Welcome back my quiet-time friends and thanks for reading TFB’s Silencer Saturday. My name is Pete and I’ll be your host for today’s show. Before we start talking metering and decibels, I’d like to start by asking for some help from you, our readers and fellow shooters. The five questions posted at the end of this week’s edition will start to help me understand your interests a bit better and help me better tailor Silencer Saturday’s future topics. In return, I’ll announce a giveaway in next week’s post. (It’s a surprise, so don’t ask). Obviously participation is completely voluntary. And now, A Tale Of Two Barrels.

Above: The Sig Sauer Rattler In 300BLK and Sig SRD762 QD from Silencer Shop.

Decibel Metering:

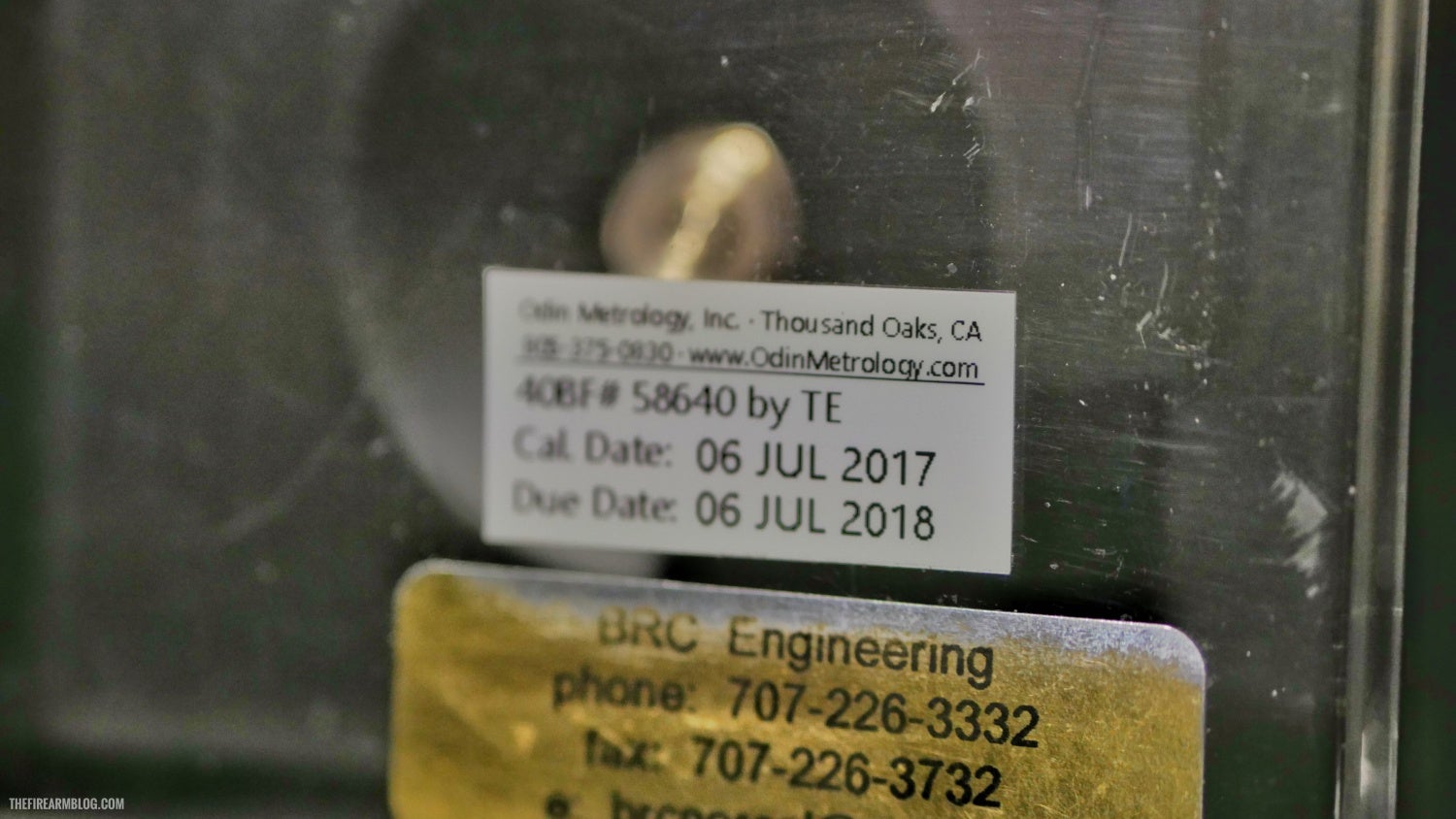

As I discussed a few months ago, Ron at Allen Engineering were nice enough to loan me a proper decibel meter for testing different host/silencer combinations. Specifically, the unit is a B&K 2209, widely accepted by professionals as being one of only a few decibel meters capable of accurately measuring the sound impulse of gunshots. The units are decades old and I believe out of production, but with proper calibration and care, still perform the tasks with scientific accuracy.

Like most testing, the devil is in the details, so to the best of my abilities, I used parts of the MIL-STD-1474D Department Of Defense Noise Limits Design Criteria Standard. This 100+ page document outlines sound level testing for many types of occupational requirements for DOD personnel. The section we will focus on is Requirement 4 – Impulse Noise In Occupied Areas. Without getting too detailed, this section outlines the basics for properly measuring impulse noises (such as gunshots). Besides noting environmental variables like temperature and humidity, the requirements outline meter placement, muzzle placement and other factors that will be a factor in proper metering.

A few caveats:

- I consider myself a “reasonably knowledgeable person” not a silencer expert. Observations provided here are just that, my observations.

- Decibel meter numbers are only a small piece of the equation when evaluating suppressors and host firearms.

- I tried to limit the number of variables as much as possible, but some differences in setups remain.

Let’s take a look at the meter setup.

The CAL200 is used to calibrate the B&K 2209 meter before each test. It will emit two different noise levels and has been certified by a scientific laboratory. On the 114 dB setting, this meter displayed 113.9 dB.

Lab calibration certification of the B&K 2209 is good for another month.

The microphone is very fragile and should not be touched or cleaned with anything that will leave fibers or debris.

The microphone is also certified by a scientific laboratory.

The B&K2209 is a heavy beast. A strong tripod is a must.

The large dial at the top of the meter is used to place the unit in a 10 dB range for the platform you are testing. For example, rimfire testing would most likely use the 110 dB range while centerfire rifle would use the 130 dB or 140 dB range.

The smaller dial below the meter’s display is used to change the mode of testing. For example, a machine with a continuous noise emission would use a setting that would allow the meter to capture data as it moves up and down over the course of seconds or minutes. For firearms, the Impulse/Hold setting is used to capture the fast noise reading and pin the meter for a dB reading to be recorded in a log book.

SILENCER SATURDAY: A TALE OF TWO BARRELS

Our friends at Dynamic Defense Development loaned us one of their 12” Mid-Length gas “Sierra” barrels with the specific purpose of comparing differences between it and a MK18 10.3” carbine-length 5.56mm barrel when suppressed.

Lets take a look at the specifications:

https://dynamicdefensedevelopment.com/product/sierra/

- Barrel Length: 12″ (measured from bolt face)

- Caliber: .223 Wylde

- Gas System: Mid-Length

- Material: 41v50

- Twist Rate: 1:8

- Treatment: Melonite

- Precision M4 Extension

- 0.625″ Gas Block Size

- Dimpled for Gas Block

- Weight: 1lb 3oz

- .078” gas port size

- BCM gas block (my addition)

Daniel Defense MK18:

- Caliber: 5.56mm NATO

- Barrel Length: 10.3″

- Manuf. Process: Cold Hammer Forged

- Twist Rate: 1:7

- Muzzle Thread: 1⁄2×28 TPI (Threads Per Inch)

- Material: Chrome Moly Vanadium

- Outside Finish: Mil-Spec Heavy Phosphate

- Inside Finish: Chrome

- Gas System: Carbine Length

- Diameter At Gas Port: .750″

- Barrel Extension: A4

- Profile: Government

- Weight: 1.15 lb

- .081 gas port size

- MicroMOA Adjustable Gas Block (my addition – set to full open setting)

Rifle/Lower Specifications:

- H2 Buffer with Milspec Spring

Ammunition:

I used three types of ammo for the testing:

- 62gr Federal Fusion SP

- 75gr 5.56mm Hornady TAP OTM

- XM855 LC 62gr Green Tip

Silencer:

- Manufacturer: Form 1

- Caliber: 5.56mm

- Length: 7.5”

- Outer Diameter: 2.0”

- Material: Titanium

Why a Form 1 suppressor and not a commercial build? Because I didn’t want people focusing on the silencer and not the barrel. Plus it eliminates positive or negative bias against certain brands.

Top: The Sig Sauer Rattler with a Sig SRD762 from Silencer Shop also got metered today. Next week…

Observations: Dynamic Defense Sierra

Federal Fusion – 64 degrees; 60% humidity

- 140

- 138.1

- 137.9

- 138.3

- 136.9

- 136

- 136.6

- 136.5

- 137 (bolt lock back)

- 139 (mag change)

- 137.4

- 137

75gr TAP – 84 degrees; 40% humidity

- 137.8

- 137.1

- 134.1

- 135.1

- 136.3

XM855 – 84 degrees; 40% humidity

- 140+

- 138.6

- 135.6

- 137.1

- 136.3

- 137.

- 134.5

- 137.4

- 136.3

- 135.0 (bolt lock)

Observations – MK18 10.3”

Federal Fusion – 64 degrees; 60% humidity

- 144

- 144.2

- 144.

- 144.5

- 144.4

- 144.1

- 144.2

- 144.4

- 144.3

- 145.2

75gr TAP – 84 degrees; 40% humidity

- 140+

- 146.1

- 147.0

- 146.5

- 146.0

- 146.3

XM855 – 84 degrees; 40% humidity

- 146.1

- 146

- 146.2

- 145.6

- 146.6

- 145.5

- 145.7

- 146.5

- 145.7

- 146.3

Possible Variations:

I was metering alone, so my muzzle placement may have deviated slightly between shots (+/- less than an inch). The Dynamic Defense build did not have a forward assist installed. This could have caused more gas to escape out the rear of the receiver versus the 10.3” setup.

Conclusions:

From the recorded data, the Dynamic Defense 12” barrel metered significantly lower than the MK18 10.3” barrel. Obviously, nearly two extra inches of barrel will allow for extra powder burn. And the mid-length gas system will open the action later than the carbine-length MK18. But if the data is correct, using the Dynamic Defense Sierra 12” barrel over a MK18 10.3” barrel brings shooting full powered .223/5.56mm down below the 140 dB “hearing safe” level – with a 7.5”x2” silencer.

A more comprehensive test would include several 12” mid-length barrels and compare all the dB numbers between manufacturers – maybe six or eight barrels instead of just two barrels.

Stay tuned for more metering results next week. Be safe everyone.

Hi-Power Threaded Barrel from Lone Wolf! Suppress that BHP.

Rugged Testing: Razor vs. Micro30. A SURPRISING RESULT?

Your Privacy Choices

Your Privacy Choices