Welcome everyone to the TFB Armorer’s Bench! As mentioned in the little blurb below, this series will focus on a lot of home armorer and gunsmith activities. In this article, I decided to run through another “commentary” style article since it seems they are well received and doing their job by being informative. This one is going to be centered around the Remington 74 series of semiautomatic hunting rifles. I use the term “74 series” to loosely encapsulate models of Remington rifles that share the same characteristics and similar issues. More so than anything, this article will address Model 740 and 742. Full disclosure: I am no fan of these two rifles or their “improved” later renditions.

With that in mind, I will refrain from being too terribly brutal in my opinions (maybe save them for the end) and present what I know, have witnessed, and experienced in regard to these firearms. This is not an article intending to attack a family hand-me-down rifle, a fond hunting companion, or a loveable range toy. The bottom line is these guns have known issues and have been and always will be a source of job security for the town gunsmith. Let’s dive right into this week’s commentary on the Remington 74 Series of Autoloading Rifles!

TFB Armorer’s Bench: The Remington 74 Series

Here, we at TFB hope to inform, entertain, and even inspire any would-be gunsmith or armorer out there. Ideally, with the information I provide and with the help of our sponsors, you can have some useful knowledge pertaining to the conservation and improvement of firearms technology while at the same time sharing experiences and teaching each other new tips and tricks along the way in the comments. Digging deep into what it is to be an armorer or gunsmith has significance but what is important is what those people do to show they’ve earned that title. I am happy to share my experiences and knowledge and hope it is informative!

Make your personal safety a priority:

- Practice proper gun safety. Always make sure before the firearm hits your bench that it is unloaded and safe to be handled.

- Wear the proper safety equipment. The main one would be safety glasses (decent ones) since parts are often under spring tension and you may work with high RPM tools. Other honorable mentions would be latex gloves or a respirator when working with potentially harmful solvents and oils. Also hearing protection when working with loud machinery or test-firing firearms.

- Modifications, alterations, and customizations will void your firearm’s warranty 9.5 times out of 10. Please take that into consideration before attempting any at-home gunsmithing.

- If you are unsure about proper safety practices, disassembly procedures, or warranty standards, stop, put down the tools, and consult a competent gunsmith.

Quick History: The Remington 74 Series

If memory serves, when John Moses Browning was working on, designing, or launching the Auto 5 Shotgun, he had asked various manufacturers if they were interested in a semiautomatic rifle. It may surprise you to know that most were not interested! With the success of the Auto 5 and the popularity of competing brands’ autoloading rifles, Remington took John Moses Browning up on his offer to sell/license his rifle design. Much like the Auto 5, it used a long recoil operating system to function and a very interesting safety selector (long before it was used on the AK platform). This rifle would become the Remington Model 8 and it was produced from 1906 until it was updated and replaced by the Model 81 in 1936. These rifles worked well and were popular but by the time they were discontinued in 1950 they had seen a dip in sales.

Remington Model 81. Photo credit: Rock Island Auction Company

Remington’s R&D team went to work and by 1956 they had a product to release to the world. This newest and coolest hunting implement was called the Remington 740. It was a gas-operated (similar concept as an M1 Garand) semi-automatic rifle chambered in various cartridges, fed by a four-round detachable box magazine, and it sported a semi-pistol grip walnut stock.

Remington 740. Photo credit: Rock Island Auction Company

The Model 740 had some issues and three years after its release, Remington “updated” the rifle and called it the Remington 742! These updates were not terribly significant but they did alleviate some issues and potentially presented some minor new ones. The way the forend was attached to the gun as well as the method/style of the barrel nut were changed. It went from a spanner style to a more flat-sided nut style. The 742 would have a much longer run (20 years) and boasted production numbers of around 1,500,000 (rough estimates from various sources). That includes the 740 just for fun. Toward the end of their production around 1980, Remington was seeing more and more issues pop up with 740 and 742 rifles but they also already had some fixes ready for the next generation (which admittedly had fewer problems).

Remington 742. Photo credit: Rock Island Auction Company

The Remington 7400 and Remington FOUR debuted in 1981 as the newly updated Remington rifle. They showed up together because the Model FOUR was the deluxe version of the 7400. The FOUR was discontinued in 1987 and a lot of its more premium features ended up on different grades of the 7400. The 7400 went on to be produced until 2005.

Remington 7400. Photo credit: Rock Island Auction Company

In the middle of all of that was the Model 74 (despite the title it is not the star of the show) which was the budget version of the 7400. It popped up in 1984 and was marketed as an overall everyman sort of rifle. It was intended that just about any hunter could afford to pick one up and support the Remington name. Much like the Model FOUR, its production ended in 1987 and its features bled into various grades of the 7400.

Remington FOUR. Photo credit: Rock Island Auction Company

The final lookalike in this family of Remington 74 rifles is…(drumroll) the Remington 750. Yes, a slightly different number but a very similar rifle in many ways. This was Remington’s final legitimate old-timey hunting rifle and it showed. They were made for ten years from 2006 until 2016. Their camo-ed-up AR rifles took up the hunting rifle slack for the remainder of that Remingtons run.

Remington 750. Photo credit: Rock Island Auction Company

I apologize for any vagueness or lack of in-depth details. I try to keep the “quick history” quick. I love researching this sort of stuff and I encourage you, folks, to do so as well if you enjoy the process. Now, onto the rough stuff!

Common Issues & Potential Reasons: The Remington 74 Series

Opening Disclaimer: These issues are exclusive to certain models. I will try to elaborate and recap which guns these pertain to.

Accuracy Issues: The Remington 740 is probably the most notorious for this. Much like on an AR15 (I realize this counts for all guns) if the handguard makes contact with the barrel then it will affect the barrel harmonics. The problem lies with how the handguard can be over-tightened very easily. During firing, those parts start to move and if you are looking for accuracy, it will mess with your barrel harmonics. This was remedied by an “accuracy block” made by Williams and later an in-line Remington change with their own series of spacers. It was a small aluminum cube with a hole drilled through it which would be placed inside the handguard. The forend screw would go into the handguard, through the accuracy block, and then into the lug under the barrel. Basically, the block prevented the handguard from being tightened and acted as a spacer. Pertinent Model Recap: This mainly pertains to the 740. All can be included because they were run-of-the-mill hunting rifles meant to do adequate groups for hunting.

Feeding Issues: This is more common with just about all of them. The magazines are mostly to blame beyond the typical ammunition pickiness or dirty gun issues. The magazine springs are notoriously weak and the ones that were not, apparently wore out quickly. I personally have seen magazines with literally broken springs. The ones made in recent memory by Remington for the aftermarket seemed to perform 50/50 in my observation. Some would work great in guns and some would not function at all. I have heard of people positioning their cartridges more forward or backward depending on their grain weight and type of bullet used in order to have more reliability. Aside from all of the spring-related issues, the original early magazines have thin and soft feed lips that are easily persuaded and damaged. Pertinent Model Recap: Potentially all of them.

Cycling Issues: Like any semiautomatic firearm, these were prone to cycling issues for various reasons – if they were dirty, unkept, mistreated, or the wrong ammunition was used. Despite all the small variables, there are two factors I can bring up. One, this is a gas-operated system and like all gas-operated systems, it is prone to carbon fouling buildup somewhere. The way the gas is vented to the action bar is by way of a gas nozzle (I made that part name up) which is sticking out of a gas block that hides a hole in the barrel. This nozzle very quickly becomes fouled up. I have had rifles come in for a cleaning after sighting a few shots in at the range and the nozzle is already extremely fouled.

Beyond the gas system becoming easily dirty, the other issue is the dust cover/ejection port cover which in most cases is plastic (very early ones were metal). These flimsy covers are not only prone to breakage but would also warp and catch on the inside of the receiver. This, big or small, would impede the action in its travel.

Extraction Issues: Extraction issues are yet another thing that has plagued these poor guns. The extractors in the 742 (specifically) I have heard were brittle and were changed. I have not witnessed or experienced that. More so I have experienced rusty chambers, stuck cases, and headspace issues. The main and most common problem here is that for whatever reason (unknown to me) the action seems to prematurely extract cases. This could be due to high-pressure ammunition, weak springs, or just a flawed design in general. Why is this so bad? As the cartridge is being pulled reward the case mouth is still spewing hot gas, burning powder, and unburnt powder in the chamber area. This not only makes this area dirty and fouled up but it also can promote rust if unattended to. Dirty or rusty, cases will begin to stick and fail to extract and in some extreme cases be completely stuck.

This can also cause headspace issues since the fouling or rust will create more material in the chamber area by making it tighter it will slowly force that cartridge to be chambered further and further out (until ideally, a safety interlock stops any out-of-battery discharges). Heavy rust cleaned out of this area may solve one issue and create another. That is material removed so you are making the area bigger. It is a double-edged sword and you may still end up with headspace-related issues. One last point of extraction note! I believe (I have no data to back this up beyond my observations) that toward the end of the 7400 rifles’ life span and the 750s as well, the premature extraction issue was remedied. Although, I had quite a few new-ish Remington 750 rifles come to my bench that had very visible burrs present in the chamber and feed throat area. Probably an obvious sign of what was to come of that Remington’s quality control issues.

Important Note: If you are concerned about the headspace of your personal rifle make sure to inspect your brass. Check for cracks at the neck, bulges at the base, and flattened primers.

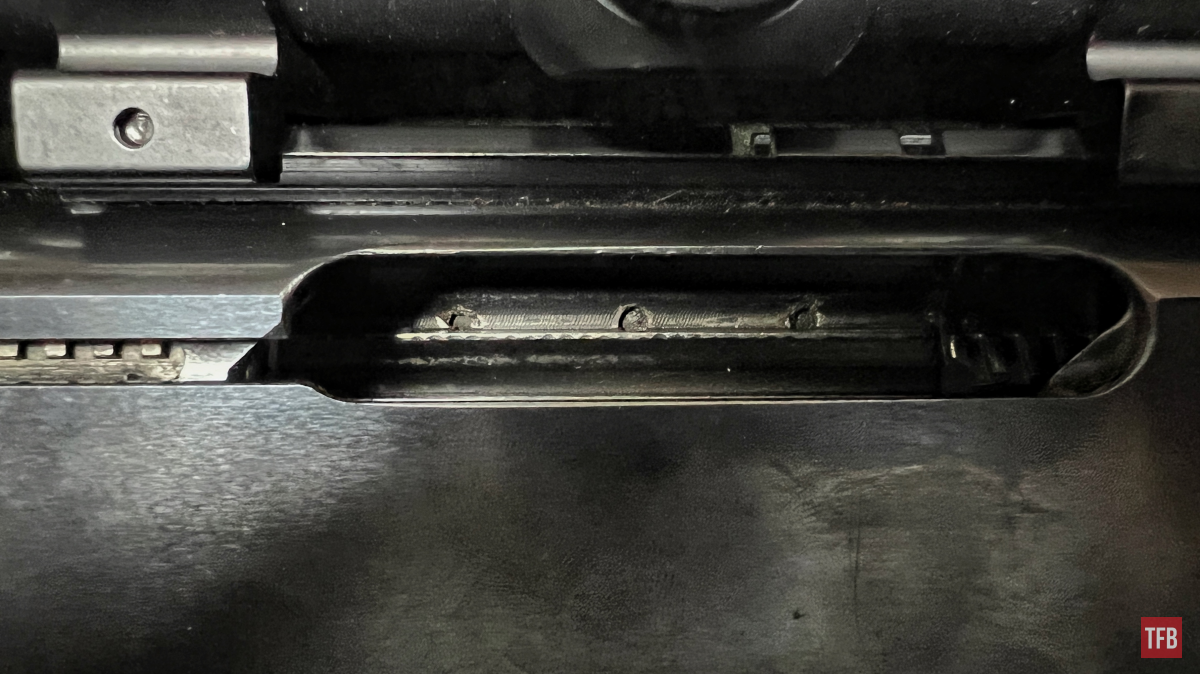

Greatest Issue: This is the granddaddy of these gun issues and it is exclusive to the Remington 740 and Remington 742. These guns were not robust in the least and the receivers are surprisingly soft. The bolts in these guns have five distinct locking lugs and over time these lugs will impact and carve/peen an image of themselves into the action rails towards the back of the receiver.

These will eventually get so deep that the bolt could literally lock into those marks and refuse to be persuaded forward. These rails will even bend in some cases by the damage inflicted repeatedly. This is most common in the bigger cartridges such as 30-06 but it is an ailment of all of these guns. I am sorry to say that they are more or less time bombs and will eventually beat themselves to disrepair. I have heard of and seen pictures of rare cases where the locking lugs in the barrel itself would sheer off by the force of the bolt flying forward after a particularly hot round. These may have been reloading, I am not sure.

These huge issues were finally addressed in the 7400 rifles and on. They now had bolts with three large locking lugs and a hardened rail insert that was placed in the top of the receiver to better guide the lug that would ride under it.

Closing Thoughts: The Remington 74 Series

I had been planning on addressing this series of rifles for some time. Mainly because it plain and simply is my nemesis, I despise these guns. If you have listened to any of the podcasts I have been on, Luke has made me bring it up both times if I remember right and I am playfully upset over these. I bear no judgment on anyone who owns or has owned or even enjoys theirs. This article was intended to showcase my experience and information transparently (I am sure there are more issues I forgot about). I know people that have had these guns their whole lives and never had an issue. I would bet anything that is because they only shoot them once or twice a year before going hunting.

Apparently, Remington Repair Centers offered a conversion that would turn their semiautomatic into one of their pumps (760/7600) if that was preferred or as a way of making up for the fact that they were not working. I have seen claims by former Remington Repair Center employees that these guns (more so the older bunch) had a 500-round lifespan before developing real-deal issues. As a gunsmith, I wholeheartedly believe that statement. In gunsmithing school, I remember being warned about them. I remember hearing “a lot of gunsmiths refuse to work on these” when talking about the 740 and 742. It is not because a gunsmith could not fix that rail issue I talked about earlier. It is because before too long another problem would pop up and then another and another and so on. It would be endless and the customer would accuse the gunsmith of not solving the issue or creating another one. Those peen marks can be filed down, welded, and or reshaped but they will, unfortunately, appear again before too long.

Back in the day, it seems like everyone had a permutation of these rifles. They did the job, were affordable, and in most cases well-liked. I wish they worked better and were not such a common item on the bench. I wish they were more fun to clean and disassemble. I wish there was more thought put into how an owner may clean the chamber. I believe the first of them was rushed to compete with the likes of Winchesters rifles and affordable surplus military rifles. I think it had a lot of potential and was designed well but executed very poorly in the name of getting a product out to compete RIGHT NOW. I hope this was an enjoyable and informative read. I apologize if any of it came across as unclear, it was written over days of remembering issues and so on. Thank you as always and I will see you next time!

As always, thank you for reading TFB! Be safe out there, have fun while shooting, and we will see you next time for the TFB Armorer’s Bench! Also, let us know what you think in the comments below! We always appreciate your feedback.

Your Privacy Choices

Your Privacy Choices