That sharp, corkscrew section on the end of your barrel is called the ‘threads’. And it is completely ok to admit that is where your level of knowledge on barrel threading ends (until recently, I was right there with you). For those of us who run stock barrels and muzzle devices, you probably have never had the need to get into the weeds when it comes to thread specifications. But some mounting options remind us that not all barrel threads are created equal – a fact that is especially true when it comes sound suppressors.

Most gun/upper/barrel manufacturers should print their thread specifications either on the owners manual or on the product page of their website. And some muzzle devices actually have the thread infomation stamped or engraved directly on the mount itself. But what if you have an older rifle or an imported pistol where you are forced to do a bit of research before buying a new piston or mount?

While your best bet is to take your gun to a qualified gunsmith, most of us like to a lot of the maintenance and customization ourselves. Luckily, there are some basic techniques you can use to find out more about your barrels threading without having to see a specialist.

Standard vs Metric:

- Most US made components are threaded to US/English/Standard specifications. These threads are measured in Threads Per Inch (TPI).

- Most foreign components are threaded to Metric specifications. These threads are measured in pitch, which is the distance between adjacent threads.

Both types of threads can also come in either left or right handed twist, but in the barrel-world, Metric specs are more likely to be a different “handedness”.

From the Screw Thread Wikipedia page:

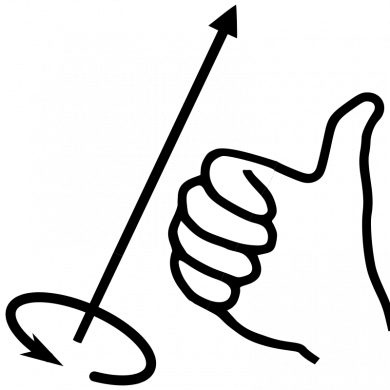

The helix of a thread can twist in two possible directions, which is known as handedness. Most threads are oriented so that the threaded item, when seen from a point of view on the axis through the center of the helix, moves away from the viewer when it is turned in a clockwise direction, and moves towards the viewer when it is turned counterclockwise. This is known as a right-handed (RH) thread, because it follows the right hand grip rule. Threads oriented in the opposite direction are known as left-handed (LH).

By common convention, right-handedness is the default handedness for screw threads. Therefore, most threaded parts and fasteners have right-handed threads.

Rotating rockets are cool!

Some shooters prefer mounts that come in left-handed threading. The theory is that with the rotation of the bullet in the same direction of the threads, the mount might have a tendency to “walk” or loosen.

Here is basic diagram of thread attributes:

Credit: http://specbolt.com/technical.html

Here are two examples of common barrel threads:

US/Standard/English

1/2″x28

1/2″ – Outside Diameter

28 = Threads per inch

Credit: https://www.boltdepot.com

Metric

M13.5×1 RH

13.5mm – Outside Diameter

1 – Thread Pitch

RH – Right Handed Twist

Credit: https://www.boltdepot.com

Silencer Shop has a good write-up on certain firearms and their thread patterns here: http://blog.silencershop.com/common-barrel-thread-reference/

I’ve summarized the basics:

.22 LR

- Standard 1/2×28

9mm

- Standard 1/2×28

- Standard 1/2×36 – Some 9mm carbines

- M13.5×1 LH – H&K, Sig Sauer

.40 S&W

- Standard: 9/16×24

- M14.5×1 LH – H&K, Sig Sauer

.45

- Standard: .578×28

- M16x1 LH – H&K USP Tactical uses the

- M16x1 RH – H&K Mark 23 (Socom)

5.56mm (.223)

- Standard: 1/2×28

- M13x1 LH – Steyr Aug

- M15x1- H&K

- 9/16×24 – Ruger Mini

7.62mm (.308)/.338LM

- Standard: 5/8×24

- M18x1 – Sako TRG

- M18x1.5 – Accuracy International

- M14x1LH – Some AK47 patterned rifles.

- 3/4×24 – Desert Tactical Arms

Why all the different sizes for different calibers? Because the differences in bore diameter will change the amount of leftover barrel material (sometimes referred to as ‘meat’) for threading. Smaller bores can have smaller threads.

There are also several YouTube videos on barrel threads. Here’s a couple to review:

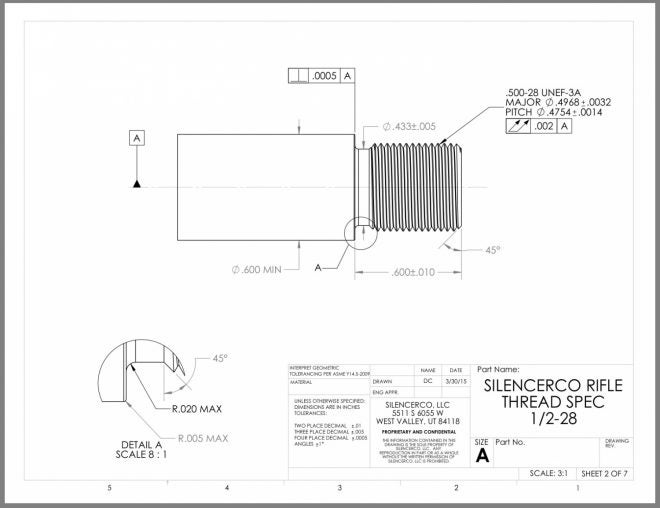

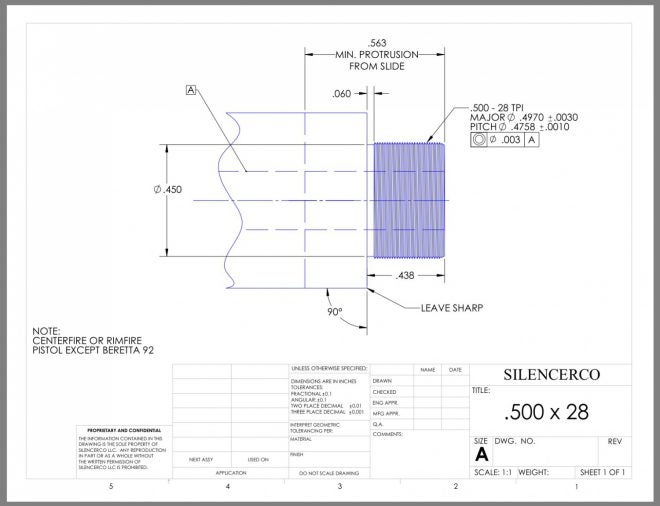

And just to complicate everything a little bit more, some suppressor manufacturers call for their own subset of barrel threading specifications. They should provide schematics that a machinist can use to cut a barrel correctly. As an example, SilencerCo has two different thread patterns for 1/2×28 – one for rimfire silencers and one for centerfire rifle silencers. Their rimfire suppressors use an o-ring engagement surface that needs a special cut to take full advantage of the mount.

Also, another important distinction: 1/2″x28 rimfire threading should be cut to a total length of 0.4″ whereas 1/2″x28 centerfire should be cut to a total length if 0.6″ – a fact that is missed by some barrel manufacturers and machinists. This can cause some suppressors to index/seat on the blast baffle rather than the barrel shoulder.

Final thoughts: just because your barrel is threaded, doesn’t meant that it is ready to spin on a silencer. Some barrels, the AK variants for instance, are notorious for being out of spec. While this is usually ok for a flash hider or muzzle brake, using inadequate threading with a sound suppressor is asking for trouble.

Barrel Threading Basics – And that’s The More You Know

Your Privacy Choices

Your Privacy Choices