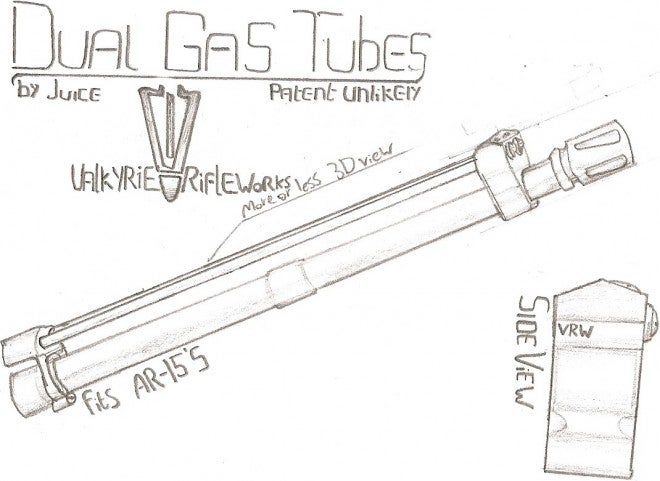

Joost, a reader of TFB, emailed us a sketch of an idea he had. He wrote …

The entire idea is basically deviding the pressure that goes trough a single gas-tube trough a dual-gas tube system, splitting the amount of gas 50/50 in the (low profile) gas block, and into the chamber.

The perk of this system is that the heat of the gas isn’t forced upon a singe gas-tube, and thus allowing for a faster fire rate for longer amounts of time.

Readers, how useful would such a system be? If fired continuously the gas tube of an M4 will heat up and eventually burst, as seen this torture test …

Your Privacy Choices

Your Privacy Choices