Back in March 2017, I reported on a proof of concept attempt to create rifling grooves, essential to ensure stabilization of bullet, in a length of steel tubing using a process known as Electrochemical Machining (ECM). This was achieved using a simple jig designed using a 3D printer combined with copper wire laid into the ‘mirrored’ groove channels through which salt water is continuously passed through using an inexpensive electric pump and bucket set up. Essentially this process is the reverse of electroplating, instead eroding away an exposed surface, in this case, a series of shallow channels usually produced using a rifling cutting tool or by having a ‘button’ forced through.

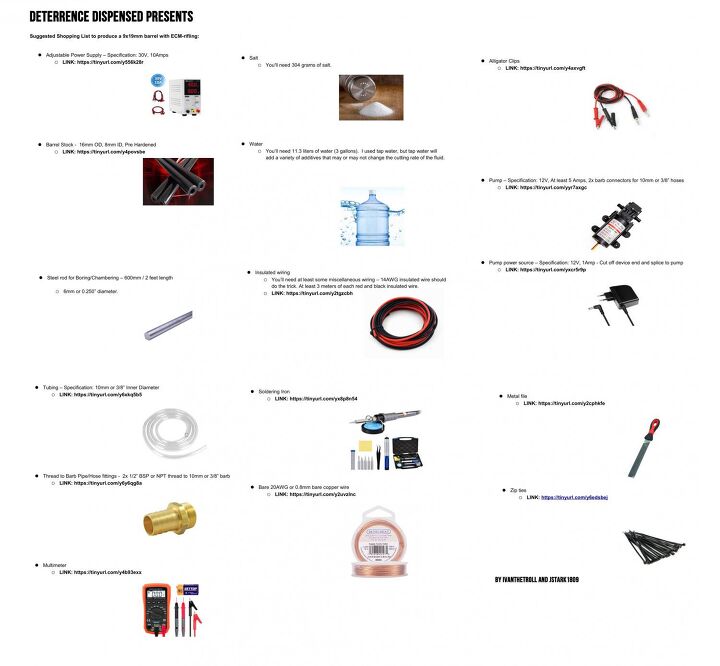

Fast-forward to 2019 and a decentralized collective of gun designers operating under the group name ‘Deterrence Dispensed’ have perfected a method of producing DIY 9mm barrels which not only match but potentially can exceed the quality and performance of many professional factory produced barrels. The best thing about this method is that this allows you to produce barrels without needing a workshop and can even be made quietly in the comfort of one’s cozy apartment. Along with a $200 Ender 3 3D printer, parts for this setup cost less than $100 and the process of making each barrel takes less than 30 minutes to complete. The tubing used to make the barrels can be ordered from Aliexpress and is supplied pre-hardened. Unlike challenges with traditional rifling methods, the ECM process is unaffected by the hardness of a material and can be used on any type of steel without needing to anneal or re-harden.

IvanTheTroll, who has previously been the subject of attacks by New Jersey Senator Bob Menendez for his CAD models, spearheaded the project.

This project pays homage to Jeffrod’s L12k project to use ECM to rifle barrels on a dirt cheap setup. I wanted to standardize the process and get it as cheap as possible. My process and shopping list ring in at under 100 bucks, assuming you have access to a 3d printer. If you don’t have a printer, a 200 dollar Creality Ender 3 will work. This project was named “ButWhatAbout: Barrels”, as a sort of middle finger to the brainlets who felt the need to ask “But what about the barrel? How are you printing that?” when they saw the printed Glock frame CAD release. It’s not a printed Glock barrel, but it is a barrel made by 3d printing plus ECM.

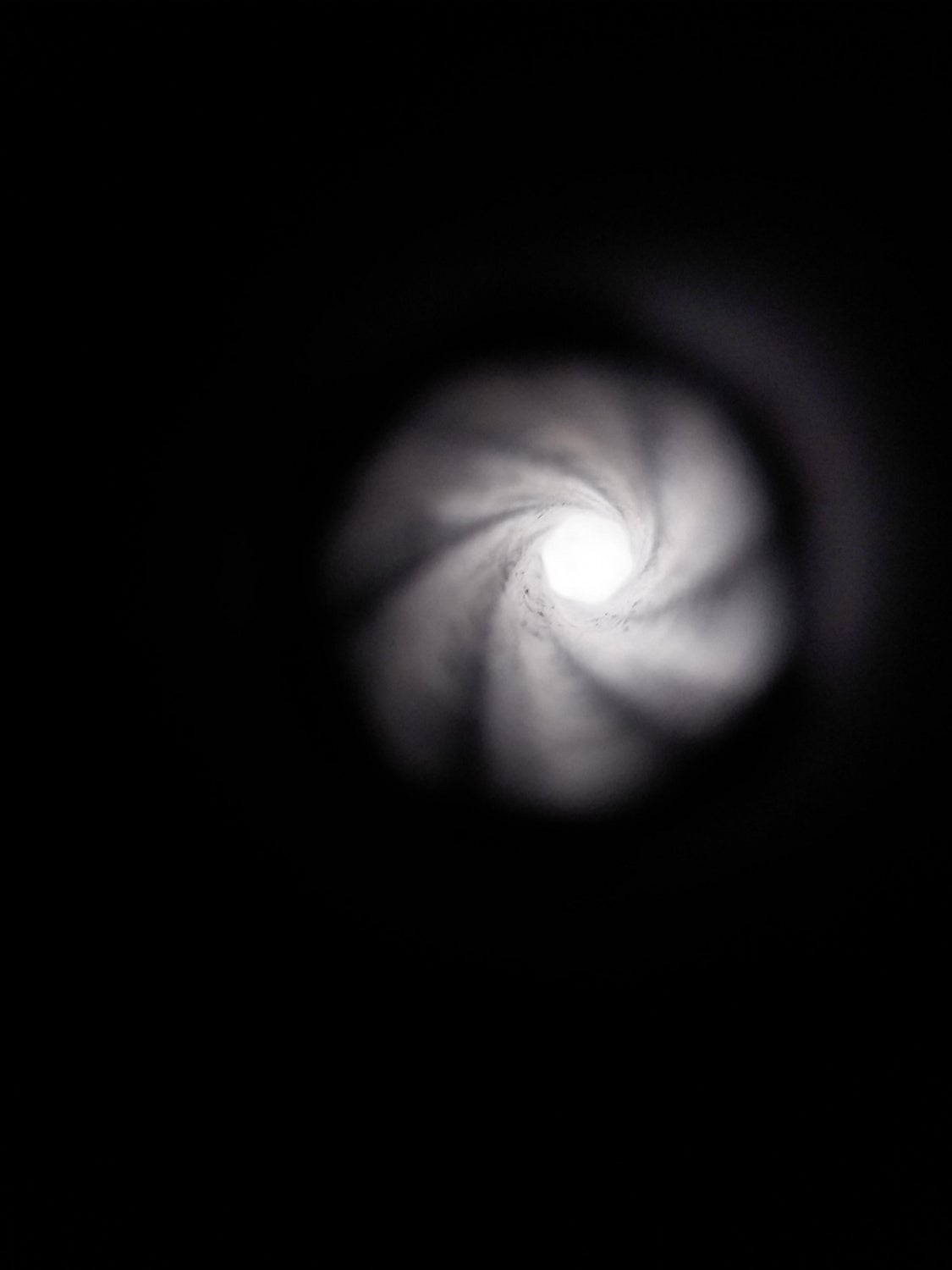

The testbench with barrel mounted. 75 rounds and counting through this setup. It has achieved 2.5in groups at 25 yards, with no signs of tumbling or unstable flight. You can ring steel at 100 yards consistently once it’s screwed down to a shooting bench. Note the hexagonal muzzle crown – ECM is capable of doing polygonal rifling.

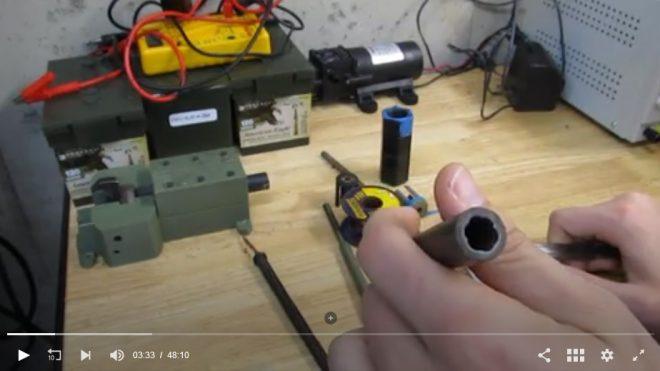

The tool used to rifle the barrel. 3d printed mandrel with copper wire wrapped in the grooves to act as an electrode.

Boring setup. Since the barrel stock is 8mm inside diameter off the shelf, you need to bore it to 8.8mm. I used a center piloted .250 steel rod for this.

Best pic of the rifling I’ve got. This was around 50 rounds down the barrel. There are a couple burrs in the grooves, but they don’t seem to hurt accuracy at all. This view is from the chamber end, you can see the chamber seat close to the camera.

Ivan has since reported that one of the barrels has been fired 123 times without any visible wear or affect to accuracy, A full photo log showing the first barrel being made can be viewed here.

“You may not like it, but this is what peak barrel manufacturing looks like”

A video explaining the entire process can be be viewed here:

A full materials list can be viewed here.

A list of materials used for producing DIY ECM barrels.

As part of the project ‘ButWhatAbout’, the barrel will eventually feature in a mostly 3D printed 9mm semi-automatic carbine, aptly christened the FGC9 (Which stands for F**** Gun Control, 9mm). The FGC9 is an improved version of the Shuty AP9, a 9mm semi-automatic pistol which has demonstrated successfully firing multiple magazines flawlessly in various videos published by its creator Derwoodvw. Whereas the original Shuty design required the builder to obtain a Glock barrel, not something readily available outside the US, the FCG9 makes use of both Ivan’s DIY barrel design as well as 3D printed G17 magazines.

The FGC 9mm semi-automatic carbine (JStark1809)

Your Privacy Choices

Your Privacy Choices