Now, before you roll your eyes at yet another 1911 manufacturer, I encourage you to hold the skepticism for just a moment. I’ll admit, when I arranged the factory visit I was interested, but not expecting anything out-of-this-world. By the time I left, I may have taken a real interest in 1911s.

I was hooked-up with Schroeder Bauman (SB) (note, not Schroder & Bauman), through my local range. When I visited to set up my membership for the year, Mike the General Manager was raving about the three new 1911’s that he just got in. He offered to let me handle them (why would I refuse any new gun?) and I was generally ambivalent. The SB full-size model felt good, but it was a 1911. Interestingly, it had finger-groves machined into the frame. My impression was a resounding “meh.”

(Author’s note: I do not consider myself a “1911 guy.” I like them, appreciate them, shot them many times, but I prefer other styles of handguns.)

What did pique my interest was that Mike mentioned SB was based out of Fort Wayne, Indiana. I found they were a scant ten minutes from my home. Mike linked me up with Jay Morley, SB’s President. After a short call we set up a time for me to stop by, poke around, and take a few photographs.

Schroeder Bauman is located in a nondescript manufacturing park in an otherwise outwardly boring area of the city. Ashley, complete in safety glasses and gloves, met me at the door and escorted me back to the assembly room. There, Jay was personally assembling a Officer’s model. Even with the door shut, there was a dull roar of CNC and other machines working in the background.

Jay Morley, the President of Schroeder Bauman right at home behind an assembly table. Jay is much happier running a machine than a company.

After pleasantries and a cup of coffee, we started delving into the history of Schroeder Bauman. Started by Jay, Ashley (who I found out was his daughter) and a third faithful employee, SB was originally going to be retirement “fun.” Jay is the former owner of SWS Trimac, an “electron beam & laser welding, metal fusion, and machining solutions” company originally started by his father. Long story short, if there is a material out there, Jay and SWS tried to fuse, weld, or work with it. Jay has parts on almost all of the US fighter planes and a few even in space.

Still, he’s humble, always deferring to the contribution of his staff and partners. In fact, Schroeder Bauman is named after two of the principal machinists who worked on the prototypes.

I then made the mistake of asking, ” What separates Schroeder Bauman from all the other 1911 companies out there?” Jay winced a moment, but I could see a passion frothing to come forth. It did.

SB’s custom-built one-off 22 Short Gatling (hand-cranked semi-auto). Beautiful polished brass. SB custom made magazines to feed it.

“John Browning used the best materials available at the time,” stated Jay, “1050 carbon steel was strong, but brittle. We have come a long way since then.” . With his background in materials sciences, he explained the material choices he made. Of interest to myself was when he started to explain how some metal pieces can fuse together, in a process called cold-welding. In short, two highly polished and pure pieces of metal, when pressed together, will exchange electrons and form a single piece of material.

To counter this, SB fuses ceramic material into the rails on both the frame and slide. Not just a simple coat, the ceramic material interacts and stabilizes the steel rails, increasing lubricity, toughness, and yield strength.

Jay redirected me to a picture of what seemed to be a pale bronze 1911. “It’s one of two we made that can run completely dry.” They infused the metal through a new welding method to have previously unheard of lubricity. “We ran 500 rounds through it of the dirtiest, crappiest, Wolf we could find with no issues.” I believed him, but challenged him to put it on video with TFB’s staff.**

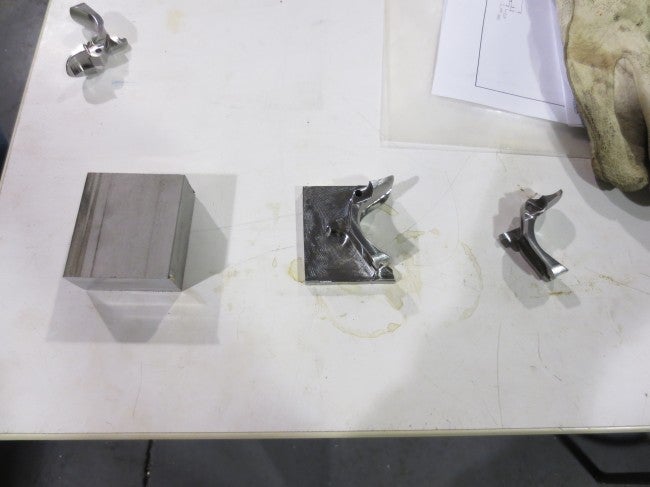

Everything on the SB 1911’s except the barrel (they use Storm Lake), springs, and trigger are all made in-house starting from solid billet. There are no forged parts in their pistols. They hold their tolerances and quality standards high. For example, the only pistol available for me to test was rejected from shipment because the front strap etching was just out of spec. Having handled the demo gun and a production-approved model, I could not tell a difference.

All of the major components are machined in-shop. Pictured above are frames in various stages of machining.

“Don’t buy a that guns that have to be shot in, or that you have to select and test certain ammo,” opined Jay. SB’s guns are all designed and tested to work all the time with any ammunition. A Virginia SWAT team tested SB’s guns versus a few competitors and SB’s came away the clear winner. (Note, SB did not share which SWAT team did the testing).

This level of fanatical quality does not come without expense. The American Defender (full-size model) ranges from $2,000 to over $2,500. The officer sized Liberty ranges from $1,300 to $1,779, depending on the options. Pistols ship with Chip McCormick magazines. Compared to other high-end 1911s, these are a bargain.

Distributed through AGSArmament, SB pistols are available for FFL’s country-wide. Be warned, demand for the pistols is high and you may have wait for one to come in or search hard for the model you want.

SB is doing complete custom orders including but not limited to serrations, front strap profile, custom engraving, etc. Contact them directly through their website for custom build or use their online tool to get a general idea of the look and feel.

I am fortunate that SB is loaning a firearm for a full work-up and review. Serial number 13-0013 has seen “over 6,000 rounds” prior to my review. SB claims that there have been no spring or component changes in the pistol. Stay tuned for the full work-up and to see if Schroeder Bauman lives up to my positive first impression.

- Frames ready for more machining.

Update: Fixed a few grammatical errors (thanks to our eagle-eyed readers!) and changed some minor wording.

**Correction: SB contacted the author and pointed out an error. The run-dry firearm was not explosion welded. It used a different, “high-speed, low-drag” welding method.

Your Privacy Choices

Your Privacy Choices