Assuming their data is spot-on, Elzetta flashlights has called out the bear in the industry, Surefire. Sure, its a convenient marketing ploy, but if the data holds true, its an interesting analysis of an industry-standard specification that many consumers may not be familiar with.

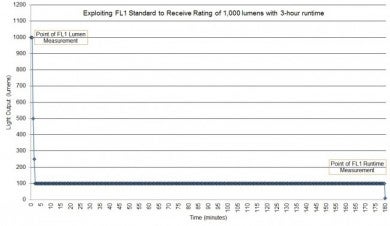

in a recent blog post , Elzetta goes into detail behind the ANSI FL1 ratings and how they can be manipulated. The standard measures output at 30 seconds after activation only, allowing manufacturers to “game” their ratings by lowering output after measurement to prolong battery life.

An example of extreme gaming of the FL1 standard not typical to any light, but possible.

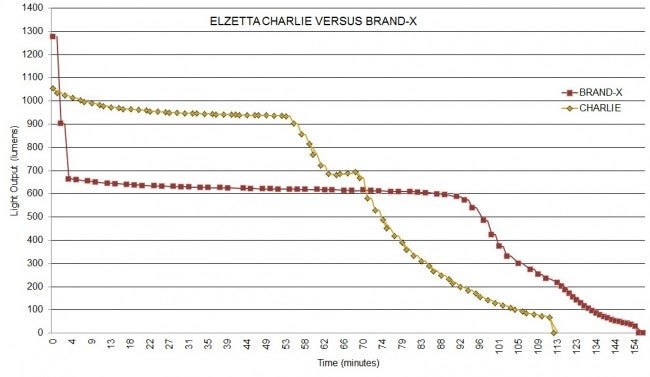

In a not-so-subtle jab at Surefire’s new P3X Fury compact flashlight, Elzetta breaks down how a (very similar) light gets is stellar ratings far and above most competition. In short, they allege that the light games the FL1 rating and can only output peak lumens for a very short duration. They even go so far as to allege that the (very similar) design could be a “safety concern” due to how the light overdraws the batteries.

How a light can game the specification. The gold line is Elzetta’s offering. The red line is the (very similar) light to the P3X

My experience shows this is common across multiple industries. In my “day job,” my primary competitor fully stretches various specifications to their marketing advantage, leaving customers with high expectations and disappointing results. While it does make room for my products in the market, I fight those misconceptions daily. In my opinion, gaming specs hurts any industry where it is easily pulled off.

I, for one, wish the FL1 spec was re-written to account for output over time.

As always, if it sounds too good to be true, it probably is.

Your Privacy Choices

Your Privacy Choices