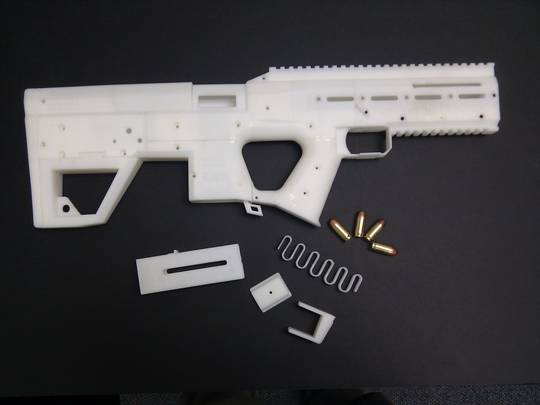

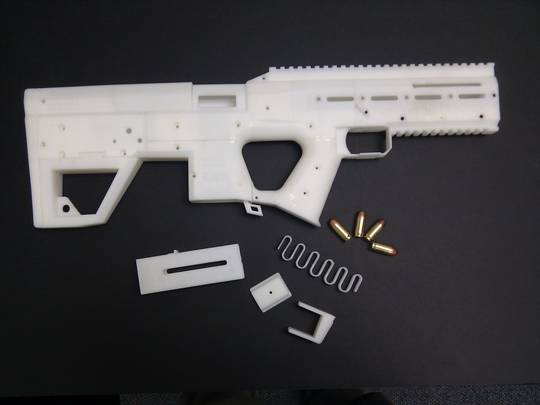

Strike Industries emailed me photos of a futuristic .45 ACP submachine gun that Sam, their engineer, printed out on their rapid prototyping machine. Its a very nifty design.

Prototyping a .45 SMG

Strike Industries emailed me photos of a futuristic .45 ACP submachine gun that Sam, their engineer, printed out on their rapid prototyping machine. Its a very nifty design.