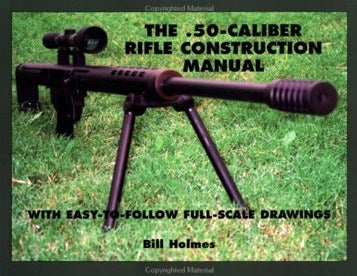

The .50-Caliber Rifle Construction Manual written by Bill Holmes was published in 2002. The Amazon customer reviews have criticized the book for its poor drawings and complex construction techniques.

A guy names “mxwelch” on YouTube has build a working .50 BMG rifle based on Bill’s book. To simplify construction he used an M2 maching gun barrel which he cut it down and re-chambered, instead of building his own, and made the rifle single shot instead of a magazine fed repeater.

The total monetary cost was $400 which includes the M2 barrel and chamber reamer rental. It took over 25 hours of shop time to build!

It weights 34 lbs and can shoot 1.5 MOA.

Your Privacy Choices

Your Privacy Choices