Earlier this year the Turkish Ministry of Defense announced they will be switching from the G3 7.62mm rifle to the HK416. The Turkish government owned arms and ordnance manufacturer MKEK will be producing the rifle under license from Heckler & Koch.

The H&K G3 battle rifle has been phased out in many countries and replaced with assault rifles chambered in intermediate cartridges. Along with the H&K G3, MKEK also produces the a variety of H&K MP5 models so the move to another H&K rifle is not surprising. Norway is also replacing the G3 with the HK416.

An important Turkish guy holding the Mehmetçik-1.Photo from worldaffairsboard.com

The pistol grip and stock look different to most of the HK416 photos on the internet. The wikipedia page has a photo with “HK416N” markings and the same configuration. The photo is marked for deletion from Wikipedia and there are few other references to the “HK416N” on google.

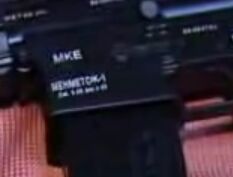

HK416N markings. Photo from Wikipedia.

Mehmetçik-1 markings

I cannot see any other differences between the Mehmetçik-1 and the HK416N other than the MKEK markings. The only different I have read about on a couple of forums is that MKEK are using different manufacturing techniques and different metals than H&K, which I take to mean a slightly different aluminum and steel alloys, which is not surprising.

The scope pictured above is the Elcan SpecterOS34x scope which well known for its use on the Canadian Diemaco C7/C8. The grenade launcher is the H&K AG416.

The Turkish Wikipedia page says the rifle will be manufactured in four different models. A Sub-carbine (10.5″ barrel), Carbine (14.5″ barrel), Rifle (16.5″ barrel) and “Distance” (Sniper/Marksmen, 20″ barrel).

Below is a video of a press conference with that important Turkish guy showing off the weapons and looking out of his depth:

By all accounts the HK416 is a great rifle combining the best of the AR-15 platform with the benefits of a gas piston system.

Turkey has also adopted a new sniper rifle that I cannot identify. Anyone know what it is? See the below photo.

UPDATE: Alcibiades, correctly identified it as the 7.62x51mm JNG 90, also made by MKEK.

Mehmetçik-1 and JNG 90 sniper rifle. Photo from worldaffairsboard.com

Hat Tip: GunPundit

Your Privacy Choices

Your Privacy Choices