As part of the Big 3 East Media event, we got invited to tour the SCCY factory. For those of you who are not familiar with SCCY, they make the CPX-1 and CPX-2 pistols.

SCCY was originally called SKYY. But the vodka people had issues with that. So they changed it to SCCY and it is pronounced “SKY”. Joe Roebuck, CEO and founder, is an aviation aficionado and it is apparent in the office and the inspiration for the name of the company.

Joe Roebuck gave the tour himself with my group. Joe is a tool and die man by trade. He worked in the medical industry for some time. A California company contracted some firearm tooling and left him hanging. So to “make lemonade out of lemons” Joe decided to try and make firearms himself.

Below is an original slide that he made that was MIM (Metal Injection Moulding). He abandoned this process and started from scratch. He went with full CNC of all the metal parts. Other than the springs and polymer, everything else is made in house. They are already looking to expand their 21,000 sq ft facility to a 50,000 sq ft facility and bring the polymer injection molding in house as well as ramp up for their future product line expansion.

The factory was remarkably pristine. A common comment was that it was like a clean room.

Those long gray colored machines are a giant hopper for bar stock to feed the machine that makes the firing pins.

An employee inspecting some parts.

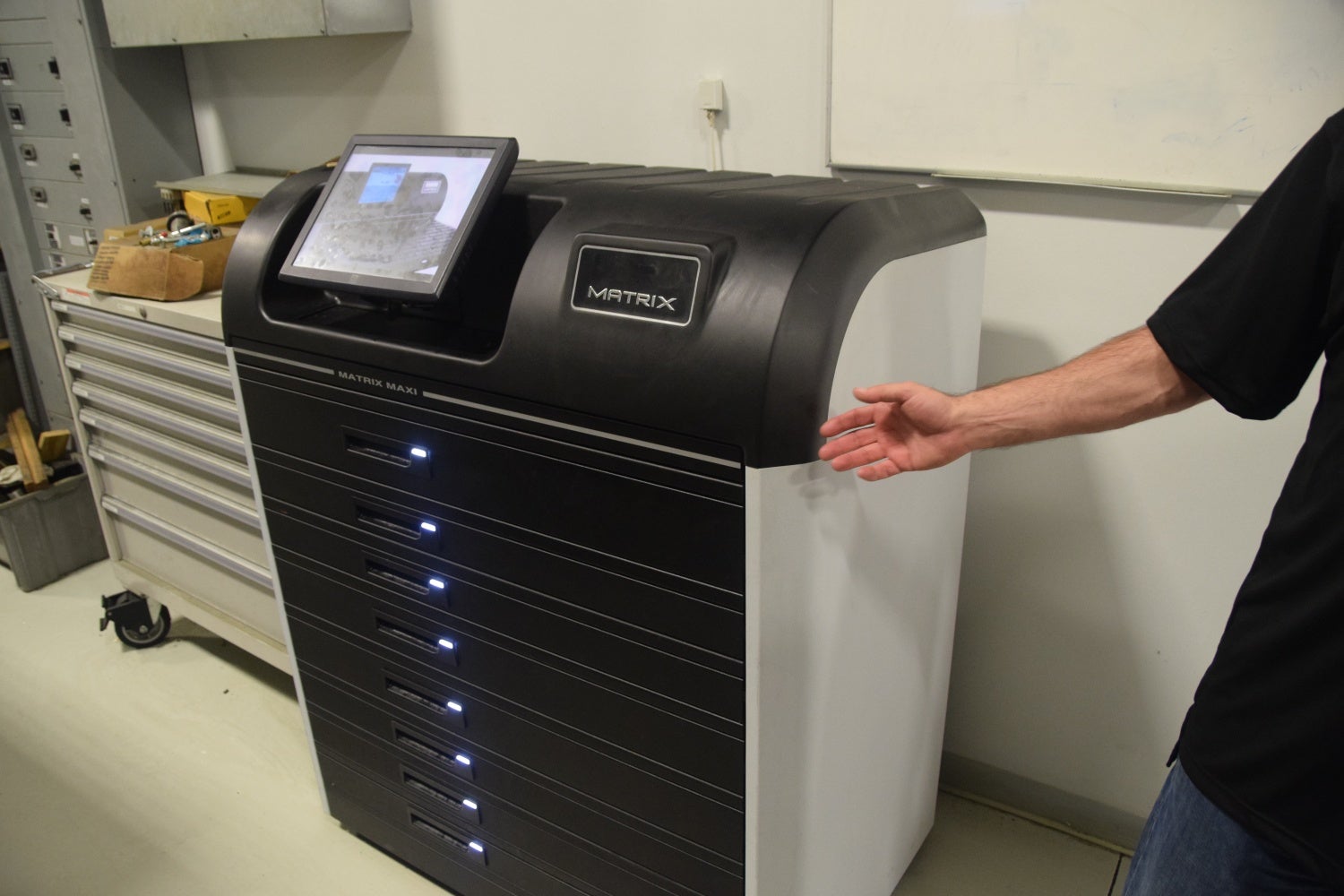

Here is their tool inventory system. When a machinist needs to replace a tool for the CNC, They log into this machine, place the old tool in the tray and grab a new one, The Matrix maintains this inventory and will update their computers so they know when to order more when needed.

One of the primary ways Joe keeps costs down is to design and make is own tooling. He has a room dedicated just for this purpose. He uses a wire EDM for a lot of his tool making.

This is the only manual machine he has.

Here is a tray that an employee will load with barrels and a robotic arm will take each barrel and load it into the CNC.

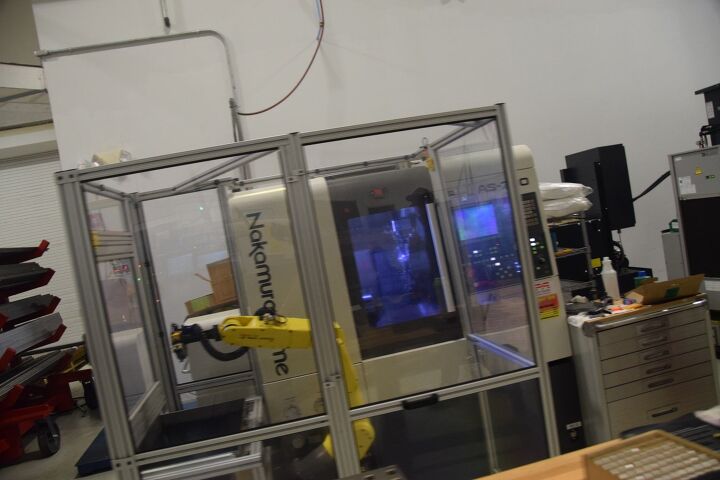

Here is the machine that loads the barrels to machine the chamber and feed ramp.

Before and after the machine above does its work.

Here are some raw slides.

The process to machine their slide is only a 2 stage process. They take this hex shaped bar and machine it twice and out comes a slide.

An impressive 50% of each part is tested against the specs.

Polymer frames ready for assembly

Assembled guns ready for shipping.

A sneak peak at a new color offering, white.

It was incredibly intriguing to have Joe Roebuck give the tour himself. You can get him talking at length about the nuances of design for his tooling and the methods of manufacturing just those components. He is a fascinating person and loves what he does.

Your Privacy Choices

Your Privacy Choices