Aim Surplus (AIM) is a popular online retailer of gun accessories, firearms, and military & police surplus. What many may not know is that AIM is a huge seller of bolt carrier group (BCG) for AR style rifles. AIM’s customers had purchased over 50,000 of the AIM basic AR-15 BCG so far. The popularity is partly because of AIM BCG models are usually priced anywhere from 30-50% cheaper than what most AR-15 manufacturers are selling theirs.

AIM is now offering a number of higher-end BCGs in addition to their basic model. Just released is the new AIM Lightweight BCG for AR-15. It comes in the Nickel Boron finish for $119.95 or in black Nitride for $109.95 with free shipping for both. The total weight is just 8.5 ounces or 28% lighter than the standard BCG.

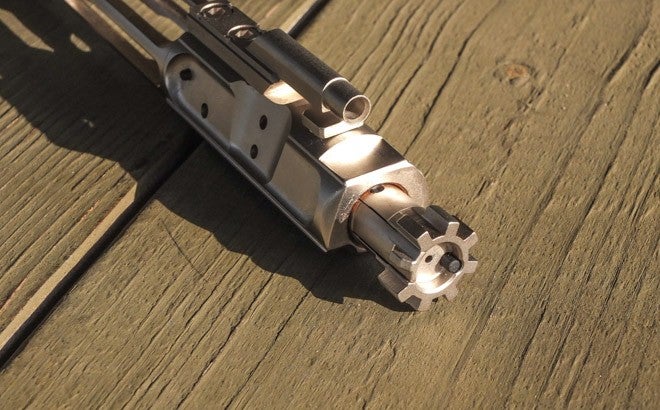

On my nickel boron sample, just about everything are nickel boron coated with the exception of the ejector, the firing pin and the firing pin retaining pin. There are many advantages of the nickel boron coating over the traditional phosphate finish for BCG, those including low fiction, self-lubricating, and more resistant to wear.

I tested my AIM Nickel Boron Lightweight BCG sample in my 14.5-inch lightweight carbine during the recent Big 3 Media Event. Due to the reduction of the weight, AIM is recommending use their lightweight BCG in conjunction with an adjustable gas block. Of course, I didn’t do that. All I did was replaced the original BCG from the BCM upper with the AIM BCG. My AR-15 ran with it without any issue.

The image was taken after over 250-rounds of WPA (brass and steel cases), ZO1, HPR, and Fiocchi ammo were fired during the Big 3 Media Event and the destruction of the BMW car at the end. There’s hardly any carbon build-up on the AIM lightweight BCG as seen in the image. Also for the testing purpose, I didn’t put any lube on it. There were no stoppage of any kind even running it dry.

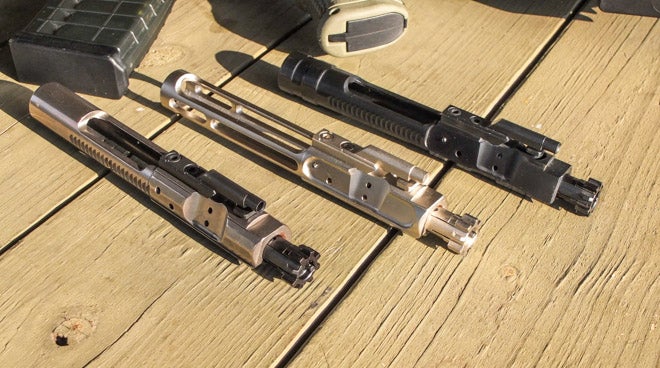

Beside of the new lightweight BCG, AIM Surplus also offer the full size BCG-X model ($109.95) on the left with a mix of nickel boron and black nitride components. To the right of the AIM lightweight BCG is the AIM Evolution 3.0 reduce-fiction nitride BCG ($99.95). I will cover both of those AIM BCGs in another review.

My testing AR-15 carbine leaning against the burned out BMW the day after on the Big 3 Media rifle range.

A short clip of me doing more testing after the Big 3 Media Event. From that, I would say AIM is right about suggesting using their lightweight BCG with an adjustable gas block, which would help reduce the recoil and making it a smoother shooting gun.

Your Privacy Choices

Your Privacy Choices