Ronnie Barrett stands among legends like John Browning, Eugene Stoner, and John Garand as one of only a handful of Americans to have their rifle adopted by the United States Military. For over 40 years Barrett Firearms has been and continues to be, the leader in long-range. At SHOT Show 2023, I was given the opportunity to interview the new owner of Barrett Firearms, Robert Nioa.

At the conclusion of this interview, I asked Barrett’s senior staff if Ronnie would be willing to share the unabridged story of Barrett Firearms. He politely said yes, and asked when and where I’d like to do the interview. Not wanting to waste his valuable time, I told him when and wherever he’d like. Well, both Barrett conference rooms were already in use, so we quietly snuck into a small supply closet (a very fitting place for this story to be told). From there, the story began.

The History: The Story of Barrett Firearms with Ronnie Barrett

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

TFB (Austin R.): I’m here with Ronnie, Ronnie Barrett, the man himself. And congrats on the 40-year anniversary.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Ronnie Barrett: Thank you. It’s unbelievable. 40 years from starting in a little garage.

I was born a gunman. I think that there are certain people that are just born gunmen or a musician or whatever their talent is. When I was around 10 years old, my brother and I would ride our bicycles down a little dirt road out behind our house carrying our BB guns. We’d shoot birds, tin cans, or whatever we could find, any target of opportunity. Later we progressed up to 22 rifles. Next, my dad bought us a 20-gauge shotgun that we had to share. If you can imagine that, sharing anything with your brother.

My Dad was very insistent on us working, so from whatever age I could hold a broom and couldn’t get out of it, I was working at Pops cabinet shop.

My last two years of high school I was enrolled in the art class. A very successful photography studio would yearly contact the art teacher looking for the best student to offer them a seasonal job as a retouching artist. I got the job. It was the only real job I ever had for a few months, working at the photography studio as a retouching artist. After hours, I would accompany one of the photographers on any assignment he had. I very quickly picked up how parts of the business worked. I was devastated to learn my job was only seasonal.

With school coming to an end, I started my own photography business. I set up a camera room in my parent’s garage. The business did well enough, it gave me just enough money at just the right time when I needed it.

It was 1972, I turned 18. In a few months, the draft was ended and the age of adulthood changed to 18 years old. The first thing I did was bought a .45 ACP Colt Series 70 model pistol.

I then found a building downtown that I could rent, I could come up with the rent if the landlord would let me pay at the end of the month, and she did! The building was 20 feet wide at the front and 100 feet long. To a gun guy, that means the hallway running down of my photography studio was a straight-line shot. I went over to my dad’s cabinet shop and made a plywood box with a target area and mounted a steel plate behind it at a 45-degree angle. Below the plate was six inches of sand in the bottom. If all went well, we’d shoot the angled steel plate and the bullets would splat down into the sand. I made sure to put it below the electrical panel at the end of the hallway. Fortunately, one door up the street was the new police department building. Their shooting range hadn’t been finished yet.

Many a night, some of the patrolmen would come down to my place and we’d open both the front and back doors of the studio, to let the gun smoke vent out. Then sweep the unburned gunpowder up at the end of the night. Yes, shooting at Barrett Studio in downtown Murfreesboro Tennessee, what a blast!

My three brothers and I shot nearly every weekend. Everyone would bring everything we had and shoot until the ammo was out. Soon I was buying more handguns, several long rifles, all tactical, hunting firearms didn’t hold my interest.

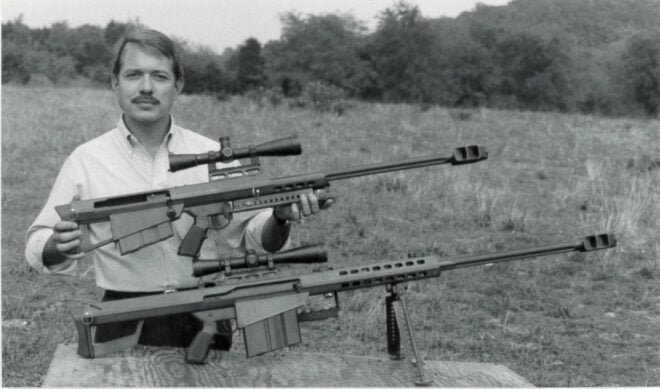

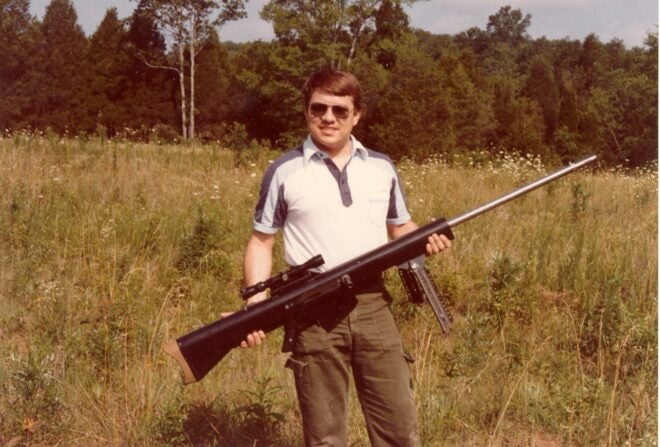

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

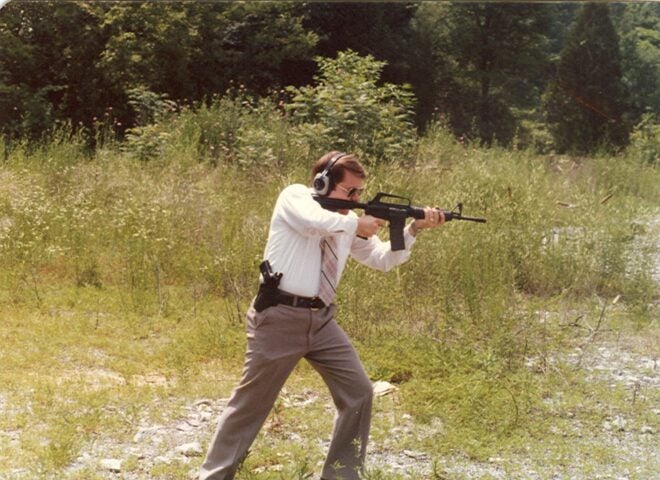

I bought my first AR 15 back then, and I still have it. During this time you could convert semi-automatic weapons into full auto. So, my first AR and a couple of Uzis got converted into full auto. There were sponsored machine gun matches in middle Tennessee and I was into it!

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

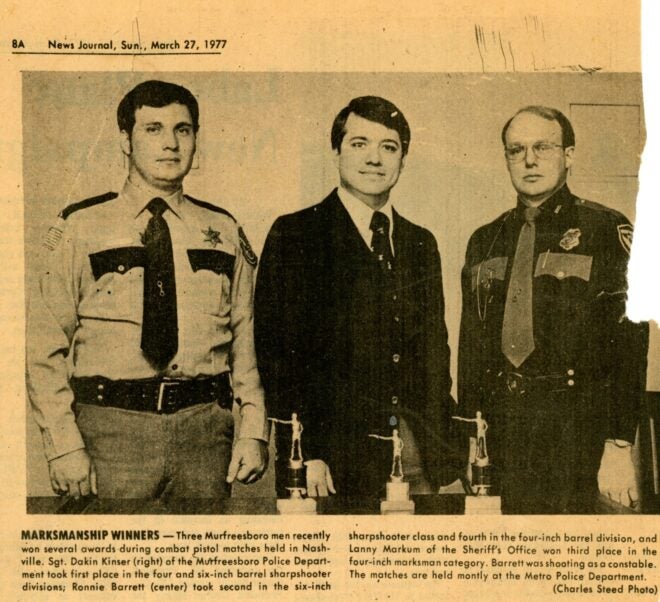

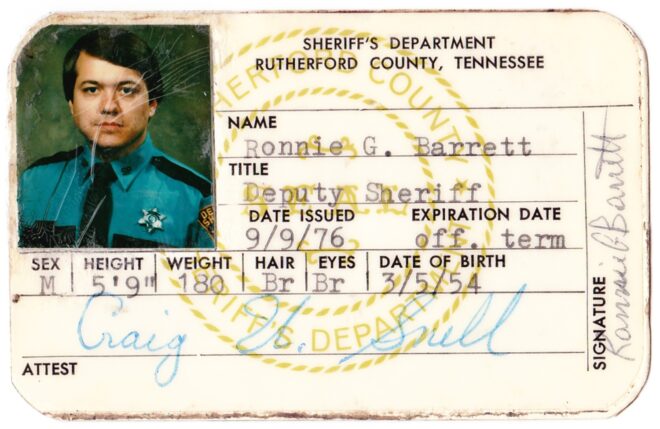

The Nashville Police Dept had some real good PPC matches for the local law enforcement. Our county’s Sherriff was a friend and commissioned me as a reserve deputy sheriff.

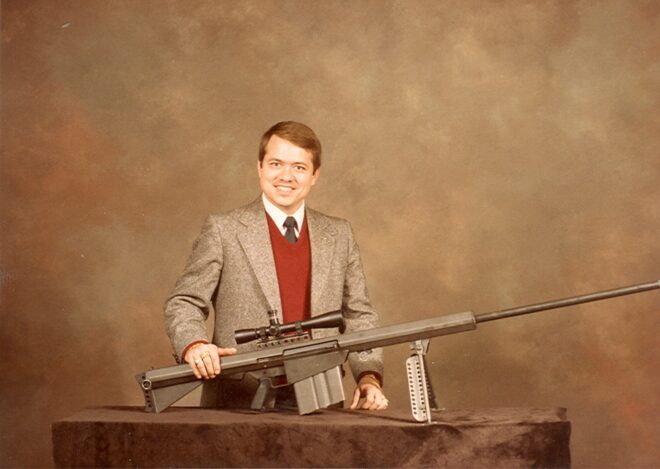

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Now, I was able to compete in those PPC matches. I even won one of the NRA regional championships. I was doing pretty good. I prided myself that I used a stock 6-inch barrel Colt Python while everyone else had highly custom revolvers that really wouldn’t function as a duty gun at all.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Seems like gun people somehow begin to know each other. One of those was E.R. (Pony) Maples. He too was a creative guy and with an amazing story. He restarted the manufacturing of the .50 caliber M2 machine gun. No one had built new receivers since World War II. The old stock from the war was running out. Pony had built a couple M2s out of component parts to put on some half-tracks he was restoring. From building a couple, it turned into Ramo Manufacturing in Nashville, a small business making new .50 cal M2HB machine guns. Pony and I became friends.

Ramo and Boston Whaler (a boat manufacturer) were prototyping a riverine patrol watercraft. On January 1, 1982, they had put the patrol boat on the Percy Priest Lake, (between Murfreesboro and Nashville) for a photo shoot. The photographer didn’t show up.

Pony called me at home and said, “I’m in bad shape. I’ve got a boat we’re putting in the water right now. Could you come down and photograph it for us?“. I said yes, got all my equipment, and arrived on the scene.

There, mounted on the Boston Whaler, were these two beautiful .50 Browning Machine Guns, glistening in the sunlight. If performance matters, if bigger really is better, then John Browning’s .50 is the champion.

In a quiet moment, I told Pony, “I always wanted a .50. I’ve been thinking about making a T bolt type action, straight pull of the bolt.”

Pony said, “Yeah, that would be nice. But if anybody ever made a semi-automatic, that would really be something.”

That was a new challenge, I said, “How about I make one, bring it to you and if you like it, we’ll make a few?”

What do you tell a 27-year-old kid like that? Pony said, “Sure, that’d be fine.”

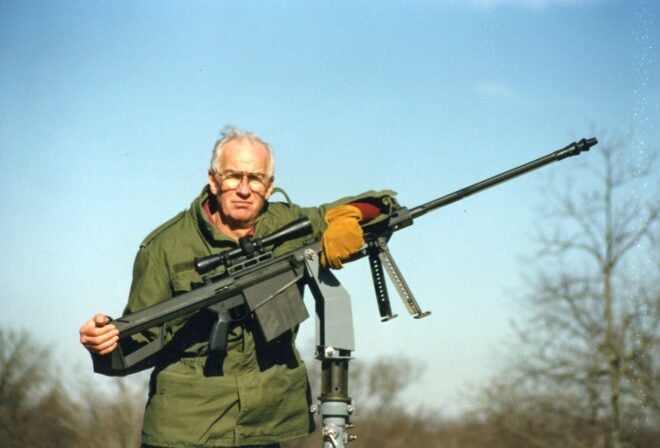

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pictured Above: E.R. “Pony” Maples

This kind of talk may sound strange, but I’m one of those guys that could do just about anything with my hands, retouching artist, photographer, woodwork, whatever. Probably youthful overconfidence, but I hadn’t found much I couldn’t do. It never struck me that I couldn’t. I have found there are a lot of these type of people. It is their gift.

OK back on track. Off I went on the project. At the local newspaper, I knew I could get the throw-away end roll of paper that had lot of paper left on the roll, I got one. At my dining room table, I rolled out seven feet or so, and with a tape measure and 12-inch ruler, I began drawing the rifle at full size. First, the hole in the barrel, then building around that hole. Next on an artist spiral pad, I drew the individual parts; one page one part. Not having any drafting experience, all my sketches were of the part, top to bottom, side view, angled view, just as I would roll it around in my head. All the dimensions were what I would have used in the cabinet shop, all in fractions.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

When I took my pad around to some of the machine shops, I got the reality awakening. They said, “This isn’t a print, it is an artist sketch.”

I drew it up in 3D as I saw it twirling around in my mind. One machinist was polite and explained “As an example, you’ll have to convert all these 1”1/4’s into 1.250” and then note if you will allow a plus or minus on how many thousandths can you accept when I make these? “

I said, “You just can’t make it inch and a quarter?” He said, “No, I mean, you know, it costs a lot of money to hold exactly an inch and a quarter. You got to tell me, do I have five thousandths one way or plus or minus ten? “

These were things I had no idea what he was talking about. This was a whole new world from the cabinet shop. I wish I had paid a little closer attention in high school; not sure if it was even taught! I found a friend to help me convert all the dimensions to decimals and then I got a crash course in what a set of calipers are and how all that works.

If that wasn’t bad enough, I quickly learned about different steels and hardness levels. Plus, I was blending sheet steel then welding it to components machined from bar stock, trying to stress-relieve the weld without killing the hardness in both!

Now let’s do springs. How many pounds did you want? What kind of spring rate? All of this was coming in through trial and error. But even with no engineering experience at all, in two months I had drawn up what would become the first rifle. The thicknesses of the steel, how much here or there, it just kinda looked right to me!

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Finally, there was relief. My father-in-law spoke to his friend Bob Mitchell in Smyrna, a twenty-minute drive from my house. Bob had worked for Greer Stop Nut and Bolt and knew his business. He agreed to help me. In his back yard, he had a little garage shop no bigger than ten by twenty feet. It had a homemade wooden table, a small mill, (which I bought and still have), a little small lathe and a grinder to sharpen his tools.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

I’d close the studio at 5:00 pm, go to Bob’s, be there by six, and if I could keep him or his son Rick working till 10:00 pm, that was great. One time I coached him on until two in the morning! Any amount of time he’d give me, I would stay and get it done.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

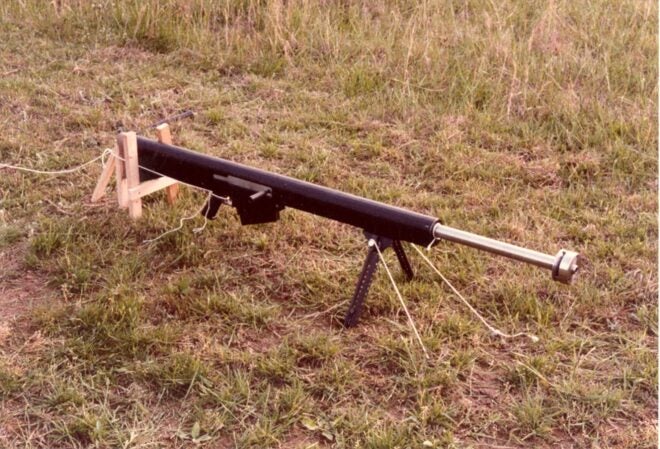

In four months, we had the first rifle. I had drawn it up in two months, had it made in four months, and it would shoot semi-reliably. It malfunctioned a lot; there were a few things to be discovered. Before the first prototype was finished, I had started on the second, lighter weight sexier looking, and easier to manufacture.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

I had started from big steel bar stock and machining it all away, but I still ended up with a 50-pound rifle. On the second prototype, it came to me, everything I was trying to do could fit within two inches. I discovered that I could buy steel in two-inch Hex bar shape and that resulted in the shape that you see the rifles have now. I mean, if only I had trademarked that Hex shape, so many rifles, and hand guards picked up on that look. It all originated from me being able to use the Hex bar stock. I used it as the inside front and rear barrel stops and the bolt carrier for the original 82.

The History: The Story of Barrett Firearms with Ronnie Barrett

I had already started on my second prototype. I took it over to E.R. Maples. Ramo was in the middle of bidding on the MK19 40mm grenade launcher. They were spending lots of money to make shooting submissions.

Pony said, “If we win this, we’ll have plenty of money, and we’ll be able to advance on your project. If we lose this, we’ll be in not so good of shape.” Well, they didn’t get it. That left me with my two prototypes; my first prototype and the second that I had only started.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

I was down over the missed opportunity with Ramo but still encouraged enough to continue building. I finished my second prototype and discovered a lot more improvements. I desperately needed to start on a third rifle using a stronger higher carbon sheet steel. During 1975 to 1982, I had only saved up $15,000 and it was now gone. I was told by my friend Dwight Hancock to approach my high school classmate and friend Tommy Vance. He had done well at one of the banks in town. I explained to him of my plan to build 30 of these rifles.

At least, now with a rifle to see and hold, some of the machining businesses would talk with me. I asked each what they estimated for the production cost to build something like this? They guessed, probably $1,000. Well, I wanted to make $1000 on each, but what if I missed it and they cost more? I’ll add an extra $300 for a little fudge factor.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

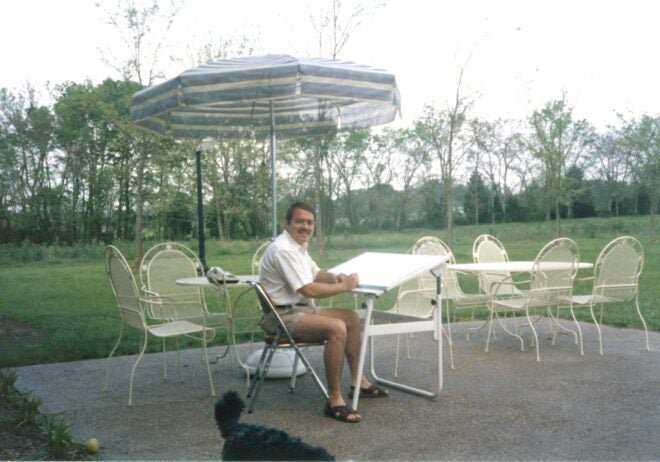

I took a full-page ad out in Shotgun News offering the rifle for $2,300. I took a picture of the second prototype (which was not finished yet) with one of my shooting buddies in a uniform holding it. And believe it or not, I got orders for it!

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

I hitched a ride in the Ramo van, to a large gun show in Houston, Texas. I displayed rifle #3 with a wooden stick behind the bolt carrier to hold it shut. I played a video that we had made showing off the first large prototype shooting. I received $300 deposits for three rifles. I had yet to figure out a place to build these things; no problem, I had a couple of months to figure it out!

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Harry Watson, a red-haired Scotsman, worked at a local fabricator that bent and welded the sheet metal of my prototypes. Harry had advised me that it wouldn’t be affordable to continue to build the receivers there as their company was not into production type of work; but if I were to set up a small TIG welder somewhere, he would come over after hours and weld them for me.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pop always kept his eyes open for old houses he and his two older boys could fix up. The one on Vine Street was built in the thirties. A fire had burned a hole through the center all the way out of the ceiling. We had worked on it through my high school days. Knowing I was getting married in 1975, I pushed to finish up the upstairs first then the downstairs and rented it. There was a pole barn/garage in the backyard. It had a gravel floor and no doors. It was 1982, and if I could convince Murfreesboro Electric Department to install a 220-volt service meter on this barn, this would become my manufacturing building! Unbelievably, I did and they did!

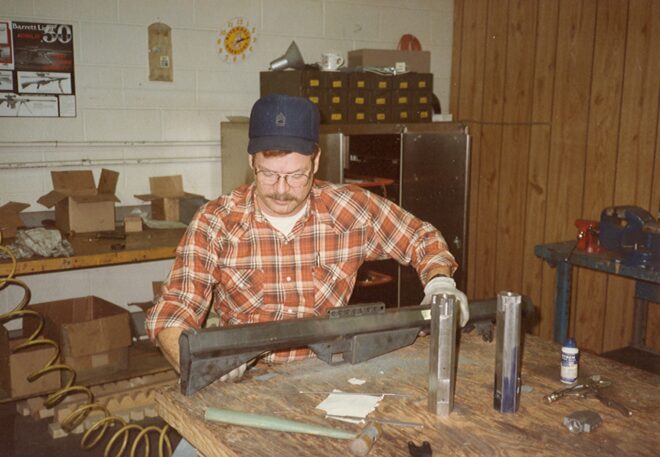

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Next, back to my dad’s cabinet shop. I made two doors that would close the front of the building. I used a purple carpet and turned the carpet upside down to cover the gravel floor so we didn’t lose any small parts in the rocks. Back to the cabinet shop to build a sturdy worktable and a couple of rolling racks that would hold 15 rifles. When I started with an eight-foot piece of plywood and divided it out using the width of the rifles, it came up to 15 rifles on the rack. I used these style racks for years. Harry would come over after work as promised and welded things together, all along teaching me how to weld.

I took orders for the first 30 rifles; it took more time than I had expected to build, like nine months. I really overestimated what I could do. I was getting a lot of practice keeping my customers to stick with me, but they did. With my attention only into building the rifles, I paid little attention to cost. Without any tracking of this, I didn’t know how much things were actually costing, but I was out of money.

I went back to my banker friend Tommy and convinced him to loan me another $30,000. This time I believed it would work out, I had improved the technique, bought some permanent tooling, and was confident. I raised the price to $3,700. I sold those quickly. I built them a little faster but still sunk deeper into more debt.

After getting some accounting people to see what I had done to get into this mess, It was discovered the first guns sold for $2,300 but actually cost me $8,000. The second ones sold for $3,700 and cost me $6,000.

It was obvious the price point really needed to be higher. I learned the importance; that several departments were needed to work together as a team. No more charging ahead blindly. I put the price up there, continued to reduce the cost on each batch, and started making a living on it.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Each place I would show or demonstrate the rifle, I endured the constant “What kind of squirrel do you shoot with that?” joke, it was sickening. I needed to convince people that there’s a role for a rifle like this.

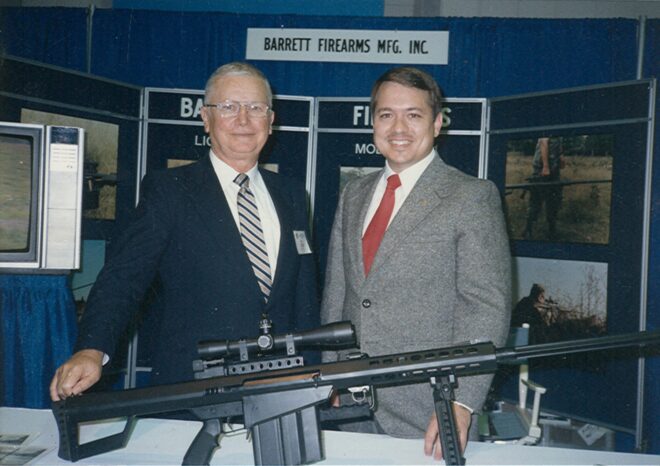

Dick Swan owner of Atlantic Research Marketing (ARMS) had the solution. Dick invented many of the great ways of mounting and interfacing devices on top of rifles. Dick told me about the Association of the United States Army that holds its meetings in Washington, DC. They have an exhibit hall, much like the SHOT Show. 10 x 10-foot Spaces were $16,000. I didn’t have that kind of money. Regardless, He said he had a way that might get me on the exhibit floor. I loaded up my photography studio van and headed to Washington DC. This was somewhere around 1983 or 1984.

The plan was to be at one of the hospitality suites. In those days the parties or the bar at the Marriott was the place to meet and greet. This night we walked into the hotel with a cased rifle, straight to the packed elevators, and into one of the hospitality suites. This experience was incredible as many times the packed elevator doors would open on a floor and the hallway was so packed with people you couldn’t get off, you had to go to the next floor and try your luck. Dick had spoken to one of the night vision manufacturers; they agreed to see the rifle in their suite. I got to the right room and set up the rifle on the coffee table. This, of course, gathered the room’s attention. I met with the contact person Dick had arranged and talked about how their night vision was large. “It’s huge. I’ve got this .50 here and if you put your night vision on this, the night vision will look a lot smaller.” We mounted one of the units on the rifle and let people view out from the balcony. It was a hit!

The next day, the rifle and night vision were on display in their booth. I leaned a little bit more and got him to let me put my brochures on the table. That’s what went down. Thank goodness! My first AUSA show, I was displaying there at no cost to me.

By the next year of the AUSA, I had four rifles spread around the exhibit hall.

By this time Barrett Firearms Manufacturing Inc. had a couple of employees, and we again packed in the Studio van for the 13-hour drive. We checked into a room at the Holiday Inn at Telegraph Road south of DC. I could only afford one room for all of us; it had two beds. My two employees each took a bed, and I slept on the floor.

Behind the hotel was a large parking lot that had a subway station. Each morning we’d get on the subway and ride uptown to the Marriott on Connecticut Avenue where the AUSA meeting was held. Everybody who had a real army was at the AUSA.

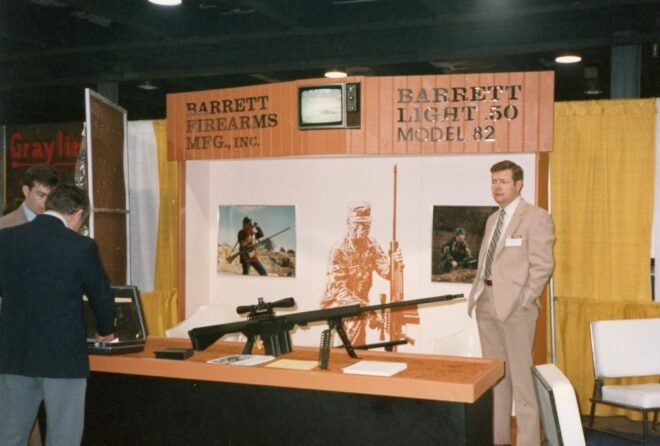

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

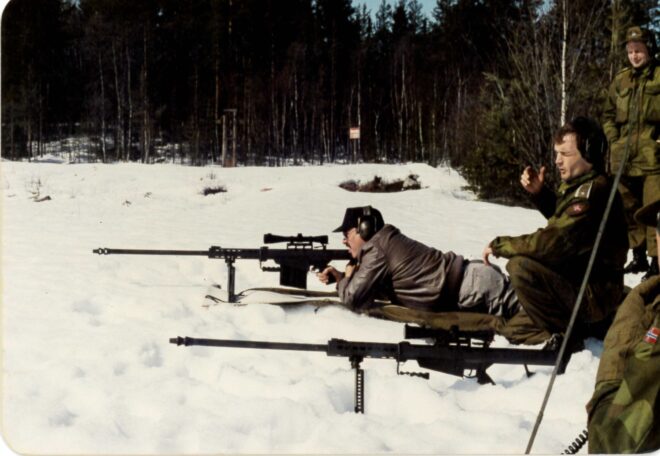

It was one little progress after the next one. Norway and Sweden were very interested and things looked like they would buy 100 rifles each. Then the Soviet Union fell apart, temporarily reducing their threat. Norway lost their budgets during that time. Sweden ended up placing my first real order.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

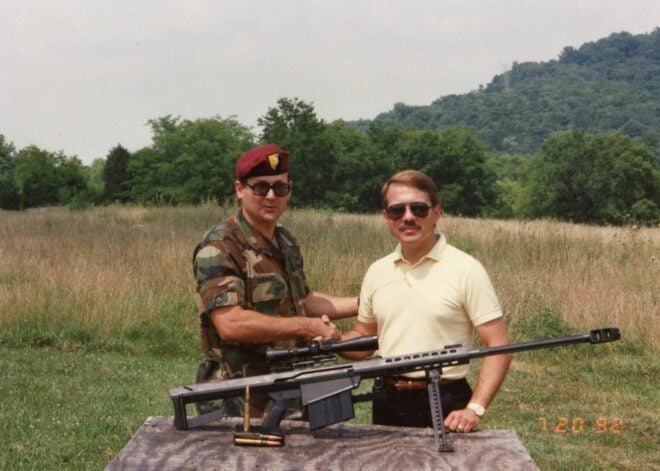

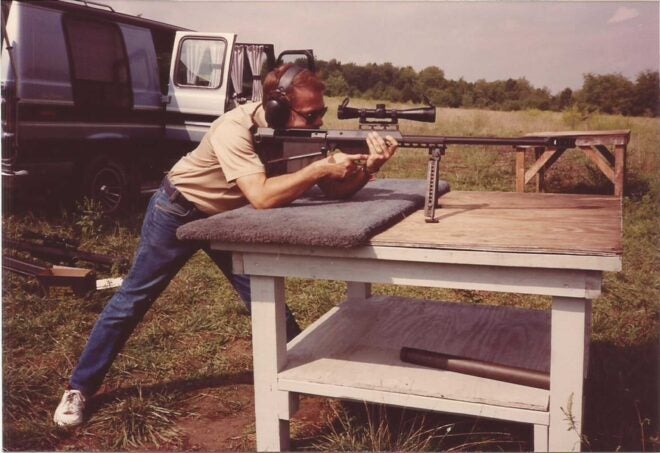

All along, I continued showing the rifle to the U.S. Marines, Army, Air Force, and Navy. We’d again, drive the photography van to Quantico, Fort Bragg, and Fort Campbell. One use I didn’t think of was at Eglin Air Force Base. The EOD people were testing the rifle to shoot unexploded ordinance at a safer distance.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

I’d go any place that would let me come and bring the rifle on base. Nowadays you’d be hard-pressed to do that because you just can’t bring a non-accepted or prototype firearm on base premises.

But we were doing it back in those years. Thank God we did, because Desert Storm was brewing and this rifle was going to be the perfect rifle for long-range distances found in the desert. At the Marine Corps Sniper School at Quantico, the scout snipers had been shooting their one rifle long enough to realize they needed more, and plans were in the making for more.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

In November 1990, I was holding 100 rifles for the Marine Corps. A call came from the United Kingdom, “We need some rifles right away, do you have any?”

I said, “Yes, I have 100 that I’m holding for the U.S. Marine Corps.”

He said, “Oh, look, you don’t know if they’re going to be able to come up with the money for that. I’ve got money now. I’ll take those hundred rifles today if you’ll sell them to me.”

I thought, he’s right, you know, you got to take the sure thing. So, I took the order, which left me with no rifles.

USMC Major Joe Kelly was to handle the procurement of carrying the urgent request to the commandant to sign off on buying 100 rifles.

Actually, it was supposed to be 200 rifles, but Kelly wasn’t sure if he could swing that much. At the last moment, he made it for 100 rifles. The commandant signed his approval!

So, in December, the Marine Corps placed their orders, I needed to have 100 rifles in Riyadh by January the 10th. That was just impossible, but I kept that to myself.

We started working at five in the morning and we’d work till 11:00 at night. We only had about ten guys at this point and we were just walking zombies. It was a rated contract that called all our subcontractors to perform as well. I recall on Christmas morning in my backyard just outside city limits, I had a dirt pile five feet high that I could shoot down into. The sub-contractor from Nashville that Magnaflux our barrels testing for cracks, stood back from me as I handheld a rifle, turned my face away and fired a proof round from the hip into the dirt 15 feet away, then dropped to the knee, pull the barrel out, stuck another one in, fire again – thirty times. He quickly drove them to Nashville, tested them, and got them back the same day. I was proud of everyone!

We had the rifles in Riyadh on January 10, 1991.

It was the right rifle at the right time for the long-range stuff. And it worked well in the desert.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Once the rifle became an official U.S. Marine Corps rifle, the other services could transfer their money over to the Marine Corps and purchase them under this emergency declaration and they did.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

But after things calmed a bit, the U.S. Army was required to conduct an official open competition of their own; USSOCOM joined in. All of the Barretts were to be turned in until that concluded. Reluctantly, some of the users turned their rifles in, while others didn’t.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

The Army started the M107 program somewhere around 1999/2000. Barrett submitted two versions of our Model 82A1; one with an aluminum upper receiver, and the other, the standard 82A1 steel upper. Barrett also submitted our Model 95, a small bullpup .50 bolt action rifle.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

To our surprise, the Model 95 was the winner. Of course, I liked the model 95 – short, lighter, a perception of a little more accuracy. But I had spent years showing how to put two to three rounds in the air on a target before the bad guy knew they were coming.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

USSOCOM, the Special Forces also threw a fit. They said, no, we need a semi-automatic rifle because these targets are not going to sit still as we engage them. They’re moving and we need to be able to quickly put three fast shots in something or five fast shots, and then bug out.

The debate caused two more years to go by. They restrengthened the M107 documents to have more rounds fired on target in a lesser time.

The History: The Story of Barrett Firearms with Ronnie Barrett – Barrett M107A1

The all-steel version of the Model 82A1 was adopted as the M107. In time, 75 other allied governments followed suit and now it’s in service around the world, thousands of them.

The History: The Story of Barrett Firearms with Ronnie Barrett – Barrett MRAD

It’s been a blast, but if you think this story is fantastic, what’s more unusual is a company like Barrett to have another unique design adopted – The Mark 22 /MRAD. This doesn’t happen often. What never happens and will probably never again, is my son Chris designed it!

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Chris and I were designing a semi-auto .338 caliber rifle in 1998 (that would be named Model 98). It was a very different semi-auto that would comply with the Crime bill weapons ban of the day.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

There arose a flurry of cheap single-shot .50 caliber “sort of rifles” popping up in the civilian market. Barrett had nothing that would compete. We put the Model 98 on hold while Chris designed the Model 99 single-shot rifle (in the year 1999).

The History: The Story of Barrett Firearms with Ronnie Barrett – Barrett M99

Starting with a hollow core aluminum extrusion, the barrel is inserted from the rear and held in place by a lock nut from the front. A real neat look, everything was fairly modular and, unlike the competition, was loaded without taking the rifle apart. It was and is very successful.

Once Chris got back on the .338 98 projects, The stupid crime bill had sunset. The brilliance of the simplicities of the Model 99 with the aluminum extrusion with a hole in the center influenced him more. The result was the beautiful 98B rifle. An incredibly accurate bolt action repeater that borrowed nothing from rifle designs of the past.

I remember him telling me ”Dad, all tactical rifles will look like this just as soon as we introduce this.”

It was not just an old deer rifle slicked up in a racy stock, it was ground-breaking.

The 98B was recognized in 2010 as the NRA Rifle of the Year Golden Bullseye Award. The Golden Bullseye award is a symbol of excellence and innovation in firearms.

The History: The Story of Barrett Firearms with Ronnie Barrett – Barrett MRAD

The precision sniper rifle contract competition came up in the U.S. Chris modified the 98B to have a folding stock and a quick-change barrel/caliber that came out the front of the receiver. This version was renamed MRAD. Not unlike the ups and downs with the M107 acquisition, the PSR had them too. The award went to someone else. But like the M107, there was more consideration taking place. There’s more to the story.

As the MRAD was being shot around the world, over and over, proving it is indeed the most accurate rifle in the world, it rapidly began being adopted by many allied governments. In 2012 the MRAD was also recognized with the Golden Bullseye Award.

The History: The Story of Barrett Firearms with Ronnie Barrett – Mark 22

Things were made right as the U.S. reopened the search now under the ASR program. When the dust settled in 2019, the MRAD as was adopted as the Mark 22.

The History: The Story of Barrett Firearms with Ronnie Barrett – Mark 22

And so now we’ve had a father who was the fourth person in the last 100 years to invent a RIFLE adopted by the United States. Chris Barrett became the fifth person in the last hundred years to have his RIFLE design adopted by the United States.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

To go through the official trials, the test, and then actually be adopted and pronounced a US rifle. That’s what we have. I think it’s the only time a father and a son both, had their rifles officially adopted by the US. We’ve made history in that it’ll probably never happen again. We’re just extremely proud of that. I thank God that we were allowed to participate in all of this.

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pictured Above: Barrett XM109 AMPR

TFB (Austin R.): This is all fascinating as one of the first articles I wrote for The Firearm Blog was on your XM109 AMPR. I mean, there are not too many platforms where you can scale it and say, “Hey, can we shoot 25-millimeter grenades out of this?”

Ronnie Barrett: Well if you’ll notice, on the bottom of every M107, and it may be on 107A1, the front hinge pin is relieved larger than needed in order to fit the larger 25-millimeter I.D. barrel. The 25 mm program may come back around, we will see.

The History: The Story of Barrett Firearms with Ronnie Barrett – M107A1 Font Hinge Pin

Now, what’s making news today is a really nice private company called NIOA has just acquired Barrett.

Rob Nioa and his wife Eliza run a family business in our industry. Barrett and NIOA have worked together on different projects for over ten years. We’re both privately held family businesses. I’ll be turning 69 in March. I’ve been in the gun business for 40 years, 50 years total with the Barrett Studio, which transformed into Barrett Firearms Manufacturing Inc. It was time.

NIOA Group CEO Robert Nioa poses with a Barrett (NIOA)

My son Chris and I are both still there as advisors. The plant stays just the way it is. All the same, employees are there. The same stuff that you come to expect out of Barrett will not be interrupted.

We’re just pleased as punch that we’re becoming a part of the Nioa family of businesses. It’s going to be good. The future is very bright.

TFB (Austin R.): I look forward to it. Thank you so much for taking the time. I can hopefully get a photo with you really quick.

The History: The Story of Barrett Firearms with Ronnie Barrett

Special thank you to Barrett staff for providing the archive photos for this article, and a very special thank you to the man himself for taking the time to tell this story in its entirety. Below are some extra photos courtesy of Barrett Firearms Manufacturing. Thanks for reading.

Bonus Photos

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pictured Above: Ronnie Barrett and Mikhail Kalashnikov

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pictured Above: Ronnie Barrett and Eugene Stoner

The History: The Story of Barrett Firearms with Ronnie Barrett — Photo Courtesy of Barrett Firearms

Pictured Above: Ronnie Barrett with Richard “Mack” Machowicz host of Future Weapons

Your Privacy Choices

Your Privacy Choices