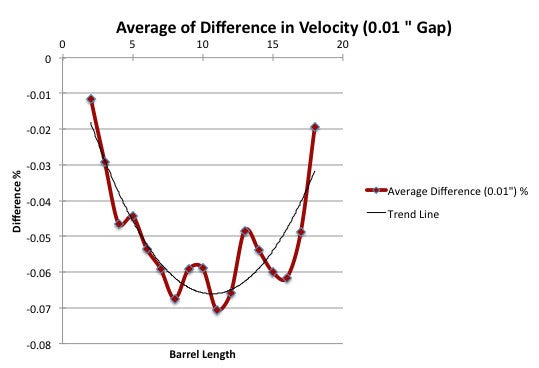

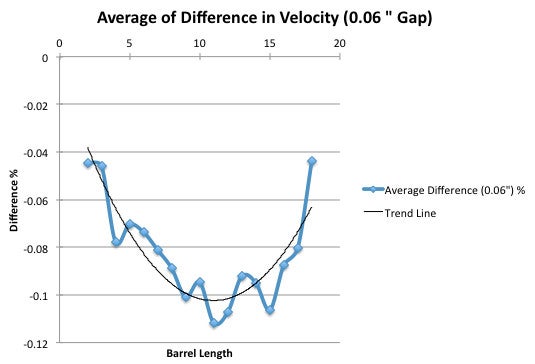

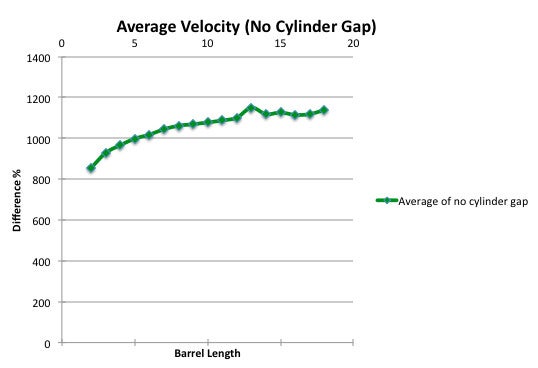

During the past few days I have been absorbing the data collected during the BBTI Project’s cylinder gap tests. I noticed a strange anomaly. For each of the cylinder gaps tested, as the barrel length increases so does effect on velocity increases (as compared to having no cylinder gap at all), up until a certain point, then the effect on velocity starts to decrease.

I would have expected that as the barrel length increases, so the gap would have an increasing effect on velocity (because the bullet stays in the barrel longer so the gap will bleed off more gas).

The only explanation I can come up with is because they were using handgun, not rifle, cartridges (.38 Special & .357 Magnum), once the pressure inside the barrel decreased to a certain level the friction from the barrel begins to have a much greater impact on the velocity than the bleeding of gas, thereby decreasing the relative impact of the cylinder gap. Can anyone else come up with any other explanations?

Your Privacy Choices

Your Privacy Choices