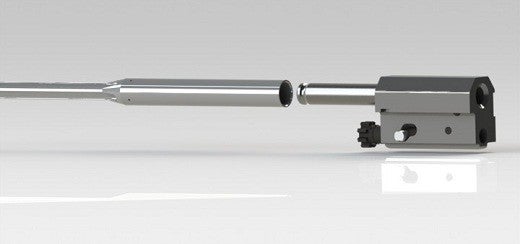

SARG XS2012 is a rifle that a TFB reader has been developing for the past couple of years. The first prototype is being put together right now, with its first live-firing in the not-to-distant future. It has a very clever gas system. The piston extends all the way to the rear of the bolt carrier, giving the gas a more space to expand and therefor decreasing the pressure on the bolt.

The term “delay” is simple in that the gas piston is affixed to the rear of the bolt carrier. The gas piston is about 6″ long, therefore in the actions full travel (around 4.8″) the piston is still inside of the gas tube preventing any excess gasses from bleeding into the chamber. The gas piston sits just slightly behind the loaded cartridge when the chamber is fully closed, theoretically eliminating barrel wobble and helping stabilize the barrel harmonics. And yes, it would be considered a long stoke gas system. It was designed to eliminate the accuracy problems abundant with long and short stroke piston systems, while keeping the Direct Impingement accuracy.

I am looking forward to seeing the first photos of this rifle.

Your Privacy Choices

Your Privacy Choices