The spring of a magazine is pretty much the hear and soul of the mag. It is what makes it work. Without it, it is just an empty box.

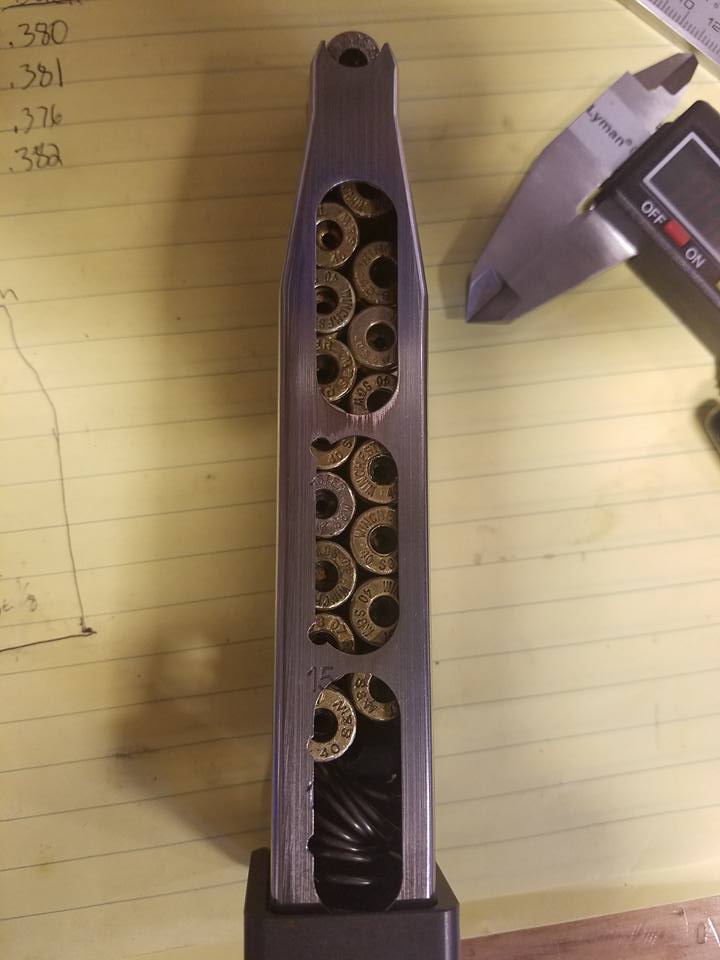

Atlas Gunworks showed a picture testing some .40s&w 2011 magazines. Just look at how twisted the mag spring is! To help show this issue, they cut windows into the 2011 magazine. That is not what I was expecting to see.

Your Privacy Choices

Your Privacy Choices