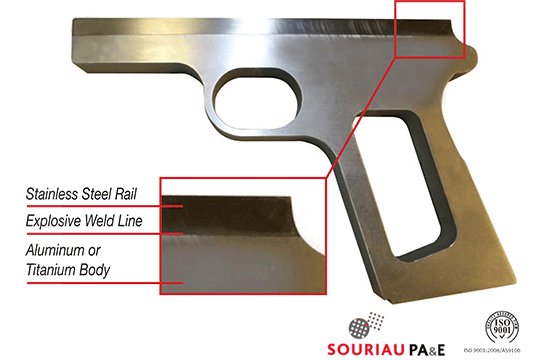

UA Arms makes a lightweight 1911-style pistol called IA 5.0. The gun uses a metal frame, which is made of aluminum or titanium combined with stainless steel. It is not an alloy, but the two metals are bonded together by a process called explosive welding. The result is a 1911 pistol with up to 50% lighter frame.

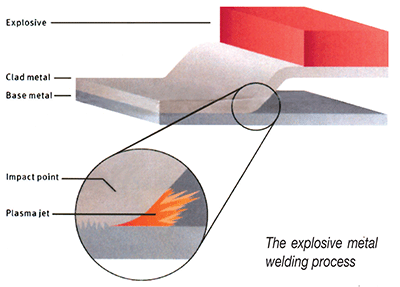

The explosive metal welding allows combining two different metals in a single piece. During explosive welding one of the metals is smashed into the another one driven by the force of exploding chemical compounds. So it welds the different metals at the molecular level and makes a clean and strong joint.

This method of manufacturing makes possible to use the benefits of different metals in the same part. In the case of the 1911 frame, this welding technique allows a stainless steel portion for the frame rails to ensure the durability, longevity and smooth operation of the moving parts. At the same time, the lower portion of the frame is made of either aluminum or titanium, which obviously makes the gun much lighter by replacing the heavier steel in the places, where you don’t really need steel. So the durability of the all steel gun is retained with the advantage of the lighter metals used. Well, at least it looks to be so in theory.

The explosive bonding process is used in space and naval applications, in the chemical industry and elsewhere. UA Arms claims that they are the first to use it in the firearms.

Although UA Arms uses this technology for 1911 frames, it is certainly applicable for other firearm uses too. I can think about a theoretical possibility to use this welding method instead of silver soldering, which is used in soldering double barrel shotgun barrels, vent ribs, iron sights etc. I am not sure if it can work there or does it superior to silver soldering in the mentioned applications. What do you think? Can this technology can be used in firearms industry? Let us know your thoughts in the comments.

Your Privacy Choices

Your Privacy Choices