Where I come from, people joke about watering flowerbeds with motor oil. Especially those parts where they’ve buried a machine gun. There are many semi rifles that people build from 80% kits and parts: AKs, CETMEs, Uzis and the “other one”. Not much selection of pistols. True pistols, not rifles bastardized down to be one.

I don’t have a problem with few existing pistols builds, but sourcing 49 individual parts is outside of the scope of my attention span, never mind fitting them together. A year ago I started to look for an ultimate SHTF pistol build. Something that has few parts and doesn’t freeze together in a trunk when I come visit uncle Vlad, up north. A year later I got something working.

Few people realize that some builds that take a page of write-up actually may span a year or more. Not 24/7 effort, but rather keeping them on the back burner while you try to figure out something like how the f did Germans crimped front receiver bushing on MG42. This true with many builds. Sometimes it’s hard to tell when you fertilized the new build, but I distinctly remember arguing with comrade Michael, last summer, on the simplest pistol in defense of Motherland. This is when I fell in love with Glock.

I appreciate simplicity. There is the beauty of symphony of parts that harmoniously come together for one, single purpose. None of that tacticool kakashki, with extra rails and extra screws. No rails! I can’t say that Glock design is perfect, like a fine middle game of chess where each move not only serves one purpose, but several goals at the same time, those goals interconnected many moves ahead. But Glocks work and they are very simple.

I don’t like polymers or aluminum because I can’t easily repair them. With steel, what angle grinder taketh, MIG welder giveth back. My original thoughts on building a pistol to use Glock parts was part polymer, part steel. And by “polymer” I don’t mean Nylon 6, mold injected, but more like bondo and some fiberglass cloth. Mold injection and 3d printing is soooo not SHTF.

One distinguishing feature of Glock is that frame doesn’t receive as much stress as pistols where its barrel is attached to its frame directly. This gives a perfect opportunity to slack off on the frame integrity and just weave it out of paperclips (next build idea?) I did experiment with a good number of molds and designs. One line of thinking was to make it like an investment casting, with cheap wax mold that could be used to make either epoxy based or aluminum (like in a lawn chair) cast. I struggled with was dimensional consistency and fragility of molds. The limited steel skeleton grew bigger, encompassing more tasks, and eventually became the top contender.

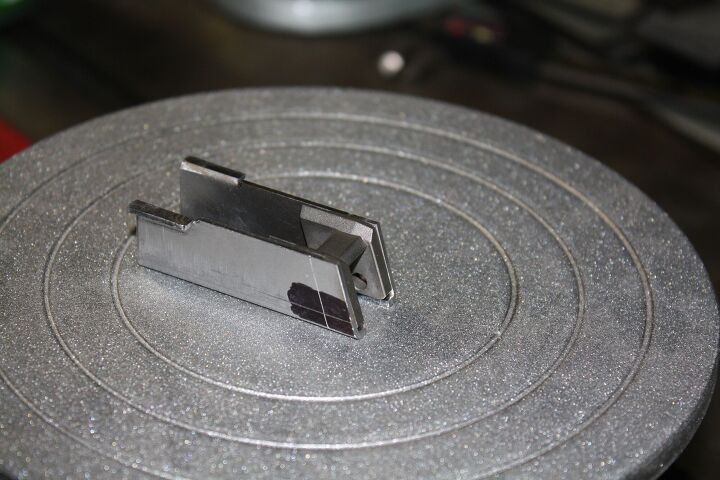

Current “Iron Glock” is actually 10-th major iteration of the 4-th model design. It’s predecessors were left in the scrap heap. Sheet metal stampings are frequently associated with cheap, fast production; however, when formed it creates uniformly thin, yet durable frame walls. Additional machining, forming and fitting can make stampings precise enough. This frame, although may not be perfectly suited as a factory production model is a great alternative for home built guns.

Combination of stamping and machining can give very good results. Here, position of the locking block must be perfectly flush with top rails, otherwise the timing of unlocking the barrel will be off.

It was written that Gaston fired his prototypes left-handed in case of gun blows up. If you’ve built a Glock, you’ll understand that he either did not design or understood it. The greatest knowledge comes when you screw up. It starts with frustration and throwing objects in immediate vicinity against the wall. Then comes liquid medication and a pensive period of self reflection. When you finally understand what went wrong, you commune with the designer and see the depth of wisdom that was put into every single little part

One interesting aspect of Glocks is the infamous angle and the grip that seems to shovel sand into some people’s privates. Although it was written that this angle was chosen as the most ergonomic to some Austrians, I think that the real reason is quite different. Magazine well angle is smaller than overall grip. My thoughts were to simply use that angle for a different feel, except that I could not. The grip must be close to the slide to avoid limpwristing and problematic cycling. That trigger mechanism housing with the ejector is just too bulky to hide anywhere else. There is no real solution here. If you want a different grip, that housing must be at least twice as short. That’s my opinion and I’m sticking with it.

I haven’t got around to dress the iron frame in anything other than quick solutions such as wrapping it in duct tape or unicorns. There is a potential to add molded grips, even to bond wood. In a 180 reversal I am coming back to plastic as the final solution. My guess is that airsoft manufacturers had to increase the size of their “replicas” to avoid the wrath of Gaston’s attorneys. This suits me just fine as the steel frame fits well inside the plastic that I was trying to replace to begin with.

….. and last but not least, the obligatory garden tool mutilation …..

Your Privacy Choices

Your Privacy Choices