When shopping for BCG’s for an AR 15 build there are many who are of the opinion there’s not much difference between them other than price. If you do your homework you’ll find there aren’t that many companies making complete bolt carrier groups or the bolts themselves. The majority of companies selling AR’s purchase these parts from companies specializing in the manufacture of BCG’s and other AR parts.

The vast majority produces these BCG’s in the same manner. Using standard machinery the carriers are made then sent off for heat treatment. On return these companies have people trained to do handwork in order to get the bolt carrier and bolt back into spec. For instance the collar on the bolt itself is very critical in proper operation of the entire unit. This collar has to be hand turned to return it to spec. A lot of handwork means more time, which translates to a higher price depending on the purchasing, companies’ requirements and materials used. Extra units are made to compensate for those found to be defective. Most medium priced AR’s use BCG’s made in this manner.

I was looking for something better and found it in the American Built Arms BCG and the bolt itself. This company is veteran owned and they are very particular in the products they sell.

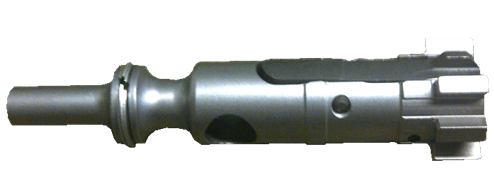

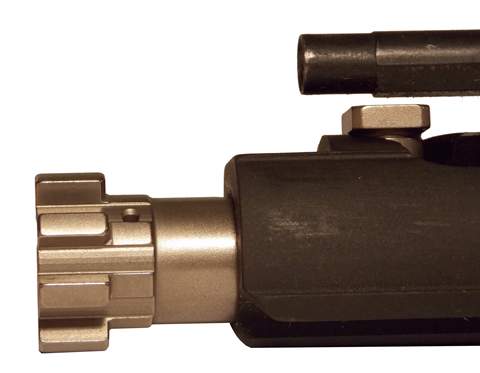

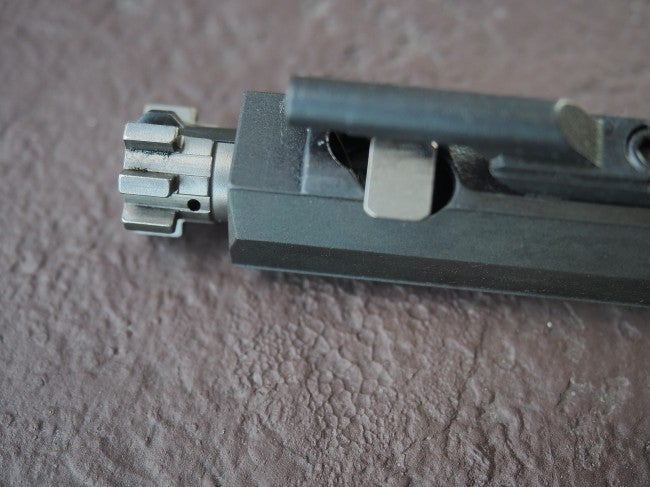

AB Arms uses a manufacturing process different than other makers of BCG’s and bolts. The company uses “Swiss” machinery, as they call it, to make their parts. The “Swiss” machinery uses a rotating method of cutting which AB Arms tells me is much more precise than the use of standard machinery used in most of the industry. This machinery is a good deal more expensive but turns out a much better product. Made to closer tolerances means less or no work performed on the parts after heat-treating.

The carrier itself is chrome lined with phosphate external coating. The cam pin and bolt are nickel boron coated. These two finishes make for a very smooth action as the bolt moves within the carrier. I’ve fired over 500 rounds without cleaning the rifle and still find the unit to work as smoothly as in the beginning. When I first installed it and racked the first round into it I noticed how smoothly it worked. My first thought was no way. I put my old carrier back in the rifle worked the action then put the AB unit back in the AR. I wasn’t wrong it was that much smoother. Honestly I had a hard time believing it having never experienced that much difference in carriers before.

After firing the 500 rounds I checked the BCG over for any signs of wear. There are none as the photos show. All of the other BCG’s I’ve used have shown wear on the parked finish.

I wanted to get more information on the process they use to make these units and why they chose the finishes they use. I gave them a call and talked with Jason one of the owners.

You’ll notice on the bolt it uses a phosphate finish on the extractor. The reason for that was they found the nickel boron finish to be to slick causing some slippage as the extractor grabbed the case. They went back to the phosphate coating for greater reliability during extraction. After experimenting with coatings they found the use of nickel boron on the bolt and cam pin working against the chrome lining made it very smooth in operation and increased the lifespan of the unit.

There is almost always some information companies can’t share and my next question was one he couldn’t give me specifics on at least not that I can share. I asked which companies they sold their BCG’s and bolts to. The best answer I can share with you is the ABM BCG/bolt is used in the majority of the very high end AR’s on the market. You would certainly recognize the names if I could share them. I honestly found nothing not to like about this product. It’s well worth checking into if you’re in the market for a BCG.

At a retail of $189.00 I would consider this a very fair price for the entire BCG and bolt. The full specs are listed below.

Statement from A*B Arms

“BoA*B Arms 5.56 Mil-Spec+ Bolt Assembly Nickel Boron Coated

Ready to drop into your bolt carrier group. These Bolts are specially made on high end Swiss machinery to have exacting tolerances and surface finish. A*B Arms is known by rifle manufacturers for manufacturing one of the finest quality bolts and extractors available. This has won us contracts with some of the highest quality AR manufacturers in the business. If you want to buy super high quality parts offered by the company that actually manufactures them, then you’ve come to the right place.”

Bolt

Carpenter 158 Steel

Heat treated per Mil-Spec Requirements

Shot Peened per Mil-Spec Requirements

MPI Tested Material

Nickel Boron Coated

Extractor

Aircraft Quality E4140 Steel

Heat treated per Mil-Spec Requirements

Shot Peened per Mil-Spec Requirements

Manganese Phosphate Coated per Mil-Spec Requirements

Bolt Assembly

Carpenter 158 Steel

Heat Treated

Shot Peened

MPI Tested Material

Nickel Boron Coated

Extractor

E4140 Steel

Shot Peened

Phosphate Coated

Bolt Carrier

8620 Steel

Phosphate Coated

Chrome lined bore

M-16 Style with more mass for better functioning in semi or full auto rifles

Gas Key

4130 Steel

Black Nitride

Gas Key Screws – 4140 Steel properly staked per Mil-Spec requirements

Cam Pin

4140 Steel

Nickel Boron Coated

Firing Pin

AISI 8740 Steel

Chrome Coated

Your Privacy Choices

Your Privacy Choices