One of the firearms I have been wanting to own is an affordable belt-fed. Unfortunately, the Fightlite MCR and the FN M249S are out of my price range. However, a Ciener Belt-Fed AR went up for sale last November by Sven of Manticore Arms so I bought it. In this article we will take a close look at Ciener’s Belt-Fed AR and of course, some modifications and upgrades I made to the system.

Belt-Fed Guns @ TFB:

- POTD: FightLite Belt-Fed Lever Action Rifle

- [SHOT 2023] A Look at Heckler & Koch’s MG4 and MG5 Belt-feds

- SILENCER SATURDAY #258: Subsonic 300BLK M249 – BRM Belt-Fed Joy

Belt-Fed ARs

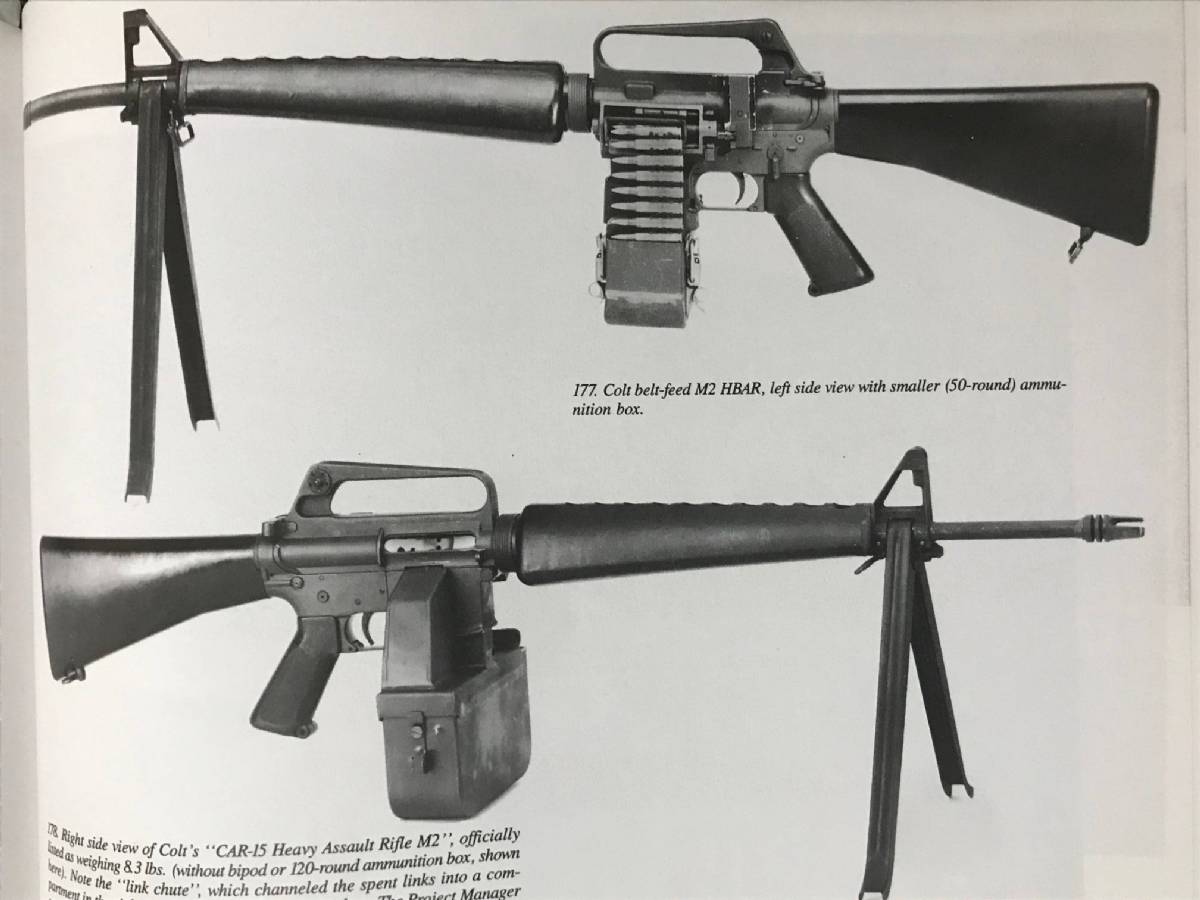

According to a number of online sources, Eugene Stoner made prototypes of a belt-fed based on the AR at Armalite back in the 1950s. But his prototype was built around an AR-10 chambered in .308. Fast forward to the 1960s, Colt scaled down the concept and made a dozen or so prototypes led by Rob Roy. The design did not catch on for the military and the project was shelved.

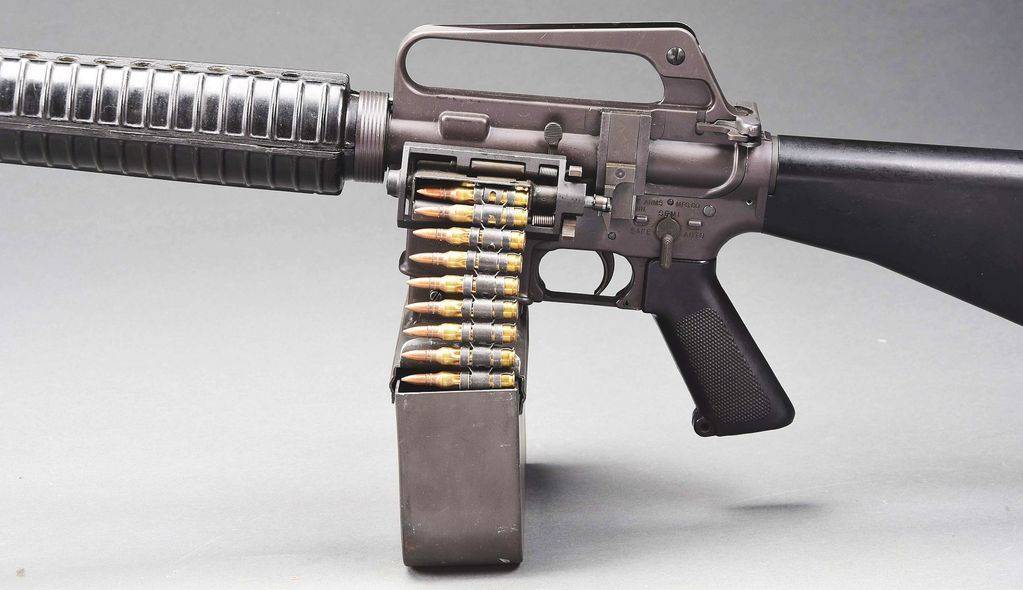

Photo From Morphy Auctions

Photo from Black Rifle pg 175.

Ciener Belt-Fed

Now comes John Ciener in the 1980s where he made these conversions for your AR to turn it into a belt-fed system. He even offered complete conversions. This is one of those guns.

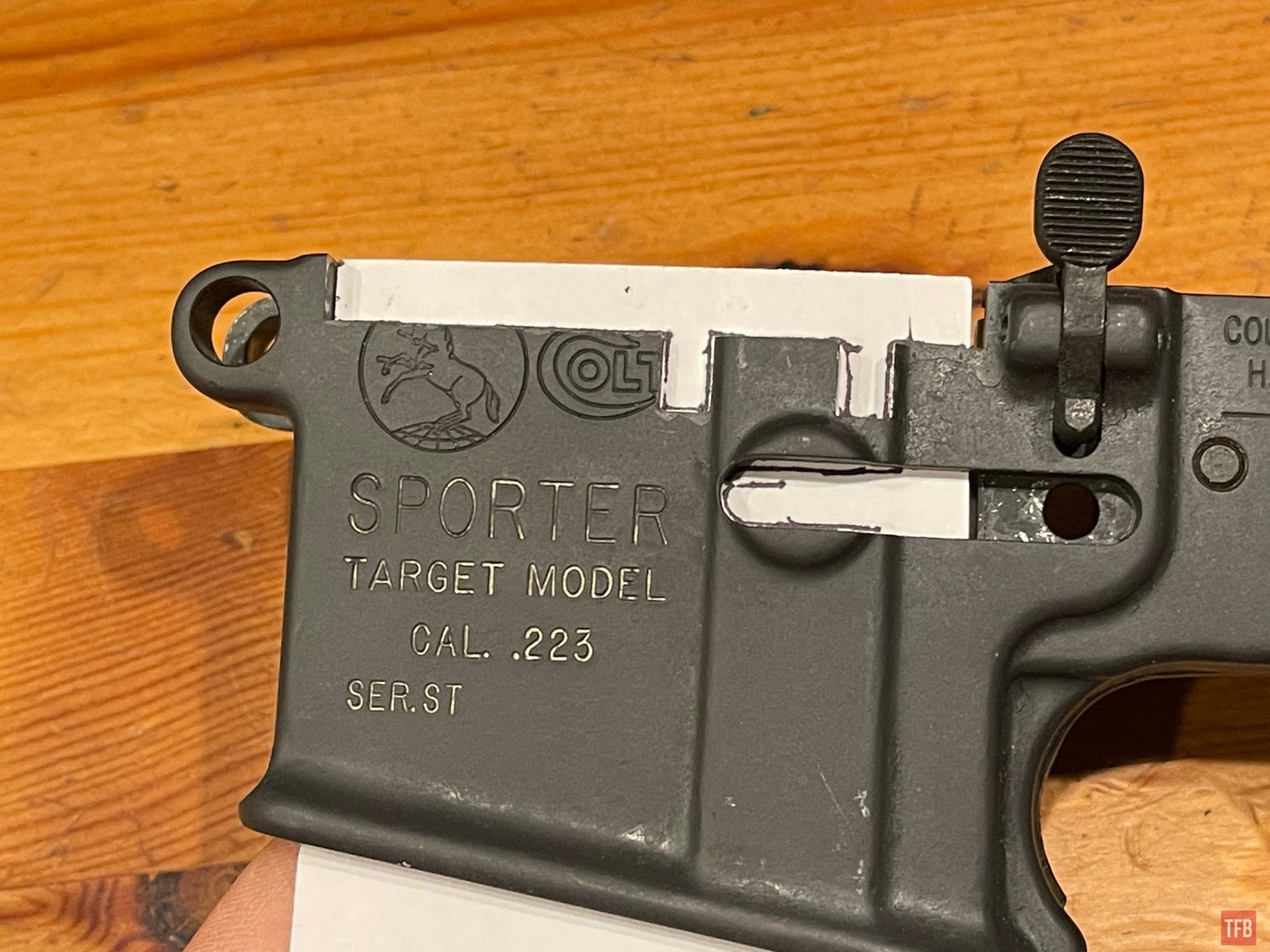

Here are some photos I took when I picked it up at my FFL. This particular Ciener Belt-Fed AR was built of a Colt Sporter Target Model. It was once a carry handle upper but it was milled and a tall weaver rail was bolted on top.

Here you can see the screws he used to fasten the rail to the upper receiver.

Not sure what this is but some sort of epoxy to fill the hole left by the milling of the rear sight.

It is covered up by the dust cover but there is a chute below the ejection port for the spent links.

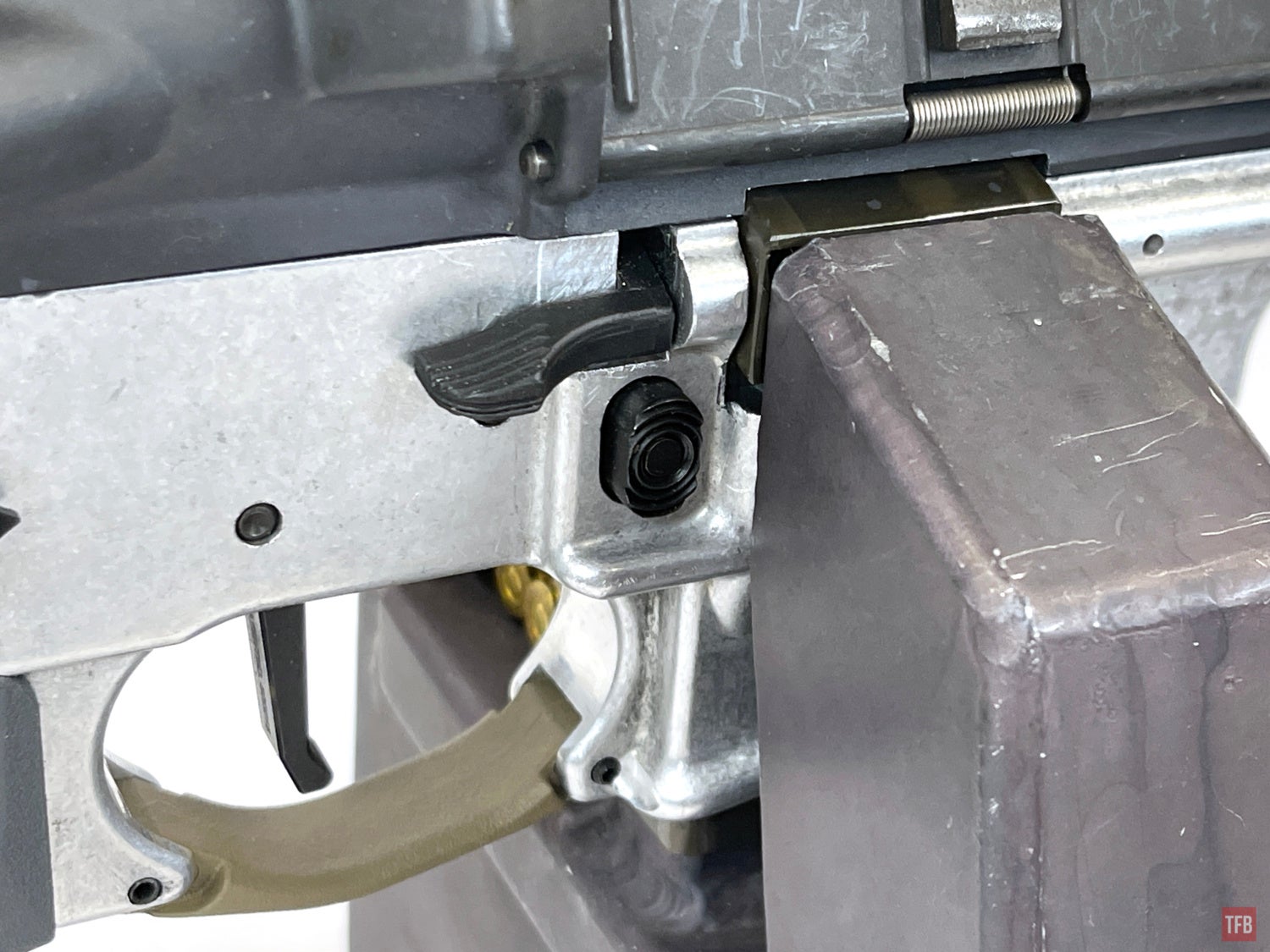

The hole at the bottom of the feed mech box is for pinning the ammo box.

The ammo box for the Ciener belt-fed is similar to the Colt design. The large section next to the mag tower is the collection chute for the spent links.

The ammo box is partitioned so the right side collects the spent links while the left side stores the linked ammo.

With the upper receiver removed, you can see how the feed mech chute lines up with the collection chute.

When the dust cover is opened, the ammo box spent link chute props the dust cover up so it does not interfere with the spent links ejected from the system.

How The Ciener Belt-Fed Works

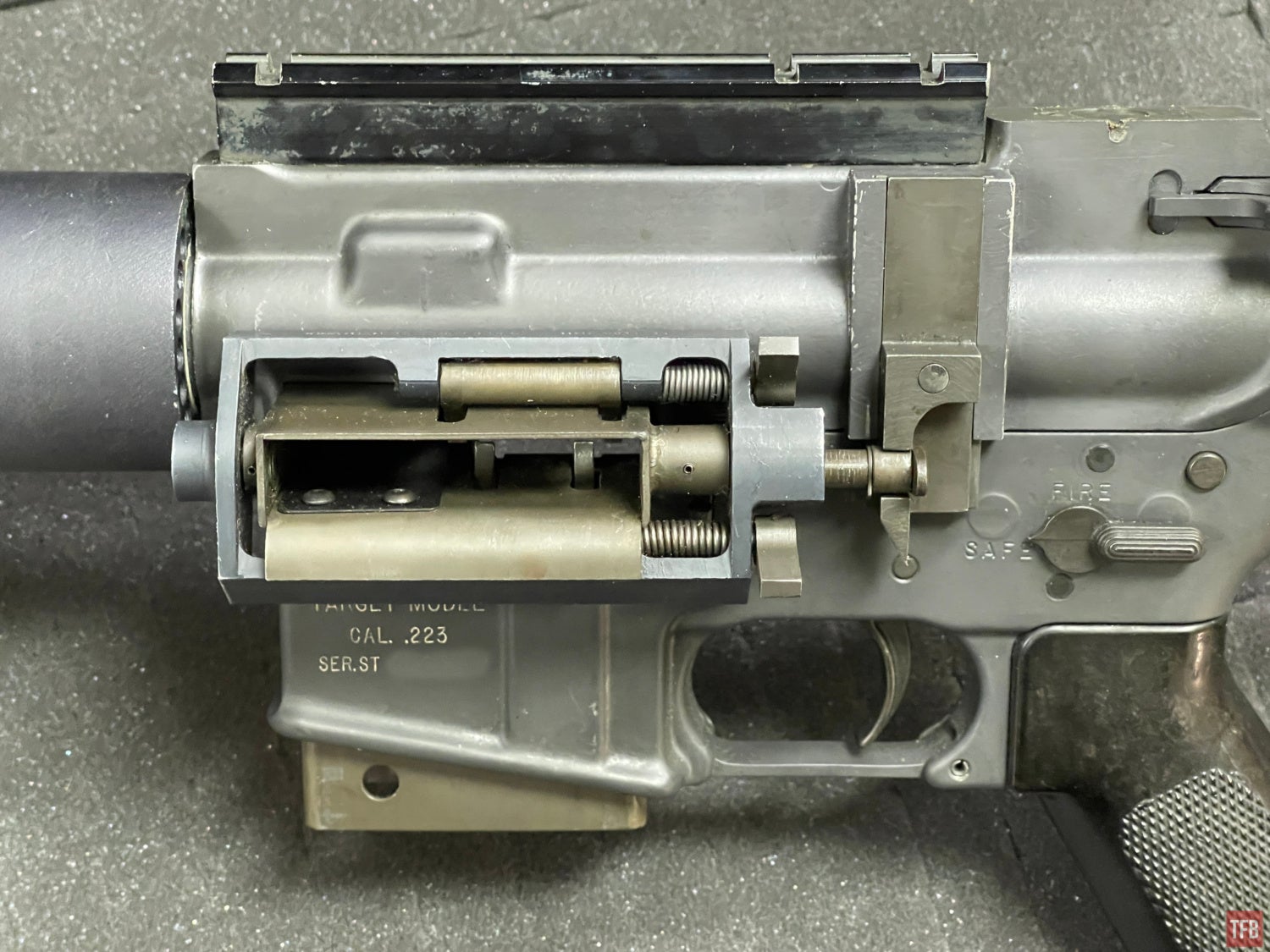

The carrier is modified with a slot that runs along the left side. Note the position of the retaining cotter pin. This will be an important frustration later.

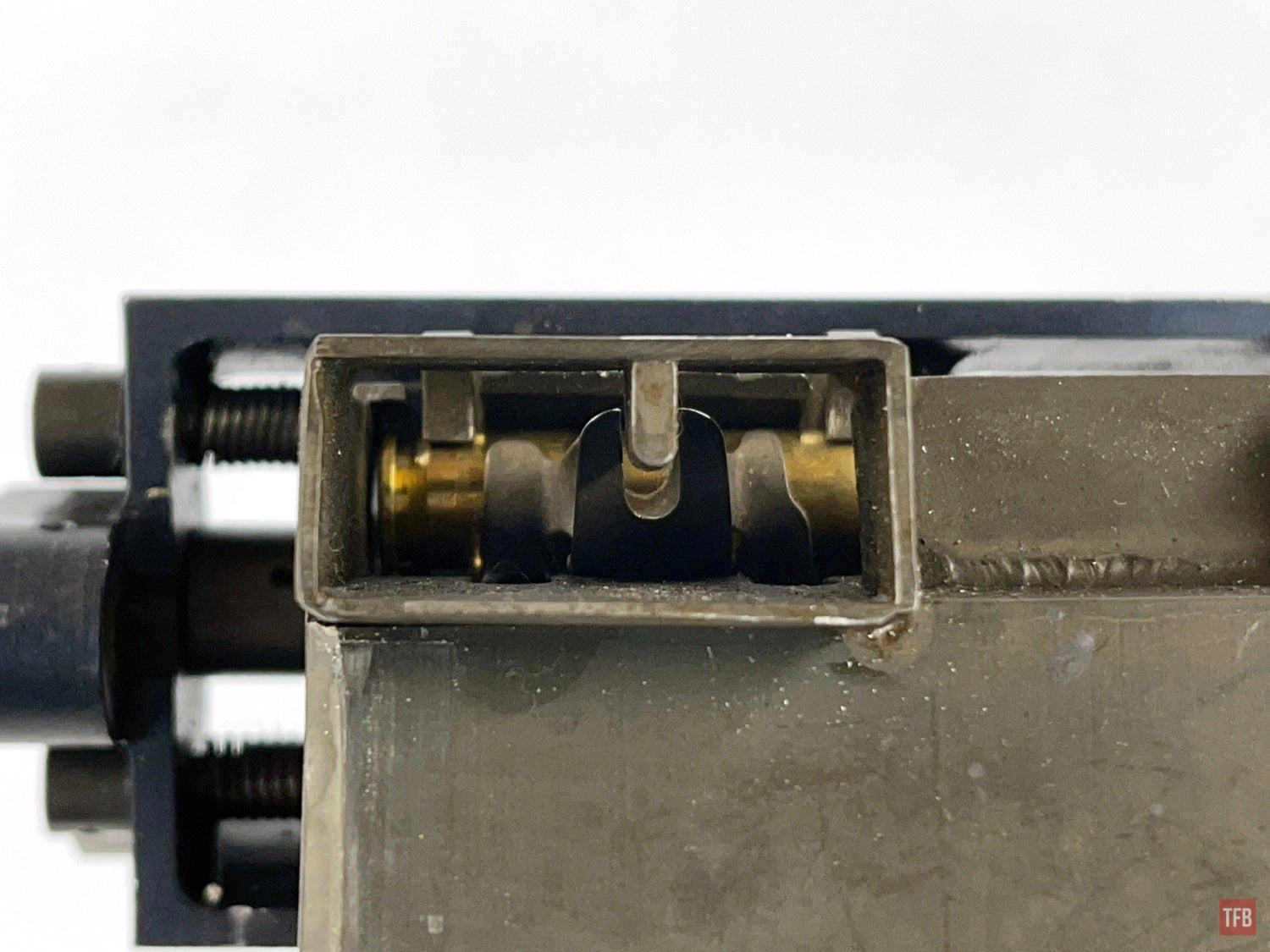

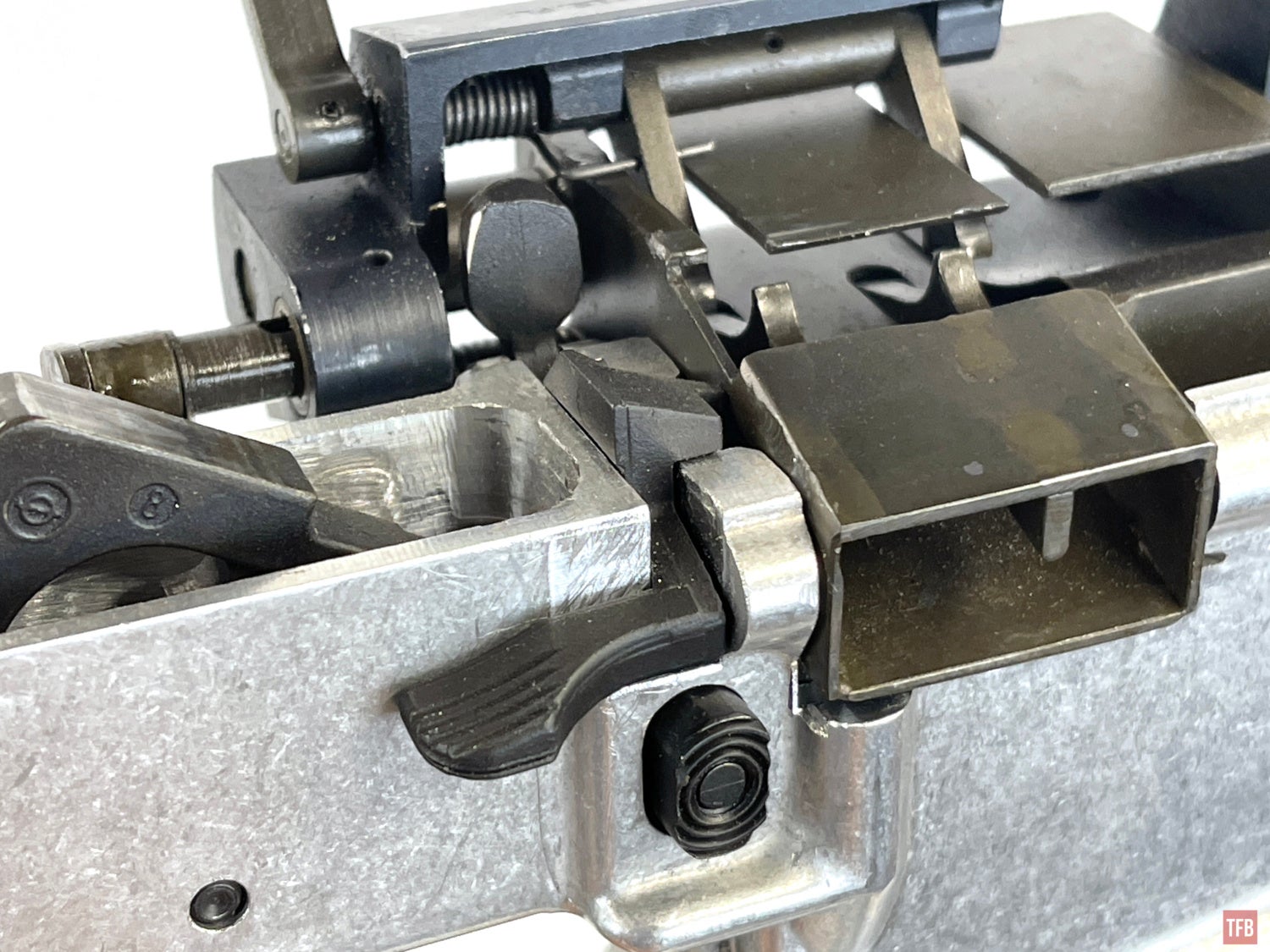

That slot lines up with the drive pin that protrudes into the left side of the upper receiver. The upper has this box welded to it with a shuttle that moves up and down as the bolt carrier cycles.

The box is slotted.

The really clever aspect of the Ciener belt-fed is the orientation of the links. Normal belt-fed have the belted ammunition oriented “brass to grass” with the links on top and the exposed brass facing down. Go back and look at the Colt prototype. It too has the links on top. Not the case with Ciener’s conversion. The links are oriented facing up. By doing this, the links act like the feed lips of a magazine. So the bolt can strip a round from the link like it would from a standard box magazine.

If you remove the feed mech from the converted rifle, it can use standard AR-15 magazines. There will be massive windows on the side of your receivers. But this will not affect function other than letting sand get into the gun easier.

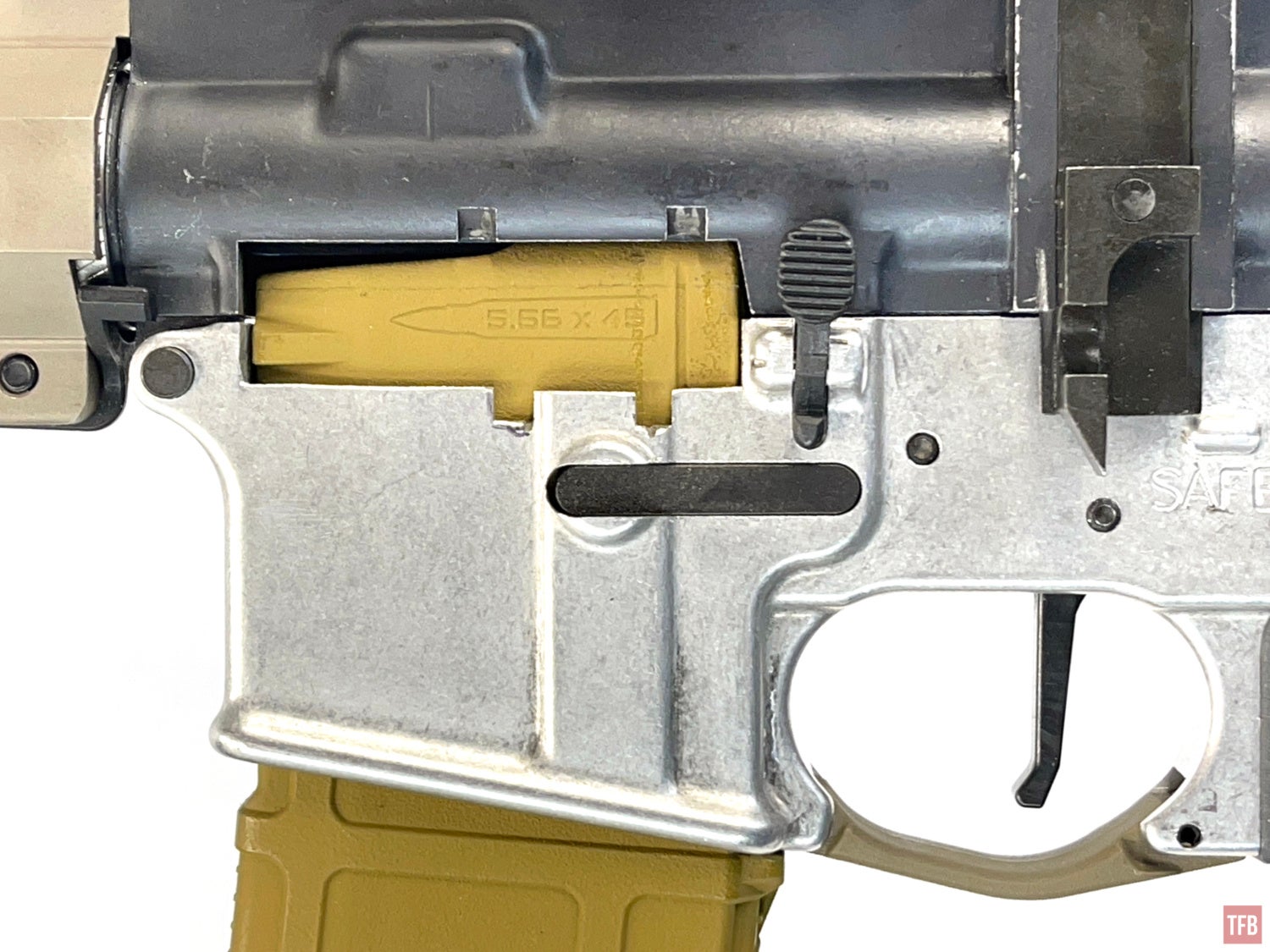

If you have transparent magazines, you can see the last few rounds hidden by the magwell.

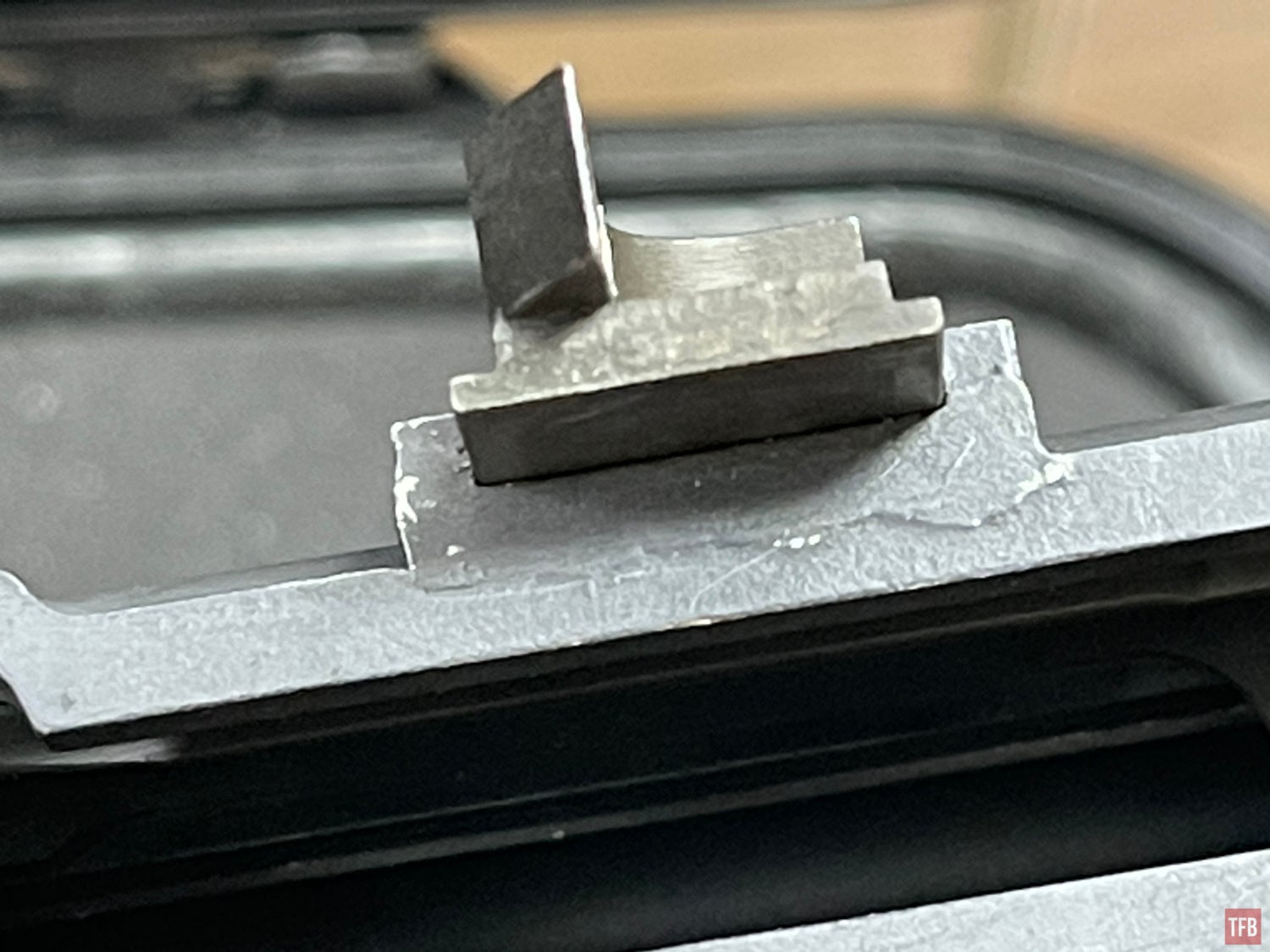

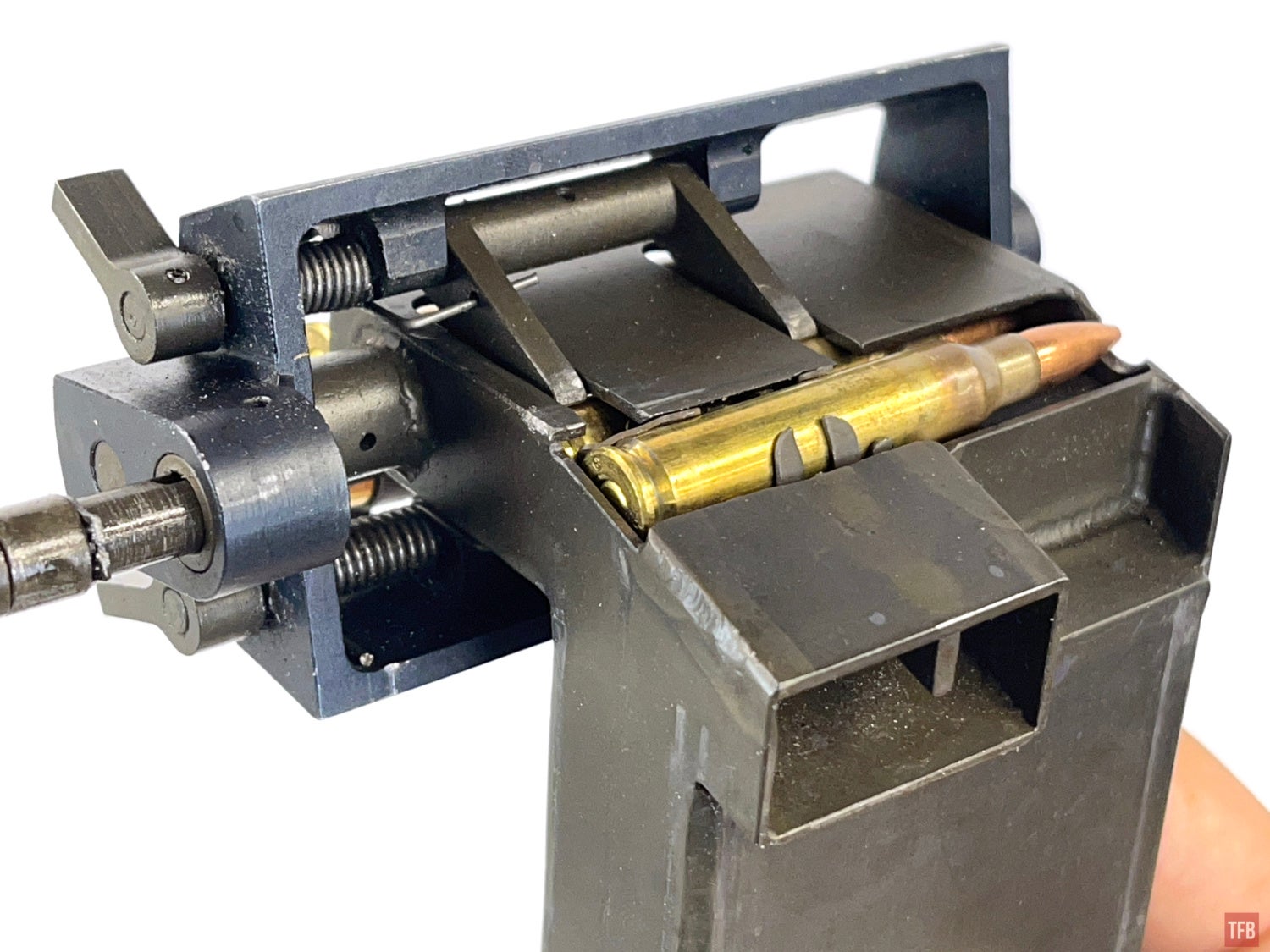

The M27 links are modified with a notch that lines up with a tooth in the link chute. This helps keep the cartridge and links straight as it feeds the gun. This is why it is crucial to use the factory ammo box with the link collection chute.

Here is a round ready to be stripped and chambered by the carrier.

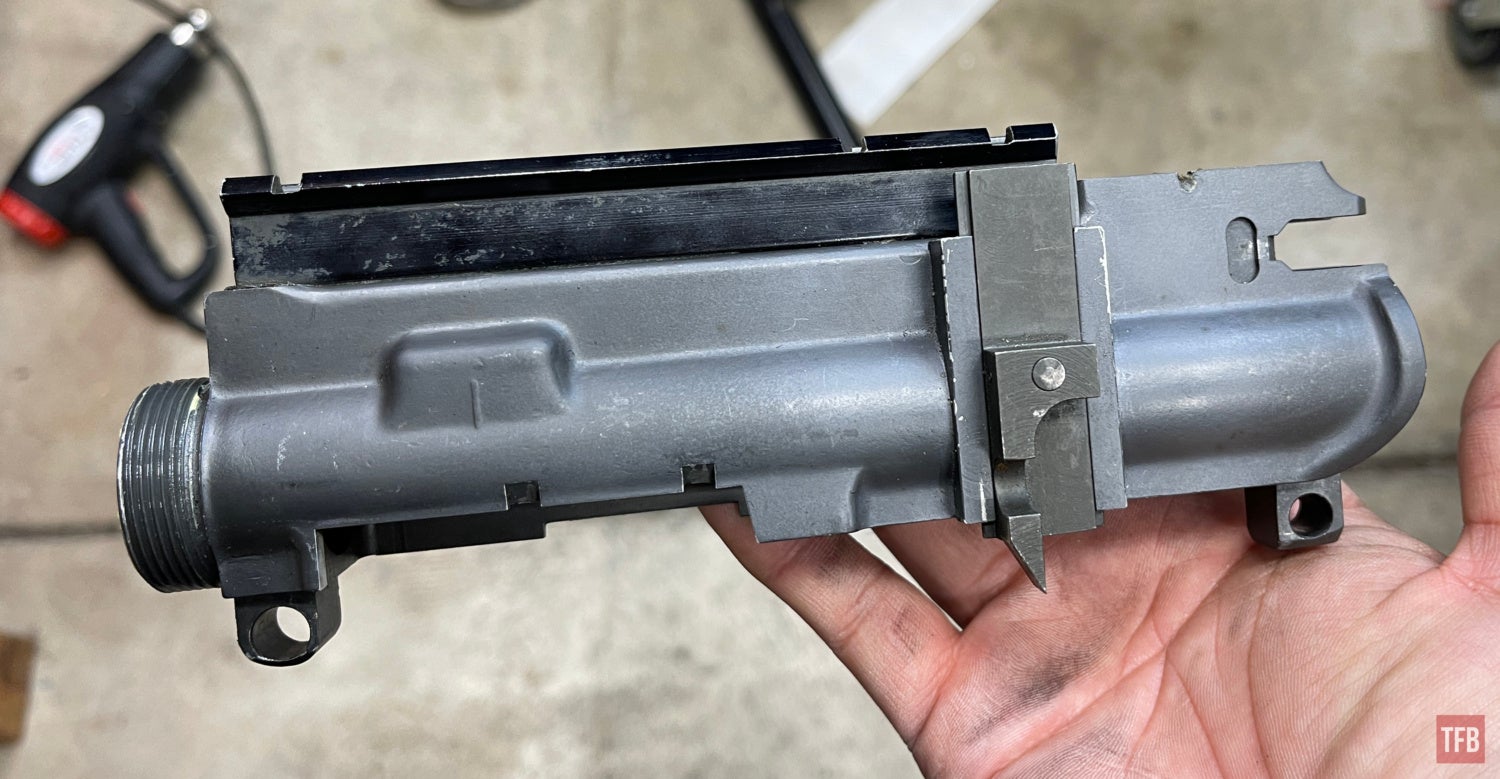

Here is the lower receiver. You can see the modification Ciener made to fit the feed mechanism. Also, he built this on a ban-era Colt Sporter. I strongly dislike John Ciener and Colt for making this abomination, which I will explain later.

My FFL actually had a newer version of this belt-fed AR made by a company called Valkyrie Armament. Allegedly they sold off their designs to SlideFire. But we know what happened to SlideFire. My FFL still has the lower he cut for a post-sample belt-fed.

The cuts are very similar so I tried inserting my Ciener belt-fed feed mech and it fits.

You can see the tooth in the link chute above. Below is how the link interacts with the tooth.

Upgrading The Ciener Belt-Fed

As I said earlier, I despise this Ciener monstrosity because of the gun he built it on. It is a ban-era Colt Sporter. So it has a number of asinine AWB features.

- Large front takedown pin

- Sear block

- Modified trigger to fit sear block

- Neutered bolt carrier

Those are just the standard Colt features they implemented. Sure there are solutions to these problems but the carrier is not so easily fixed. Due to the proprietary drive pin slot down the side of the carrier, I cannot easily replace it.

On top of that this Ciener belt-fed has a free float tube handguard and a weaver rail for optics. Such a strange choice. Granted Picatinny was not an option back in the day but the handguard? It is a solid piece with the barrel nut integrated into it. It is not a simple tube threaded onto the barrel nut. So that was one of the first things to go along with the HBAR barrel. My friend helped me remove the front sight gas block so I could remove the gas tube and spin the tube handguard off.

I installed a carbon fiber wrapped barrel I got from CROM USA. They wanted me to torture test the barrel. I figure a belt-fed would be a grueling test.

Here is the Ciener belt-fed with my friend’s ALG handguard just to see how it looks.

I went with a free-float Midwest Industries rail I had lying around and used a Magpul PRS LITE stock and B5 grip. I also mounted an EOTech 512 up top.

Upgrades Not For The Faint Of Heart

For those of you not familiar with Colt ban-era features, Colt installed something called a sear block into the fire control pocket of the lower receiver. Below is a photo of the sear block.

It sticks up so you can’t use a full auto carrier. Which is dumb since you can’t use a sear anyway.

And then Colt made the sear block protrude downward. See the block highlighted in blue? It occupies space normally for the rear of the trigger. So Colt had to machine away part of the trigger to accommodate the sear block. So that means I cannot use any other trigger. Thanks, Colt, I hate you.

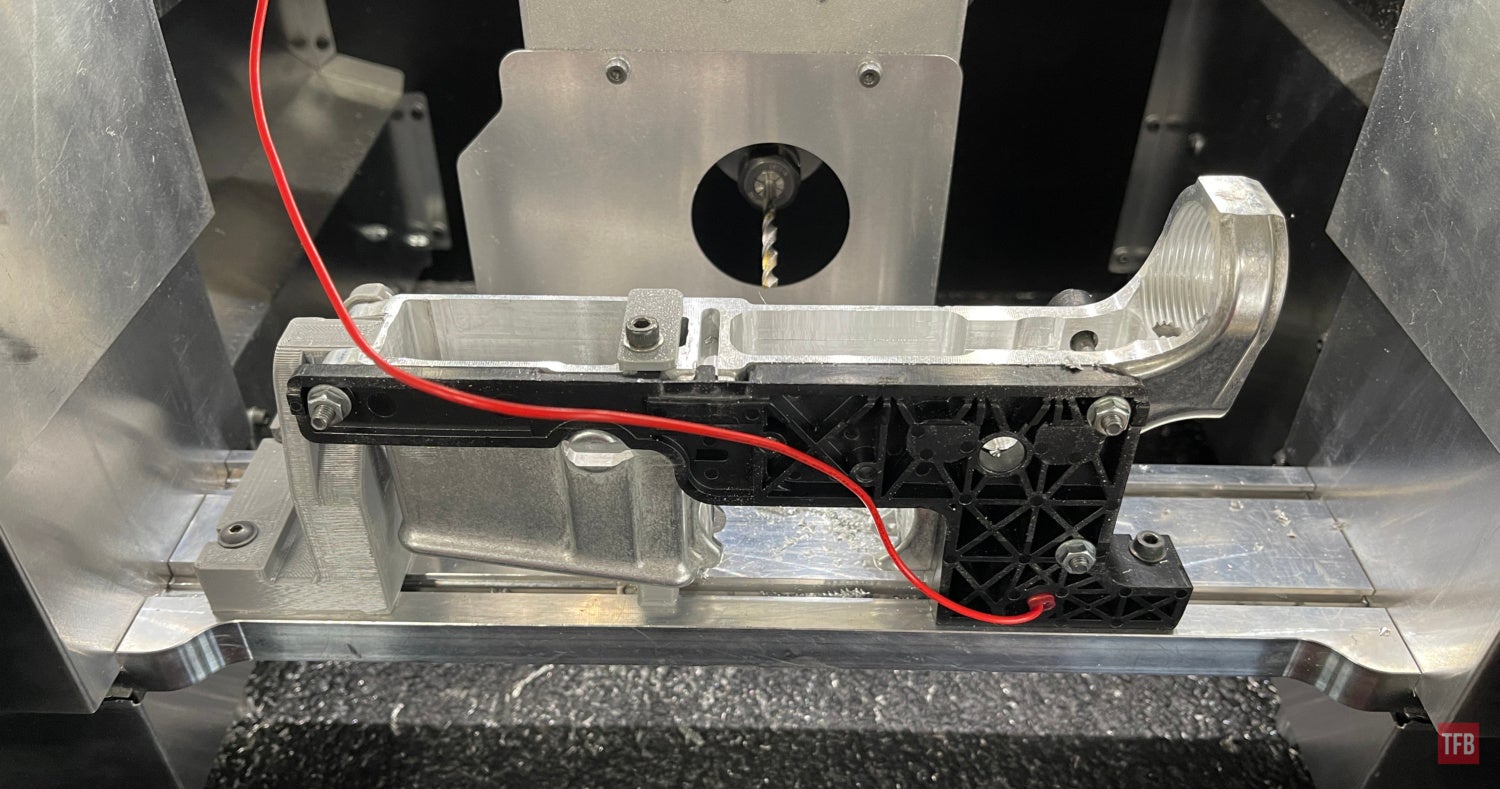

As much as I hate this, I do not want to make any permanent modifications. So I decided to make a new lower out of an 80% and then modify it like the Ciener converted lower. GG3 to the rescue.

I am sure with the right coding I could mill the same cuts as the original lower with the GG3 but for a one-off, a Dremel will work just fine.

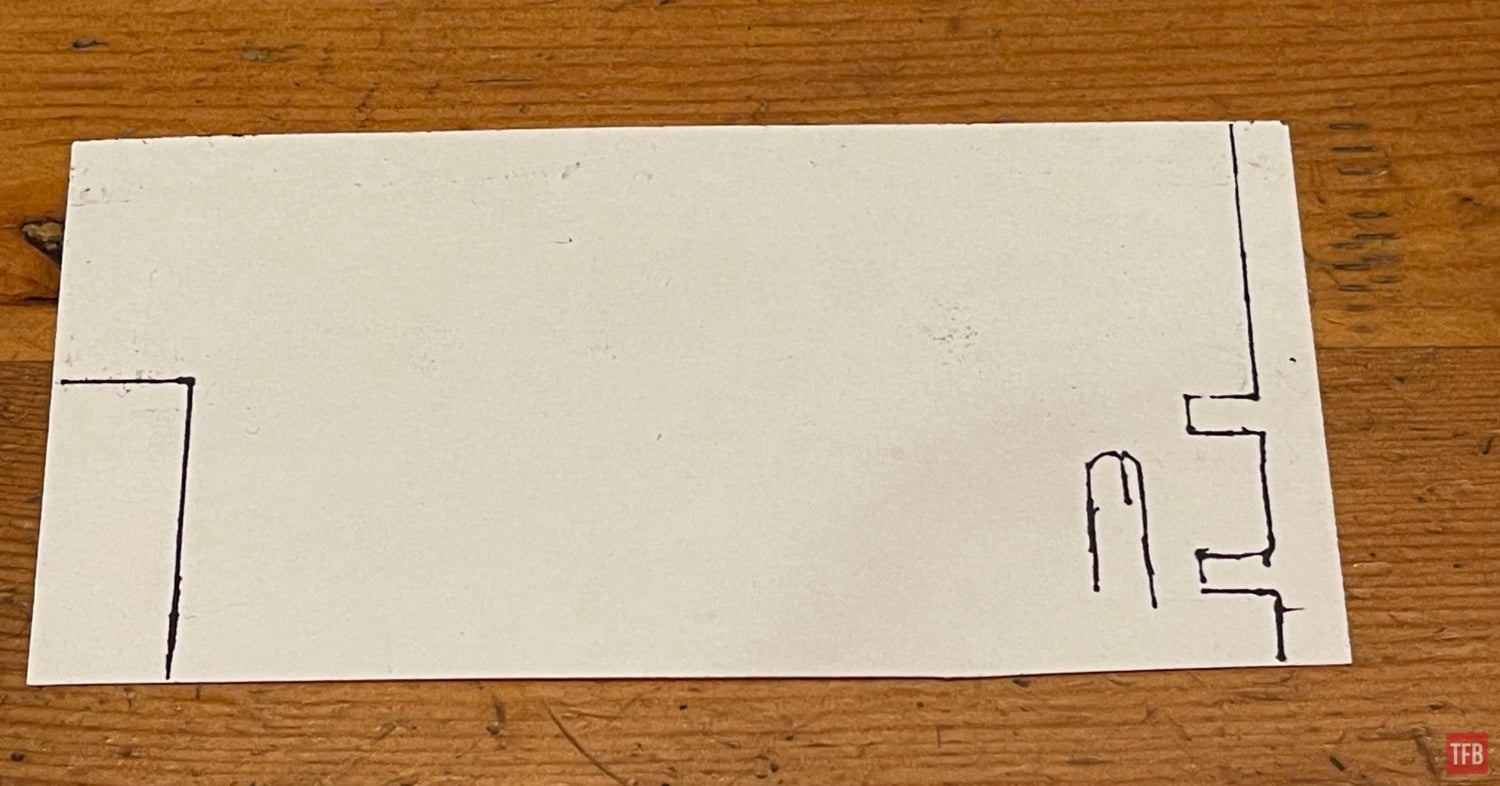

I removed the mag catch on the Colt lower and used a piece of index card to trace the cuts in the lower.

I did it for both sides.

Voila! Now I can use any trigger I want.

I do have the minor inconvenience of a large front takedown pin upper on a small takedown pin lower. Thankfully there is a small takedown pin bushing that you can buy for $3.50 to solve this problem. I got one from JSE Surplus. They have over 3k units in stock.

Photo by JSE Surplus.

Another modification I made was in manipulating the bolt catch. The problem with the Ciener belt-fed design is that the feed mechanism rocks back and forth. The top of the feed mech gets too close to the upper receiver when the bolt is closed but moves away when the bolt cycles to the rear. You could reach in with your finger, with the bolt held open by the charging handle, and press the bolt catch to lock the bolt open. But if you mess this up and release the bolt, the feed mech will close on your finger and it will hurt a lot. There is no room to use a BAD lever so the only option was to use an ambidextrous bolt catch. I have a PDQ on one of my lowers but it is not aesthetically pleasing. Caleb of SilencerCo helped me get the ambidextrous bolt catch used in their SCO-15 lowers. My friend Vic M helped me mill the receiver for the ambidextrous bolt catch. It was a bit beyond my Dremel skills.

When the bolt is pulled back, the feed mech opens up and you can reach in to touch the bolt catch. It is a tight squeeze.

However, once the bolt closes, it drives the feed mech close to the upper receiver. You do not want your fingers between the feed mech and the upper receiver.

The final problem in this story is the bolt carrier itself. Colt neutered this too. The rear tail section is completely milled off and there is an undercut near the back of the firing pin that will cause an M16 hammer to lock up on the carrier.

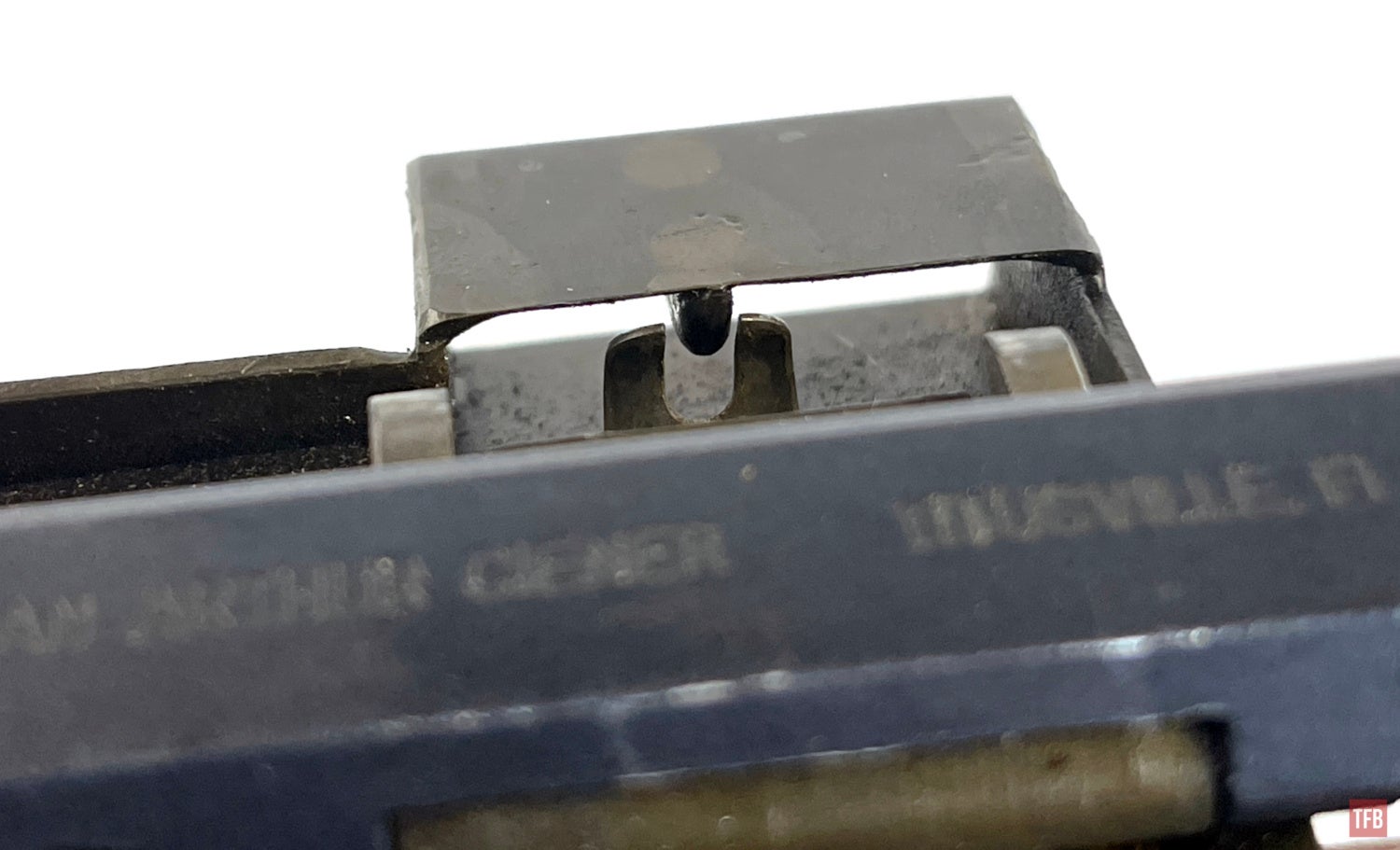

So I reached out to a number of people I knew who machine gun parts. Only BSD Fabworx was willing to modify a normal BCG for me. It took a while as he is busy, about 6 months, but he did it and it was not easy. Remember I mentioned the position of the firing pin retaining cotter pin? Well, I never noticed it before but it is not in the usual position for the Ciener belt-fed conversion carrier. Normally this retaining pin goes from 9 o’clock to 3 o’clock. But this one sits higher up and goes in at an angle. See how close it is to the gas key? It was relocated to clear the drive pin slot just below it.

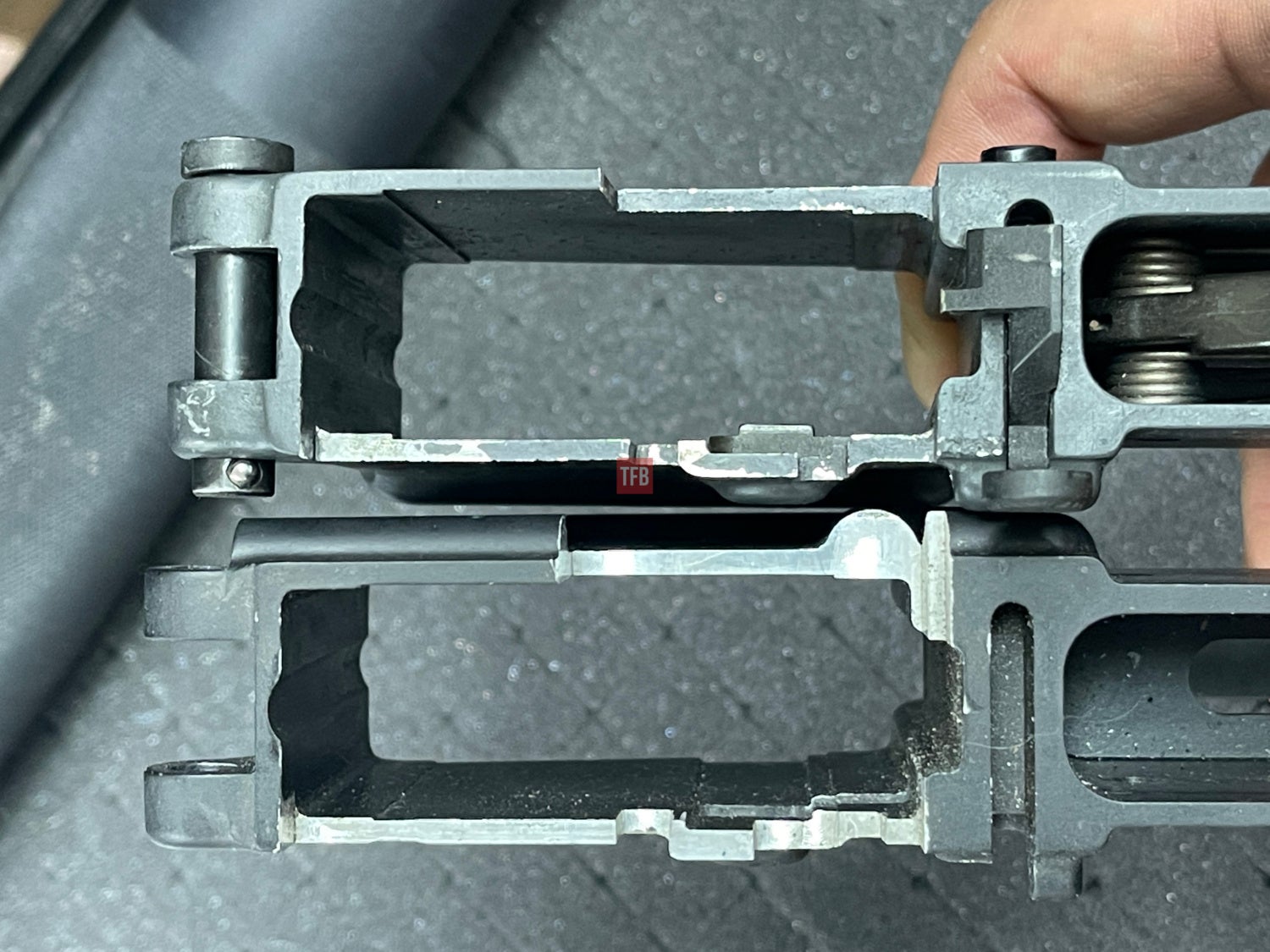

Look at the image below. The carrier on top is the one for the belt-fed. The one below it is a normal carrier. The hole for the retaining pin exits in the middle of the forward assist serrations. While on a normal carrier that hole is just above those serrations. Why is this subtle difference important? BSD Fabworx found out why.

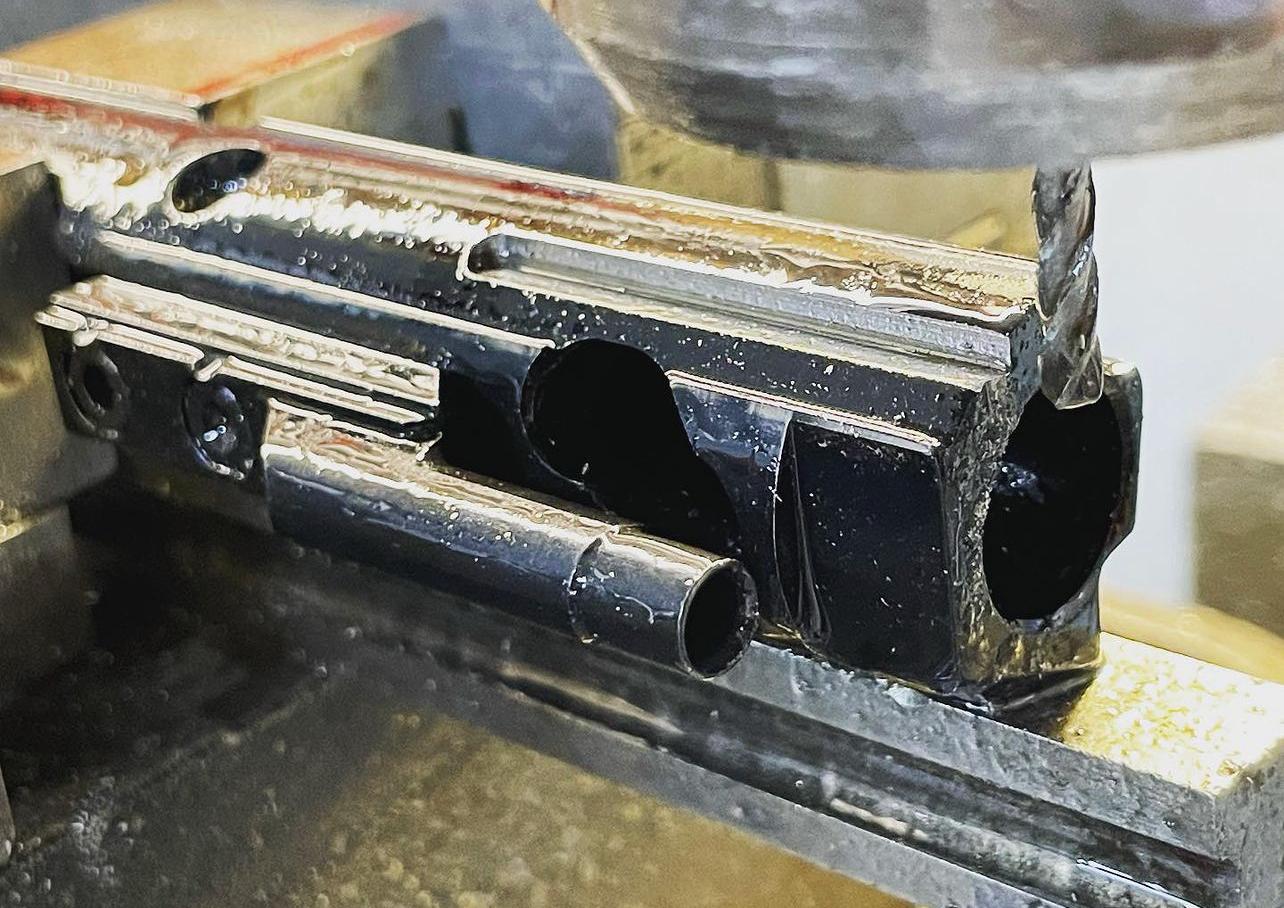

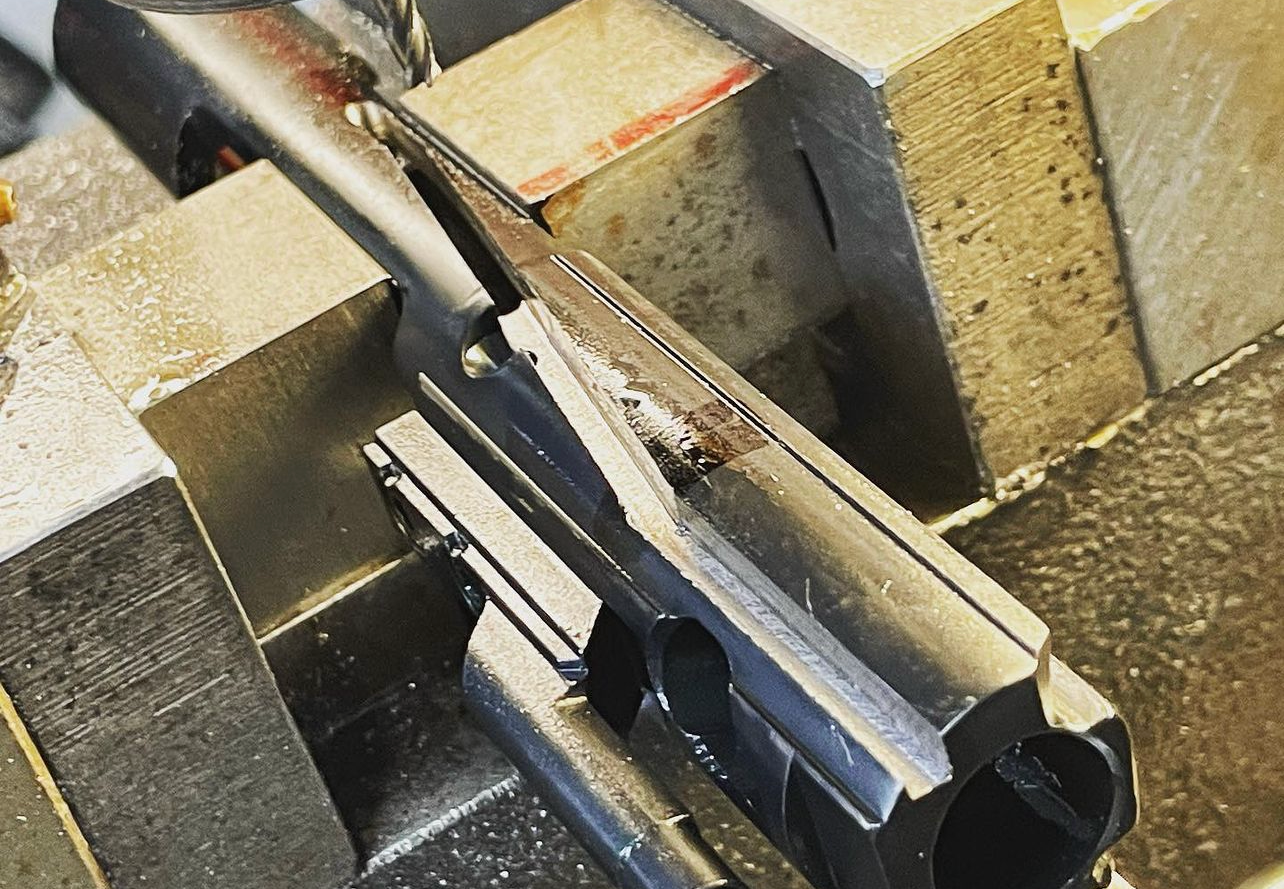

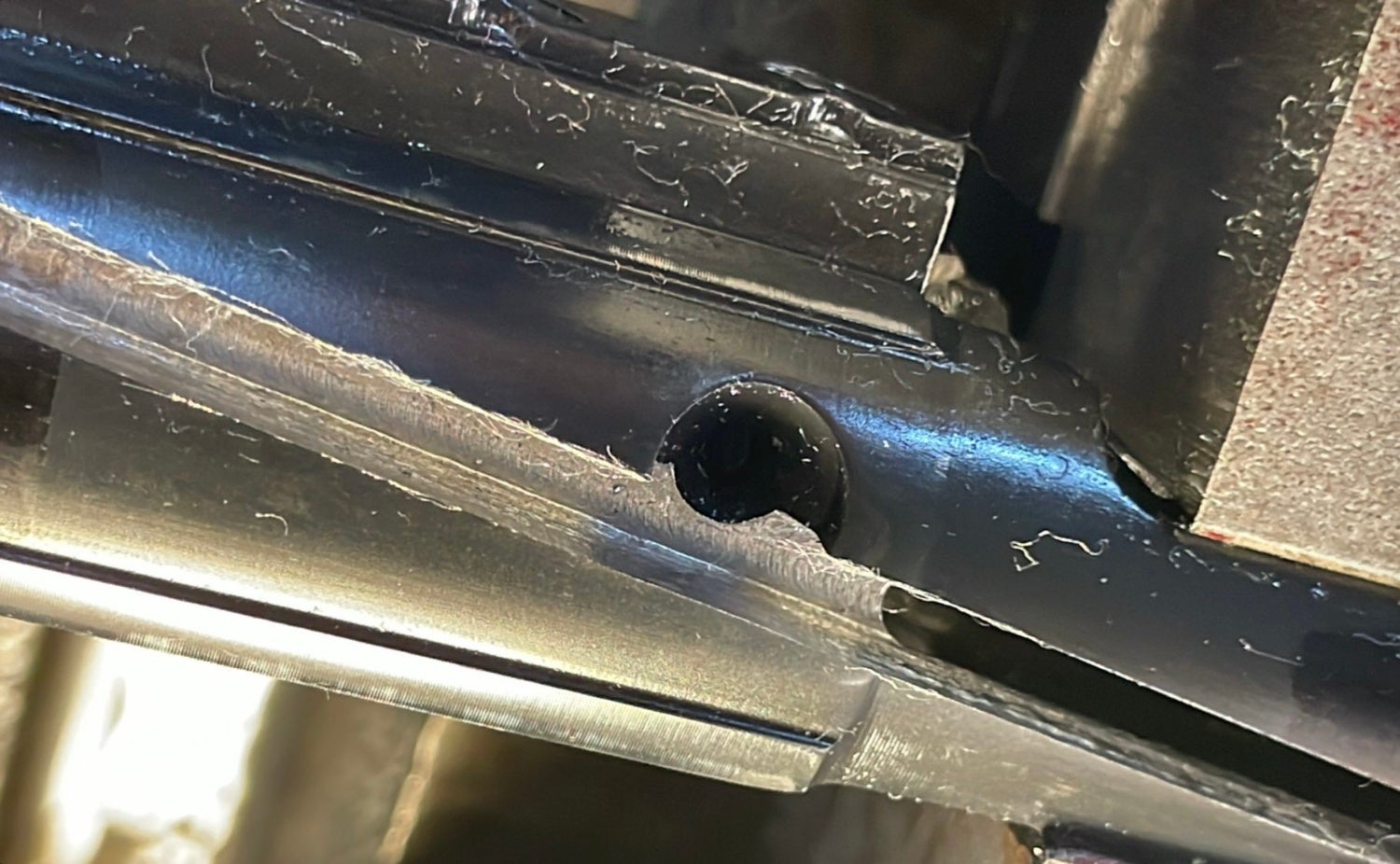

Here are photos BSD posted of the modification they made to the carrier.

The slot for the drive pin cut through the bottom of the retaining pin clearance hole. This is a serious problem. The drive pin could get caught in this and break off.

I got the BCG back and when I tried running it in the Ciener belt-fed it had a number of failures. It did not strip the first round and when it did, it would not seat fully into battery. I tried using my factory Ciener modified carrier in my modified lower receiver and I still had issues. The bolt would lock back when fired. Or when it failed to feed, it would take a lot of effort to pull the bolt back. I will need to revisit the modifications and isolate the problems to solve them.

Final thoughts On The Ciener Belt-Fed

I ran the Ciener Belt-Fed at a local night vision practice. Due to time constraints and the number of participants, I was only able to shoot the stage once. But the Ciener Belt-Fed ran great. I set it up using a Viridian hand stop laser mounted at 6 o’clock, I also added a SureFire vampire on the right side with a Unity Tactical MLOK Hotbutton mounted at 12 o’clock on the handguard. That way my support hand thumb can activate the light while my index finger activates the aiming laser.

I do not know why John Ciener built a belt-fed from a ban-era Colt Sporter. It is truly annoying. I have found two other people who have Ciener Belt-Feds and theirs were built using regular COLT ARs. One of which is a transferrable machine gun.

I bought the Ciener Belt-Fed from Sven of Manticore for $5,000. That is cheaper than a Fightlite MCR upper receiver. Although in hindsight the MCR would be a lot less headache. Next, I plan to swap the barrel out for 16″ .300 Blackout and try shooting .300BLK out of the Ciener Belt-Fed.

Your Privacy Choices

Your Privacy Choices