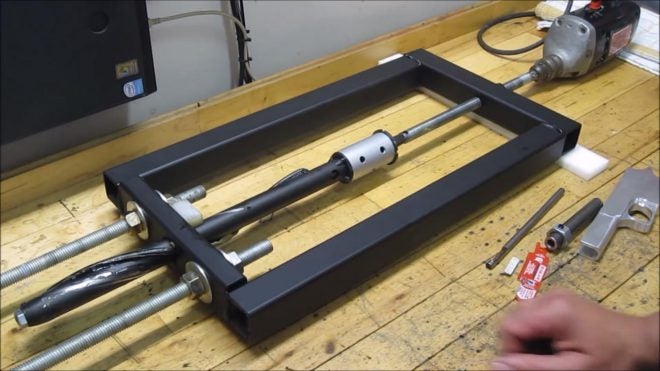

Last August I posted an article about Clinton Westwood’s DIY barrel rifling tool. Well he has updated it and motorized it. He used an old bicycle for parts and re-purposed it to drive the rifling tool. It acts as a differential. One side has the barrel twist rate while the other has the screw drive driven by the power drill.

Clinton is building a .380 semi auto pistol.

Your Privacy Choices

Your Privacy Choices