We introduced you to the concept of locking in a previous one of our 201-level posts on how firearms work, and today we’re going to talk about what has become the most common locking mechanism for rifles: Rotary locking. If to lock an action, you need to create an interference between the breechblock and the barrel, one of the most intuitive ways to do this is the same way a barrel bolt latch works.

You have likely seen one of these before. Its resemblance to your grandad’s hunting rifle is not a coincidence.

Like the latch, a rotary bolt rifle first has to move its breechblock – bolt – into position, then rotate it to cause the locking surfaces – called “lugs” – to line up with the locking surfaces attached to the barrel. These locking surfaces on the bolt and on the barrel or receiver interfere, preventing the action from opening before the bolt is unlocked during the cycle.

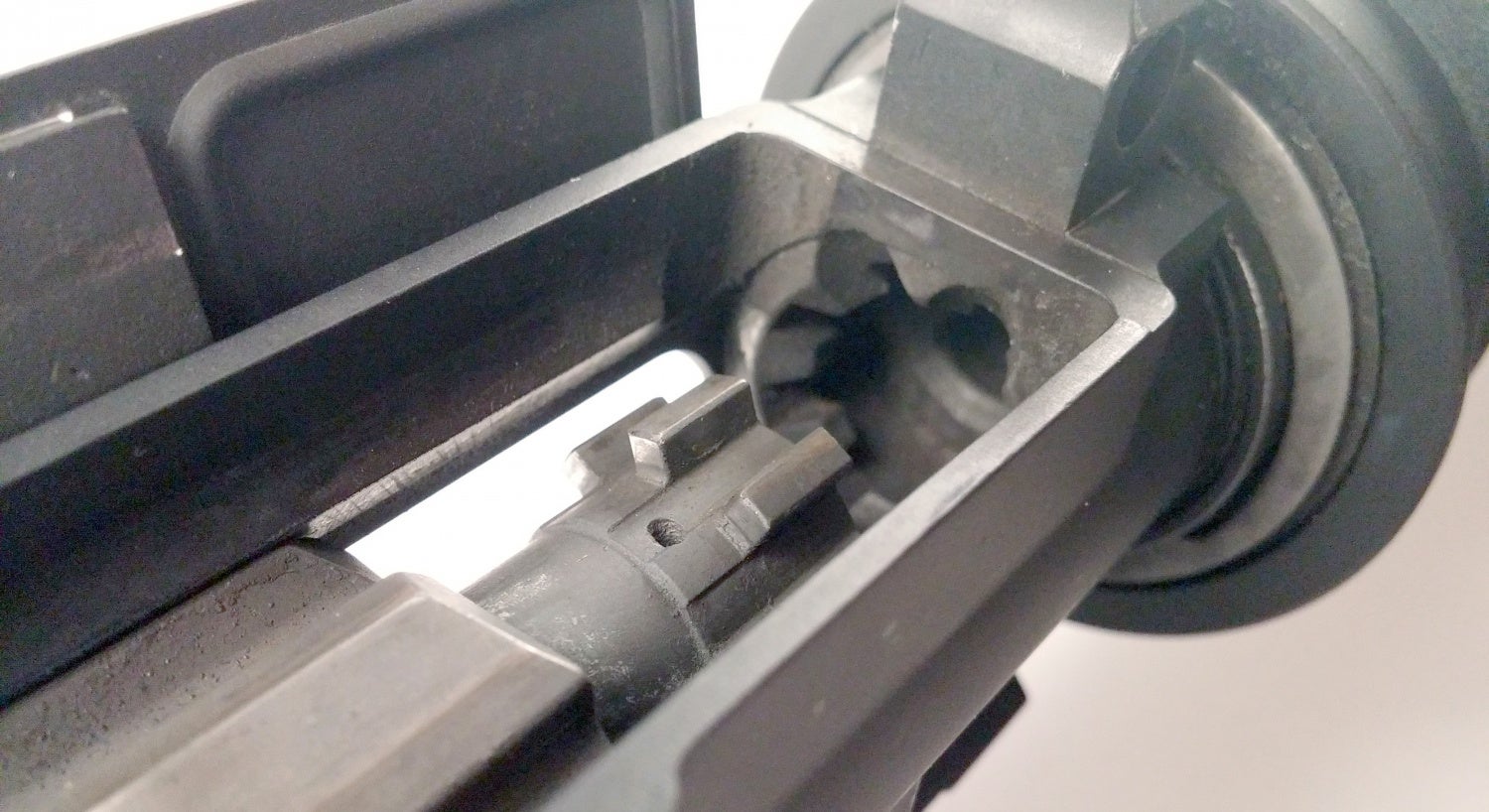

Many different kinds of rotary bolt configurations exist. The two most common, perhaps, are called “multi-lug” and “two-lug”, referring to how the lugs are arranged. An AR-15, for example, is a “multi-lug” firearm, using a set of seven evenly spaced lugs (in a pattern of eight, minus one where the extractor is located). You can see the “bank vault door” type locking of the seven-lug rotary AR-15 below; note how the bolt rotates until the lugs of the bolt rest against the lugs in the extension of the barrel:

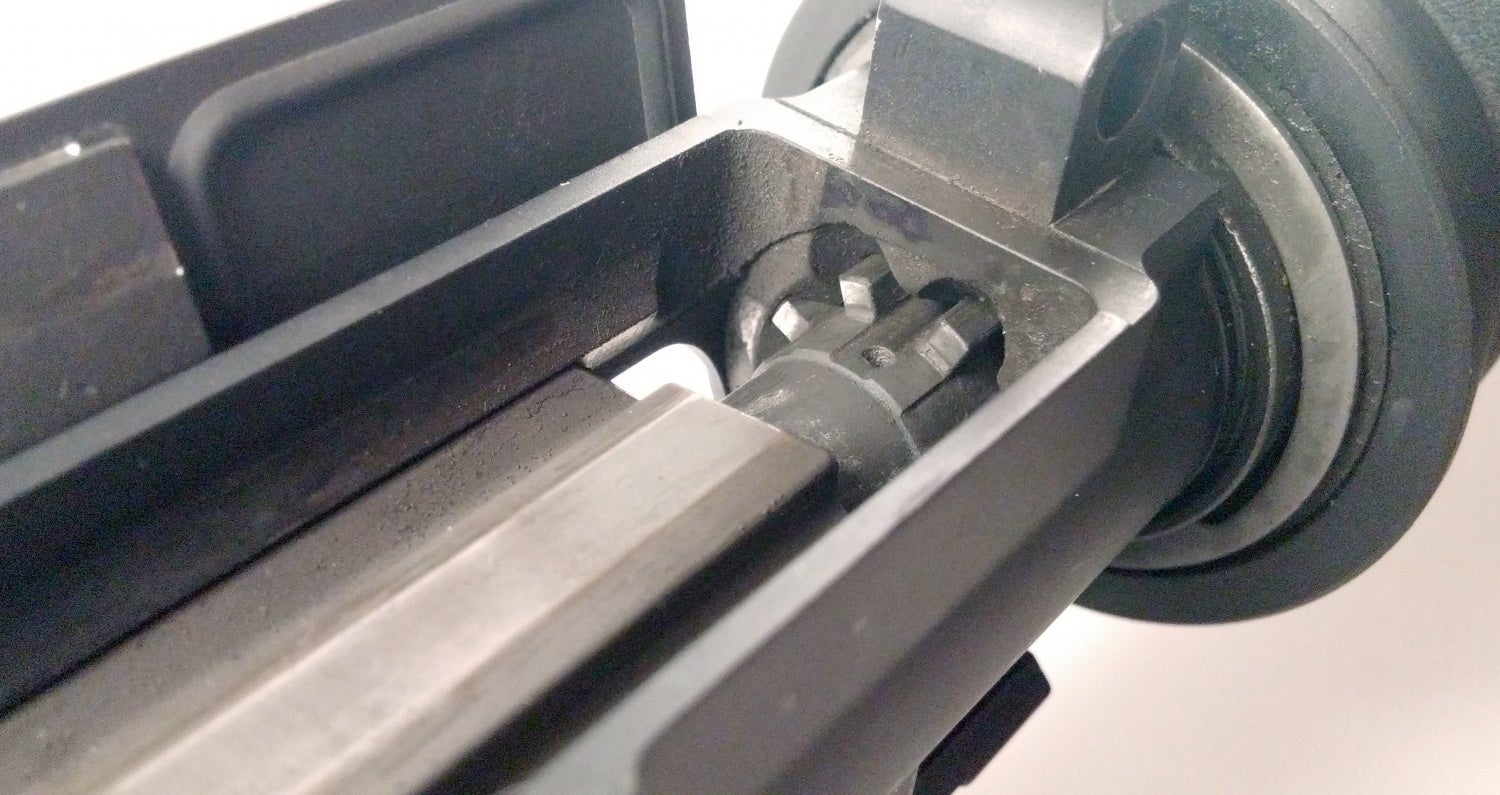

The M1 Garand also works via rotary locking, but it uses a different two-lug bolt profile, and instead of locking into a barrel extension, it locks into the receiver itself. You can see how that works below:

Rotary locking is valued for its strength, great accuracy potential, and simplicity. Because the lugs of a rotary locking firearm may oppose one another across the axis of the bore, the rotary locking system may provide a very even locking surface, helping to prevent warping and wear that could reduce accuracy or even cause an unsafe condition. The disadvantages of rotary locking include that it tends to not be very compact, and may be somewhat more complex to manufacture than other locking systems.

Your Privacy Choices

Your Privacy Choices