Lyman® Products Mark 7 division is set to transform the reloading experience for sport shooters and competitors ready to expand their capabilities. The Mark 7 Evolution is a 10-stage manual loading press that includes many features not normally found with traditional presses and can incorporate options from additional sensors, accessories and an autodrive.

Mark 7 Evolution

As one of the premier reloading specialists, Lyman Product’s continues to bring innovation through new, smarter products that combine the best of technology with superior manufacturing. The acquisition of the Mark 7 line is a clear indicator that Lyman Products is dedicated to its customers and forward-looking in their business practices.

The Mark 7 Evolution is a significant step in providing reloaders, competitive shooters and anyone that wants to spend less time at the bench and more time doing what they love the most, an advanced tool that can evolve through a variety of upgrades for the user.

Mark 7 Evolution

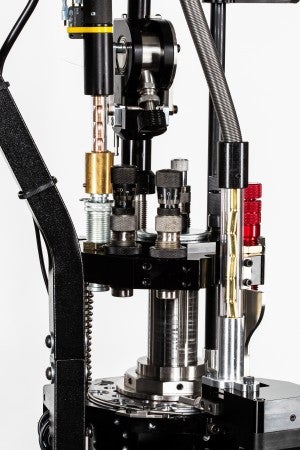

The Evolution is complete with an 11-inch case feeder, a mechanical powder measure, and a standard stacked priming system. It supports calibers from .380 ACP to .30-06 and works on new and used brass. It also supports one-pass rifle/pistol processing and loading. The manual hand-operation is ambidextrous and the handle itself was designed by a medical device engineer for an ergonomic hold and a smooth press operation. The Evolution is manufactured from CNC machined aluminum and steel for consistent and precise loading every time.

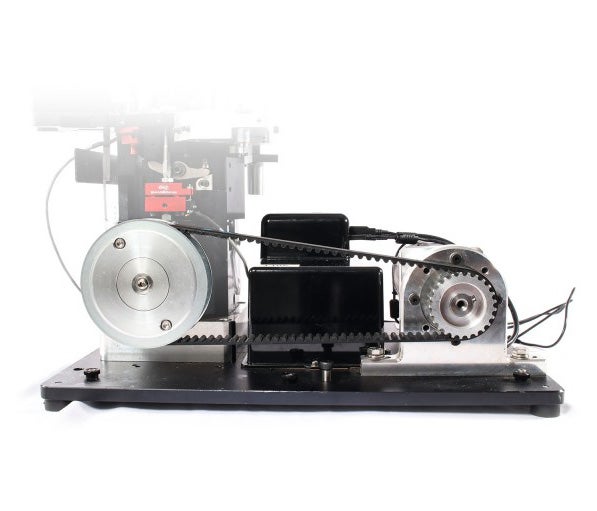

Mark 7 Evolution – Autodrive attachment

What sets the Evolution apart from other loading machines is the ability to add on options and sensors and even an autodrive to increase the capabilities of this unique loading machine. The Mark 7 Evolution Autodrive increases bullet production for up to 3,500 rounds an hour* by automating the Evolution manual press. It comes with a 10-inch high definition tablet and mount and JamSense and TorqueSense sensor ware.

It features a 1.5 high torque motor, a maintenance-free timing belt drive and a CNC grade planetary gearbox. It is microprocessor controlled with a digital clutch making it adjustable on the fly and a digital job and immediate stop. All the features are monitored through a computer with a life-time of downloadable software upgrades.

Mark 7 Evolution

Optional sensors are also available including a Wired Remote Stop, DecapSense, SwageSense, PrimerSense, PowderCheck, BulletSense, and a Primer Orientation Sensor.

Lyman Products’ Mark 7 Evolution 10-stage Manual Loading machine is $2,995.00 and the Mark 7 Evolution Autodrive is $1,994.95. Optional sensors start at $199.95.

*Speeds vary based on machine settings.

Your Privacy Choices

Your Privacy Choices