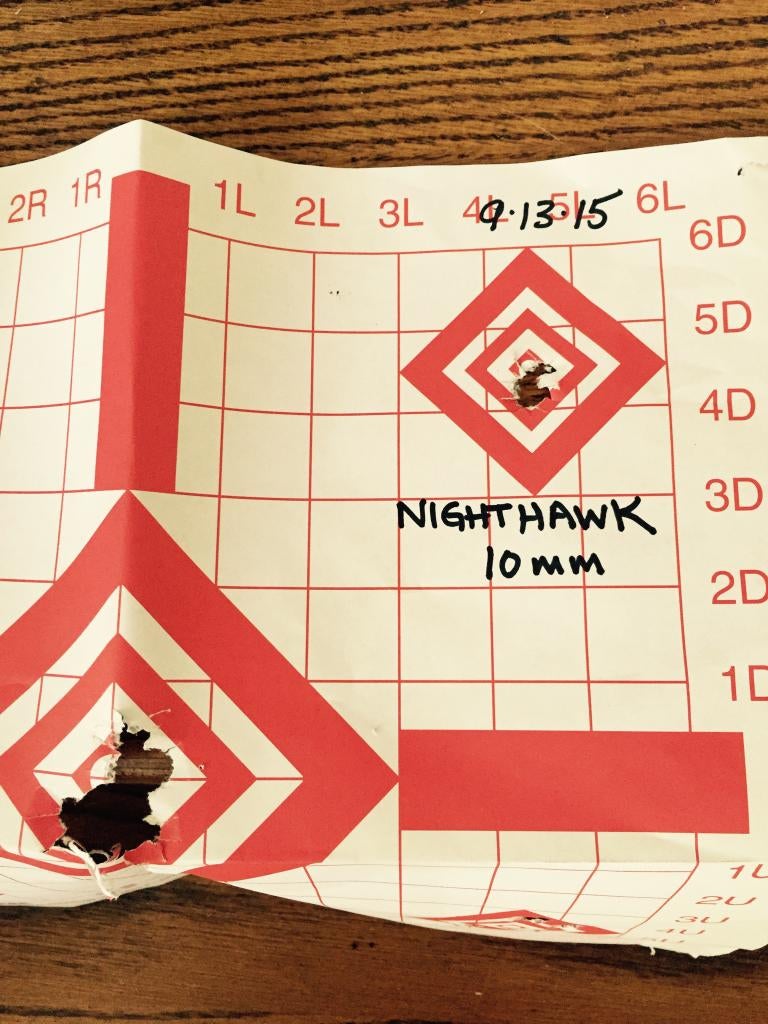

My friend Greg sent this to me. His friend had a Nighthawk 1911 chambered in 10mm. He said it was the most accurate handgun he has ever shot. Until it exploded.

From what my friend Greg was told, his friend was using off the shelf Armscor 10mm ammo.

1911s don’t explode as easily as polymer framed pistols. However this one was spectacular.

If you look at the picture at the top, you can see the chamber is split. I am not sure how that caused the slide to split down the middle, top and bottom. Then look at the damage to the dust cover of the frame.

When I saw these pictures the first thought in my mind was “Is the shooter ok?”. Greg assuaged my concerns and told me his friend received no harm from this accident. I think that is something remarkable about this Nighthawk 1911. It received this much damage from the 10mm round but the shooter was ok. Not sure if it was luck or due to the high quality that Nighthawk is known for. Unfortunately the shooter was unable to find any remnants of the round that detonated.

Nighthawk has never seen anything like this before and are building the owner a new gun as I post this.

Your Privacy Choices

Your Privacy Choices