Starting where I left off on part one of the Ilion, Ny Remington plant tour let’s move on shotguns and a short tour of the rifle area and what goes into parts making and assembly of these guns.

One assembly line I saw was very welcome sight and that was the V3 shotgun. The V3 is the newest shotgun Remington has released. V3 Post

It never ceases to amaze me how quickly an experienced team on the line can put a gun together and test it. Assembly and function test takes right at five minutes tops. The assembly starts with the barrel, sight installation, magazine tube attached to the barrel. This is then mated with the receiver after the second worker attaches the buttstock to the receiver. The magazine tube spring is installed along with the standard parts used in feeding and ejecting rounds such as the trigger group. Finally the action of the semi auto is checked after the shotgun is lubed. A ticket is filled out with the serial number, date and who signed off on it. The shotgun is then placed in a rolling rack. When the rack is full it’s moved to another area where it’s inspected again and then boxed for shipping.

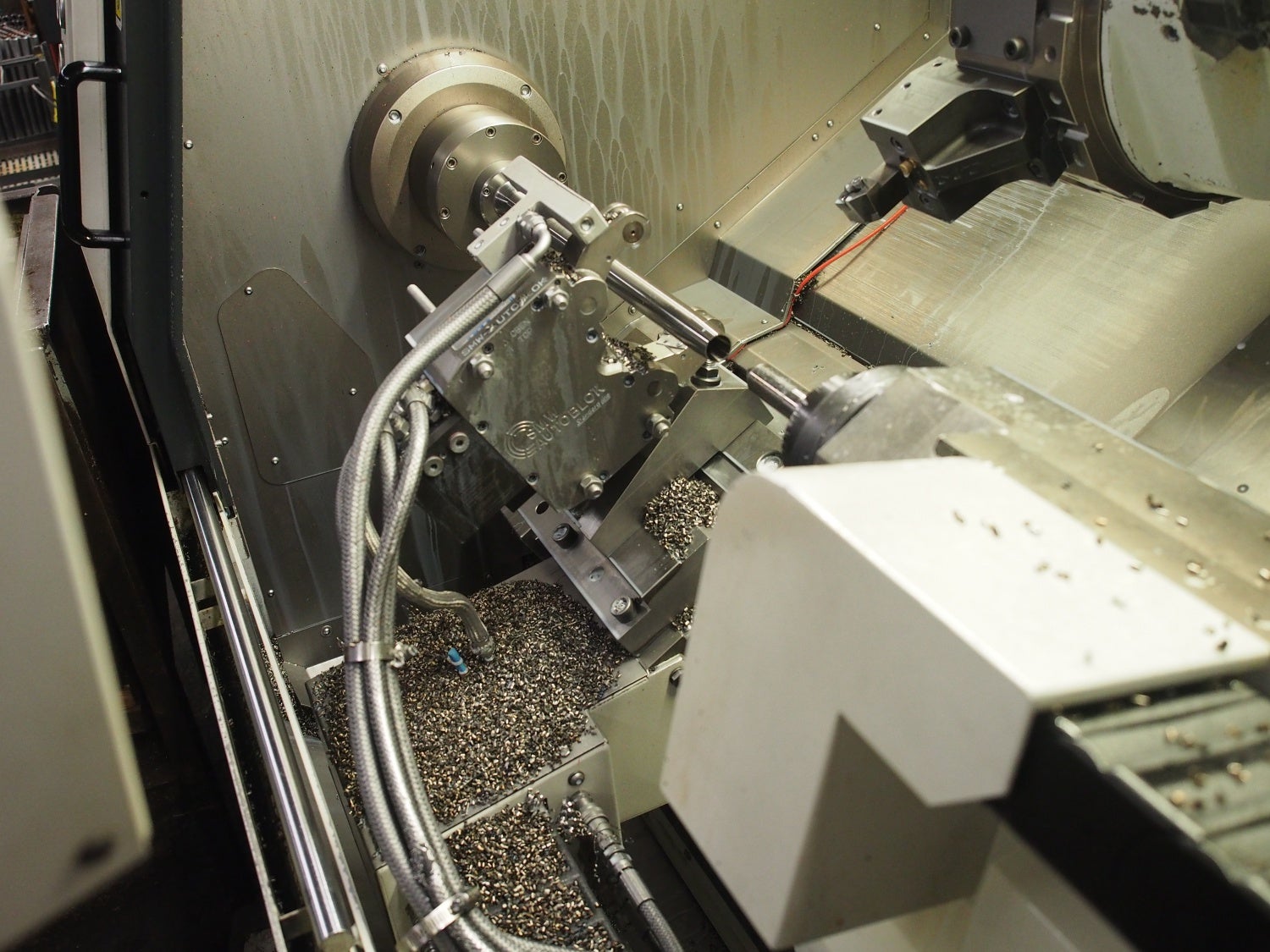

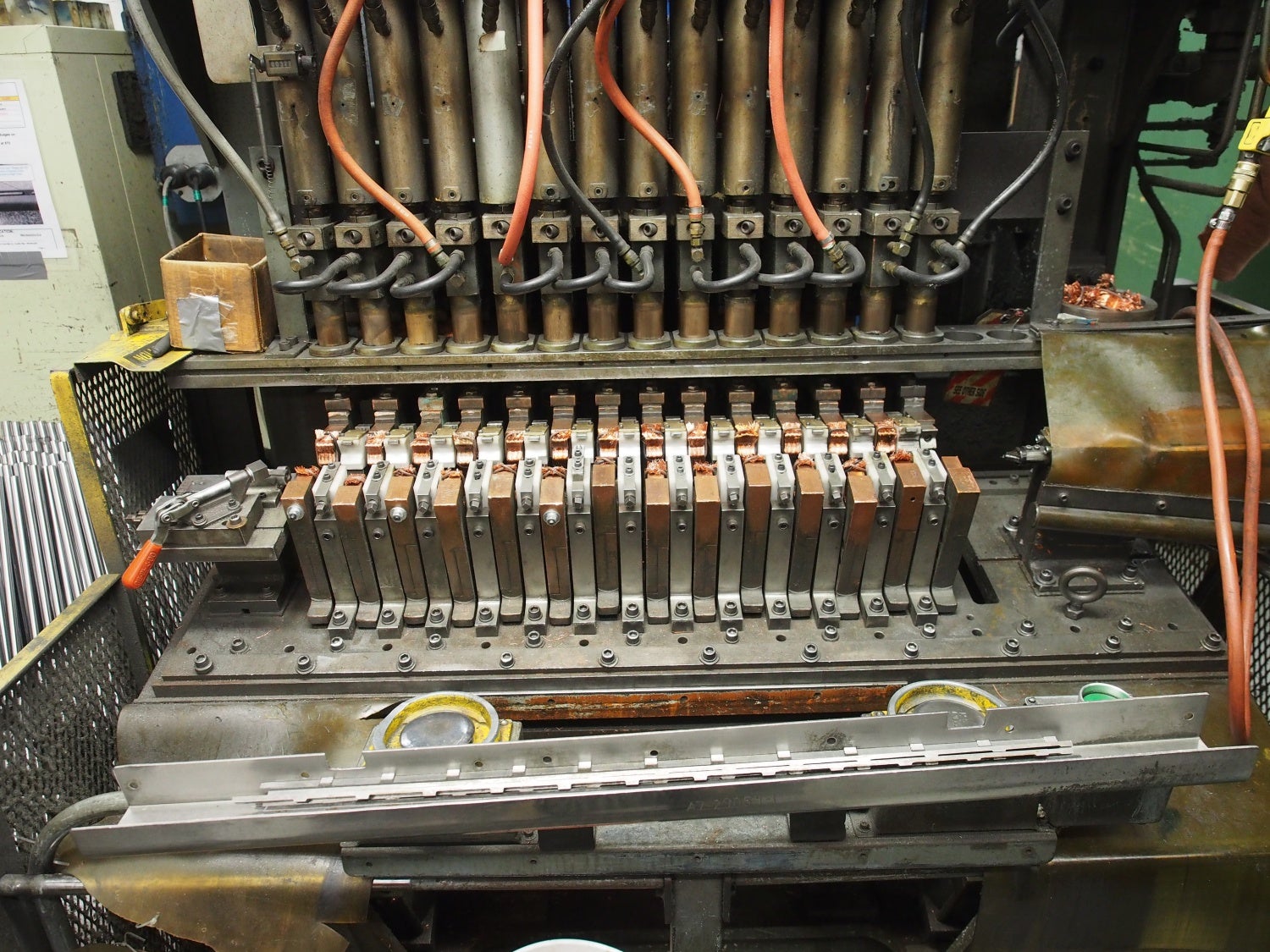

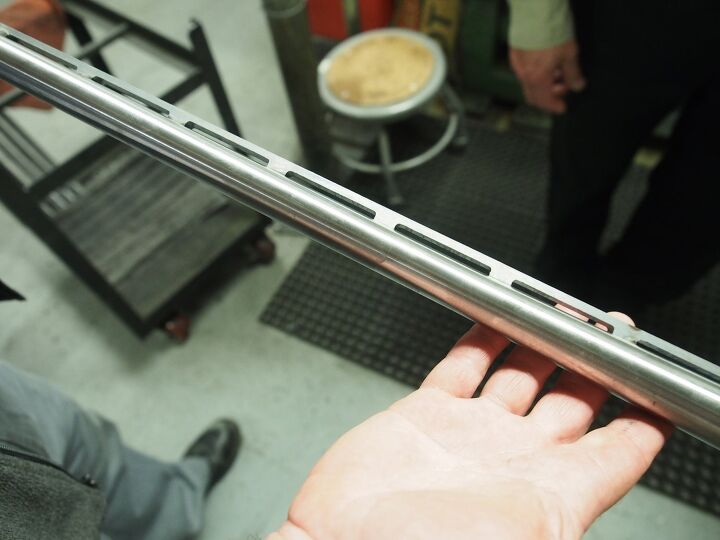

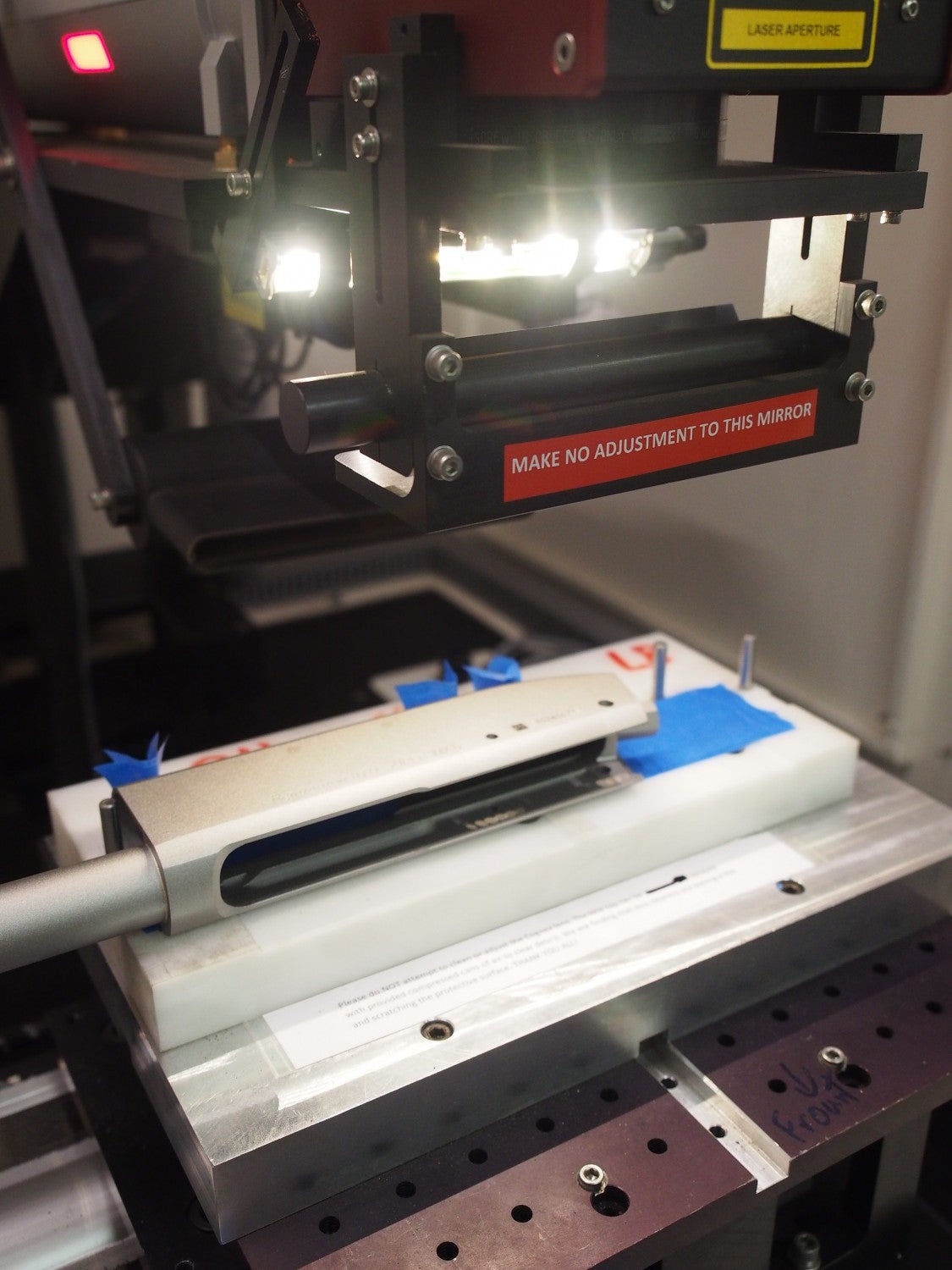

Let’s talk barrels and show the process of creating and finishing them. The photo caption tells the story.Before we get into barrels let’s look at the raw material for an 870 receiver.

Blocks of raw material for shotgun receivers. One raw block shown next to a partially completed receiver. Each raw block weighs over 20 pounds.

After touring the shotgun and Marlin area we moved up one floor to the rifle manufacturing and assembly area.We were running out of time so we couldn’t cover as much of this area.

Various Remington 700 Models. These special orders are complete and ready for inspection, packaging and shipping to the customer or police departments.

As I mentioned earlier we only had one day to cover the entire 1,000,000 square feet as well as the museum. That said we were unable to do as much coverage of the rifle area as we would have liked. Also at the time we were there the DOD area was off limits. They were doing some long range firing underground in the old Erie canal range. Of course anytime you deal with a DOD area you have to follow the government rules which are always more strict than the company rules.

I would like to thank all of the special people we met who create these Remington shotguns and rifles and have devoted their lives to making a quality product. These workers and supervisors really do bleed green and are the heart and soul of the company. Everyone we met was very accommodating and helpful in answering our questions and showing us the areas they work in. I would also like to thank all of the management team and J. Kallum who set this tour up and took care of us in seeing things we were interested in as well as briefing us on the company structure as well as future plans for Ilion. It really was a fascinating place to see with the old mixed in with the new. You can just feel the history as you walk through the plant.

I hope all of our readers have enjoyed the articles on the museum, the company history and the Ilion facility as a whole. I’ll conclude the articles with the next part of the tour when we arrive in Huntsville, Al. I hope you enjoy it as well.

Your Privacy Choices

Your Privacy Choices