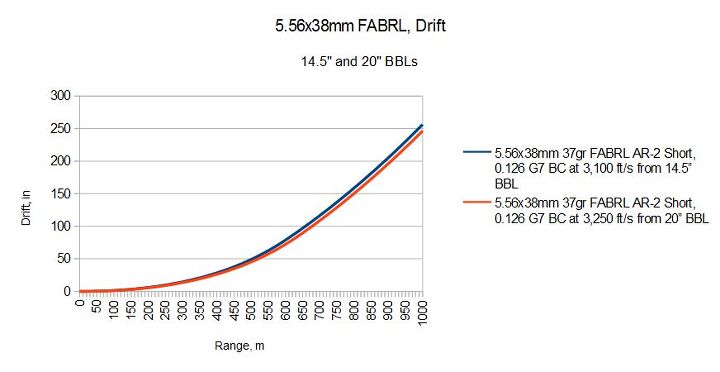

The 5.56mm FABRL’s projectile, due to its shape, has an exceptionally low form factor (0.836 i7), and a resultingly high ballistic coefficient for its weight (0.126 G7). Using G7 for the flat-based AR-2 Short projectile is strange, and I normally would convert into a drag model for flat-based bullets, however I actually have empirical G7 numbers for this projectile from the Aberdeen Proving Grounds, and I do not want to change this data artificially.

One important thing to note is that although I show data for the 5.56mm FABRL out of a 14.5″ length barrel, the cartridge predated the M4 by over a decade and was never tested from barrels of that length.

Ballistically, the 5.56x38mm FABRL essentially equals the 5.56mm M193 in every way except energy, which is about 35% lower at the muzzle, but where this round really shines is in weight. The brass-cased 5.56x38mm round weighs in at about 9.7 grams per shot, and while I don’t have an example of the (very rare) aluminum cased round, I estimate that it weighs about 5.8 grams per shot. That is an enormous 50% reduction in weight versus the M193 round!

Note: All ballistic calculations are done with JBM’s Trajectory calculator, using the ballistic coefficient appropriate to the projectile being modeled, and assuming an AR-15 as a firing platform. Also, keep in mind that there is no single true velocity for a given round; velocity can vary due to a large number of factors, including ambient temperature and chamber dimensions. Instead, I try to use nominal velocity figures that are representative of the capability of the round in question.

Postscript: Since I’ve decided to expand this series to calibers that – while they may still be ballistically relevant to the wider conversation about intermediate calibers – are no longer actually being produced or tested, I have decided to re-name some of the posts in this series to “Historical Intermediate Calibers”. However, I will retain the same numerical sequence and the word “Modern” struck through. Enjoy!

Your Privacy Choices

Your Privacy Choices