The U.S. Army Combat Capabilities Development Command’s Army Research Laboratory (CCDC ARL), has developed a novel type of polymer filament. This is said to be capable of offering the performance of injection molded ABS on components printed with low-cost extrusion 3D printers. This advancement may achieve the goal of providing troops with the means of manufacturing, fast and inexpensively, vital parts in the field, instead of waiting for long delivery lead times.

US Army Research Brings Tough Polymer to Low-Cost 3D Printers

Bases of FFF 3D Printing

We’re all familiar with 3D printed components and 3D printing enabled gunsmithing. The latter, with few exceptions, is usually accomplished on inexpensive extrusion 3D printers, employing the process called FFF (Fused Filament Fabrication) or FDM (Fused Deposition Modeling, a trademark owned by Stratasys).

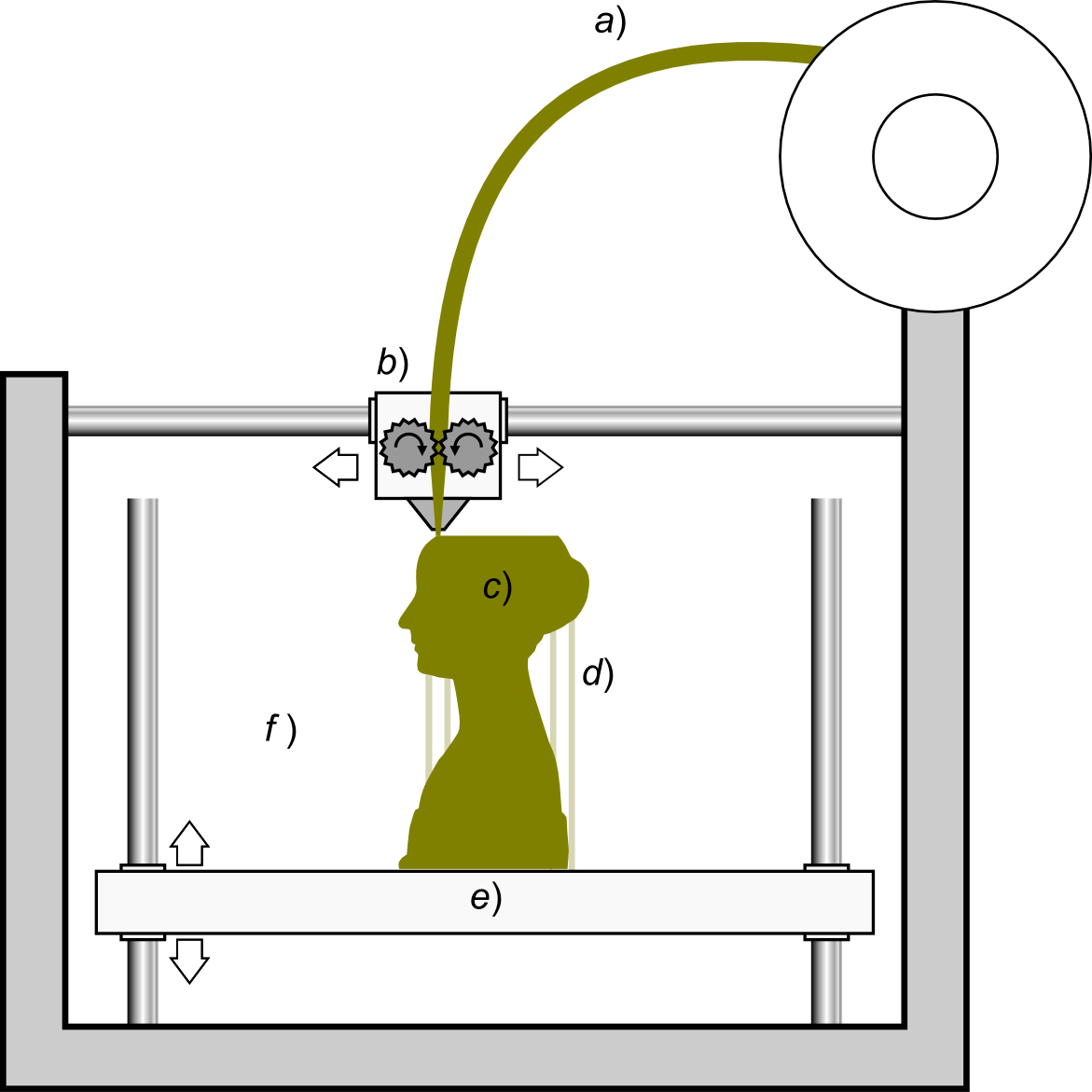

These machines operate by pushing a polymer filament gradually through a heated nozzle, which moves on the XY plane following coordinates provided by G-code and therefore depositing material in a defined pattern, which forms a layer of the final part. An increment on the Z-axis allows the nozzle to print a layer above the previous one, and so on. The resulting object can be very accurate, although, depending on the layer height, the layers along the direction of growth can be visible.

US Army Research Brings Tough Polymer to Low-Cost 3D Printers – FFF schematics (Image Credit: Wikimedia Commons)

There are several materials accessible to hobby-level FFF printers, from the ubiquitous PLA to carbon fiber reinforced Nylons. Moreover, there are many other engineering polymers requiring high-end machines. While we know that 3D printed polymer parts can be fully functional, their mechanical performance, especially toughness, is usually inferior to the one obtainable by conventionally manufactured (i.e. injection molded) objects made with the same material.

Of course, high-end machines and expensive feedstock can allow the printing of parts as good or better than injection molded ones made of cheaper plastic, but this would not be practical nor convenient. So, how can we obtain an ABS 3D printed part as good as an injection-molded one?

Getting performance with low-cost printers

The CCDC ARL tried to tackle the above conundrum, as they aim to offer soldiers in the field the capability of manufacturing spare parts with inexpensive, portable machines. It’s unlikely they are considering firearms parts, probably generic unspecified pieces of equipment that due to wear or failure may require replacement. Moreover, the ability to print on demand would offer the soldiers the opportunity to modify the components to their actual needs.

Instead of looking at exotic materials or proprietary processes, the researchers focused on ways to increase the toughness of parts printed with existing filaments, such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS).

Building on previous researches of Dr. Eric D. Wetzel, leader of the Emerging Composites team, such as these patent applications (US20180087189A1 and US20160281267A1), the ARL scientists developed a way to manufacture a Dual Material filament.

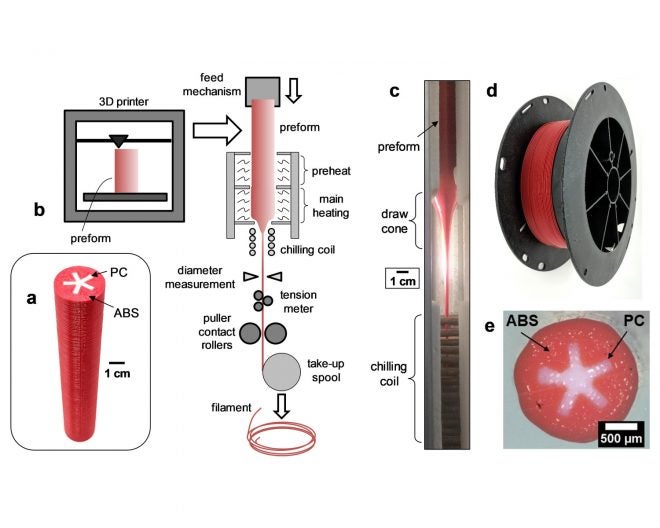

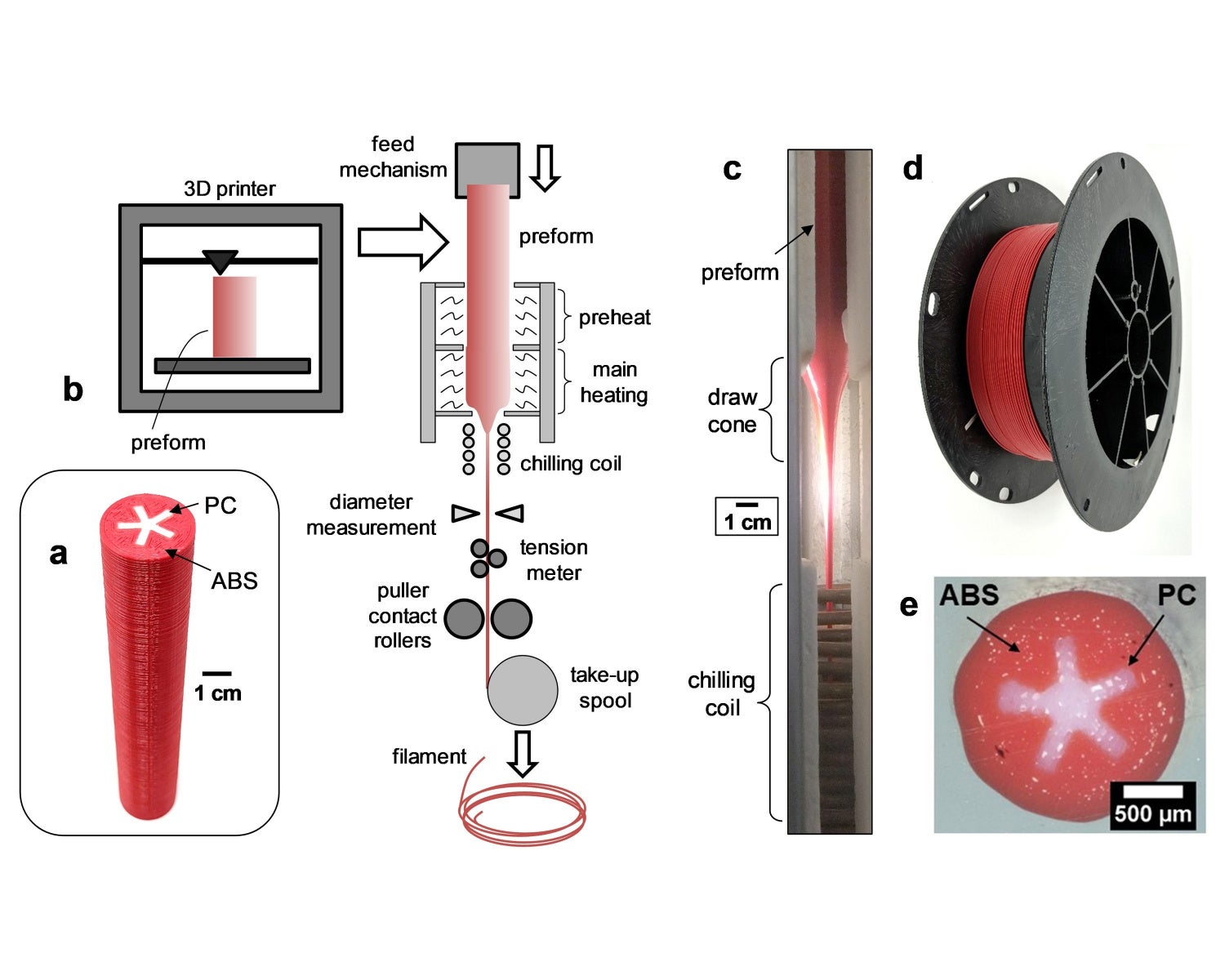

US Army Research Brings Tough Polymer to Low-Cost 3D Printers – The dual-material cylinder, printed (a and b) and drawn into filament (c and d). The section of the filament (e) reflects the original structure. (Image Credit: Hart, K.R., Dunn, R.M. and Wetzel, E.D. (2020), Tough, Additively Manufactured Structures Fabricated with Dual‐Thermoplastic Filaments. Adv. Eng. Mater., 22 – Via: U.S. Army)

In a 3D printing inception, they first 3D printed an ABS cylinder with an asterisk shaped PC core. This cylinder was then brought to its melting point, cooled and drawn into a filament of calibrated diameter compatible with standard printers (either 1.75mm or 2.85 mm).

The dual-material filament maintains the PC skeleton and ABS body of the original cylinder. Parts printed with this feedstock can then be annealed (for 24 to 48 hours) at a temperature sufficient to soften ABS but not PC, therefore the dimensional integrity is not affected.

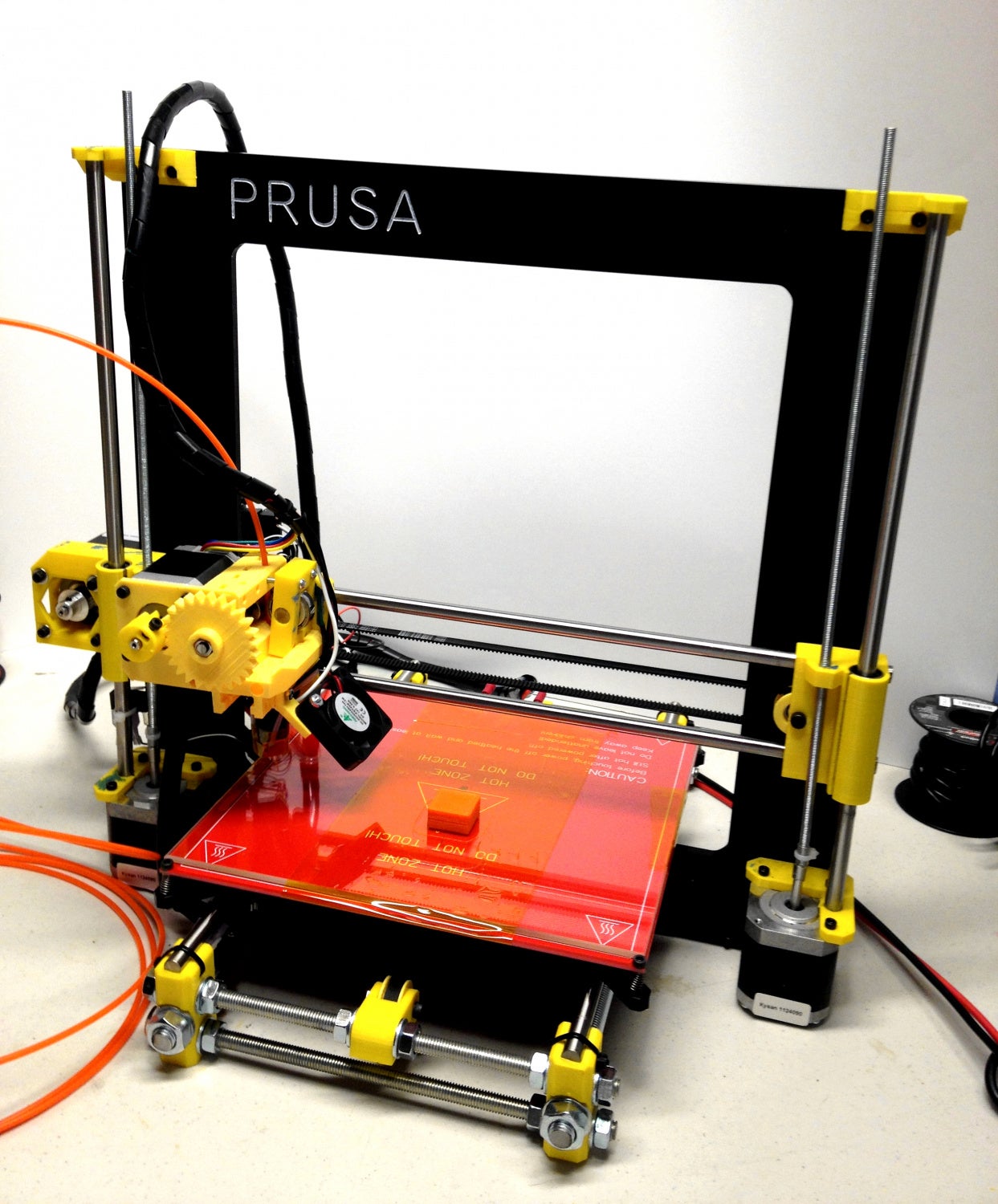

The testing performed by ARL confirms that the process provides a final toughness comparable to injection molded ABS parts. The parameters required for printing this filament should fit within the capability of any higher-end consumer grade 3D printer.

US Army Research Brings Tough Polymer to Low-Cost 3D Printers – An old iteration of a very common consumer 3D printer, capable of printing ABS and, potentially, PC. (Image Credit: Wikimedia Commons)

The next goal of the researchers is to reduce the annealing time to about 8 hours. However they are already in the process of acquiring commercial partners to scale up this technology.

CONCLUSIONs

While it may take some time before we can see some commercial applications of this technology, it’s surely interesting to see such an “out of the box” approach in military development.

When, and if, this type of filament will hit the market, it may not become the first choice of our 3D printing gunsmiths, who seem to prefer the easier to process PLA. However, it can open the market at a relatively simple way of manufacturing replacement parts or new, customizable firearm accessories fully comparable with commercial models.

For those interested in learning more about the research, the peer reviewed paper is published in the April issue of Advanced Engineering Materials (paywall; the supporting information document can be freely downloaded).

Sources:

New Army tech may turn low-cost printers into high-tech producers.

Hart, K.R., Dunn, R.M. and Wetzel, E.D. (2020), Tough, Additively Manufactured Structures Fabricated with Dual‐Thermoplastic Filaments. Adv. Eng. Mater., 22: 1901184. doi:10.1002/adem.201901184

Your Privacy Choices

Your Privacy Choices