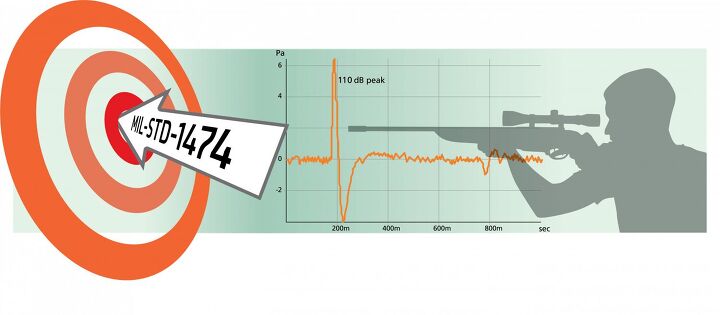

When it comes to sound level testing for gunshots, there is only one real set of criteria that matters: MILSTD Acoustic Noise Limits. Specifically the MIL-1474D and MIL-1474E standards. If you’re a suppressor/silencer nerd like myself, the MILSTD testing criteria probably needs no explanation. For the rest of you, the MIL-1474 outlines the protocols, procedures and equipment required to accurately measure the sound of a gunshot.

In a nutshell, consumer-level decibel meters are just not capable of the sampling rates needed to accurately capture the sound of a gunshot. In fact, the data collected with substandard equipment is worse than having no data at all. Luckily Brüel & Kjær has introduced the Impulse Noise System which is a portable, battery-driven decibel meter that exceeds military standards for testing gunshots.

New MILSTD B&K Impulse Noise System Exceeds Military Requirements

I’ve expounded on the MILSTD testing requirements at length in the past and believe that the B&K Impulse Noise System is as good as it gets for properly field testing suppressed gunshots. Details can be found below.

New MILSTD B&K Impulse Noise System Exceeds Military Requirements

New Impulse noise system’s higher sampling rate meets military standard for noise limit measurements

USA, September 2019

Brüel & Kjær (www.bksv.com; who, along with HBM, Inc. (www.hbm.com), comprise Hottinger, Brüel & Kjær (HBK), has introduced a portable, battery-driven system for measuring and reporting the impulse noise produced by unsuppressed and suppressed firearms.

The system provides high accuracy measurements of impulse noise peak values to support comparing and evaluating various prototypes for their potential for causing hearing damage. The MIL-1474 D and MIL-1474-E standards establish acoustic noise limits and prescribe testing requirements and measurement procedures for determining conformance to the noise limits. In contrast with other sound level measurement systems currently on the market, the Impulse Noise System’s high-accuracy LAN-XI data acquisition hardware complies with these standards with a sampling rate of 262,144 samples per second. The most current version of the standard calls for a sampling rate of at least 192,000 samples per second.

Unlike earlier analog sound level meters that required pressing a button to reset them after each test shot, Impulse Noise System can acquire, record and display the results of multiple shots automatically.

The Impulse Noise System solution is optimized for the testing requirements of manufacturers of small arms, suppressors, ammunition, muzzle brakes/compensators, hearing protection products, and air guns, as well as military and law enforcement bodies. The system bundles sensors, data acquisition hardware and system software into a comprehensive measurement and reporting solution at an economical package price.

In introducing the system, Jens Hansen, the business development manager at Brüel & Kjær Sound & Vibration Measurement, explained, “The Impulse Noise System combines the highest accuracy impulse noise measurements on the market today for evaluating small firearms with high testing throughput. It’s well-suited for use in remote test environments like firing ranges because it offers a battery-driven design, easy system setup and operation, and minimal cabling. The hardware, software and sensors are compatible with both the two most recent versions of the MIL-STD-1474 standard and general benchmarking.”

This system includes all the hardware and software needed for the entire evaluation, from data acquisition with best-in-class hardware to processing and reporting with Type 7963 PULSE Impulse Noise Evaluation software capabilities.

For more information on the Impulse Noise System, visit: https://content.bksv.com/impulsenoise

About Brüel & Kjær Sound & Vibration

Brüel & Kjær focuses on sound and vibration solutions and develops advanced technology for measuring and managing sound and vibration. As a specialist in this domain, the company helps customers ensure component quality, enhance product performance and monitor operational compliance.

For more than 75 years, Brüel & Kjær’s research and development people have excelled and many have become recognized global experts, who aid the scientific community and teach at renowned centres. The application of experience and technology promotes quality and efficiency at every stage of a product’s life cycle: design, development, manufacture, deployment and operation. Mastering sound and vibration is a key component in accelerating business growth and improving environmental quality.

For more information, please visit www.bksv.com

Your Privacy Choices

Your Privacy Choices