The fact that guns get dirty is is one of those unfortunate facts of life, along with death and taxes.

A piston operated gun will reduce the dirt that enters the rifle compared to a direct gas impingement gun (AR-15). When you add a suppressor, I think it makes little difference what type of gas system your rifle uses, it is going to get very dirty!

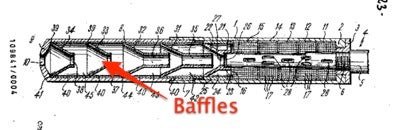

From the patent of an early model MP5SD suppressor.

A suppressor works by slowing down the gas through a series of baffles. The slower moving gas makes less noise as it is vented out of the can (can = slang for suppressor). The downside is that on a autoloading firearm once the action cycles and the spent cartridge is ejected there is more pressurize gas in the system than there would be without a suppressor. This gas, along with carbon, dirt, unburned power, is vented into the rifle action. Without a suppressor this still happens but the pressure inside the barrel is lower because the gas is vented faster.

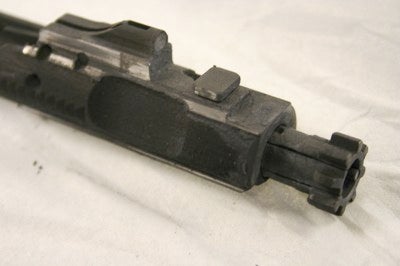

“new-arguy” posted photos at AR15.com of his HK 416 upper (piston AR-15 upper), which had a AAC 416 suppressor attached, after firing 2000 rounds without cleaning.

This is my HK 416 upper, I ran it with an AAC 416 silencer at the last Magpul Dynamics class here in St Augustine. 2 days, 2000 rounds. I only took the silencer off the start of day 2 for a few drills, I would guess about 150 rounds. All the rest were with the can. I dropped some lube in the gun at the start of the class, aside from that, no cleaning, no oil, nothing at all. No problems either, well, not really. I will admit, I have run regular DI guns like this without problems, but I needed to keep dumping oil on the bolt group. In fact, one of the guys who works with me ran his Noveske N4 with a AAC M4 2000 right next to me the whole class. His gun ran fine as well, but he did keep dumping lube into the bolt carrier.

Anyway, the gun was fiilthy. I have never cleaned a gun that was so dirty. Grime and crud was seeping out between the upper and lower trying to escape. It is worth mention that a large piece of carbon built up and fell under my trigger group toward the end of the second night. I thought it was a primer, but when I opened the gun up and shoot the lower, it was plainly a piece of carbon. So technically, the gun did comletely fail. I have seen this same thing happen one other time, in another Magpul class (actually the one from the last DVD). My friend Derek was running a gun with a can on it for about as many rounds. Same thing, crud kept building up until some of it found its way under the trigger group.

bigbore, of adcofirearms.com, posted photos of his AK-74 rifle after firing 2000 rounds of corrosive ammunition using a suppressor and leaving it sit for a week.

After leaving it sit for a week, the bolt rusted into place and it was no more than a club.

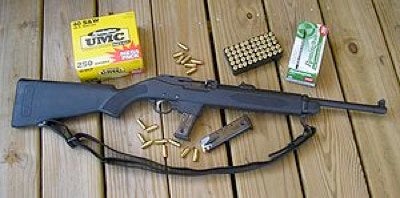

A problem with some of the now discontinued Ruger Police Carbine and Marlin Deer Camp, blowback autoloader pistol caliber carbines, was that their actions got very dirty. A pistol in the same caliber with a 4″ barrel would vent gas much faster than a 16.5″ barreled carbine.

Ruger PC4 (Police Carbine .40 S&W).

There is no substitute for cleaning your rifle. If you are considering a suppressor this is something to take into account. Bolt/lever/single shot action rifle with suppressors will not have this problem. The gas will be vented before the action is manually cycled. I personally have not had any problems with .22 semi-autos rifles with suppressors, nor have I heard of anyone having problems.

Many thanks to Jay for emailing me the link to the photos.

Your Privacy Choices

Your Privacy Choices