Welcome everyone to the TFB Armorer’s Bench! As mentioned in the little blurb below, this series will focus on a lot of home armorer and gunsmith activities. In this article, I decided to go over the process of polishing feed ramps. There are precautions and decisions that need to be made before attempting this sort of stuff. Most handguns do not need their feed ramp polished. That being said, this will cover pistol feed ramps only. In the future, if given the chance, I will go over polishing AR15 feed ramps. Let’s dive right into Polishing Feed Ramps!

TFB Armorer’s Bench: Polishing Feed Ramps

Here, we at TFB hope to inform, entertain, and even inspire any would-be gunsmith or armorer out there. Ideally, with the information I provide and with the help of our sponsors, you can have some useful knowledge pertaining to the conservation and improvement of firearms technology while at the same time sharing experiences and teaching each other new tips and tricks along the way in the comments. Digging deep into what it is to be an armorer or gunsmith has significance but what is important is what those people do to show they’ve earned that title. I am happy to share my experiences and knowledge and hope it is informative!

Make your personal safety a priority:

- Practice proper gun safety. Always make sure before the firearm hits your bench that it is unloaded and safe to be handled.

- Wear the proper safety equipment. The main one would be safety glasses (decent ones) since parts are often under spring tension and you may work with high RPM tools. Other honorable mentions would be latex gloves or a respirator when working with potentially harmful solvents and oils. Also hearing protection when working with loud machinery or test-firing firearms.

- Modifications, alterations, and customizations will void your firearm’s warranty 9.5 times out of 10. Please take that into consideration before attempting any at-home gunsmithing.

- If you are unsure about proper safety practices, disassembly procedures, or warranty standards, stop, put down the tools, and consult a competent gunsmith.

Be Careful and Mindful: Polishing Feed Ramps

Polishing feed ramps is a popular and easy “improvement” that can be done in order to aid in the reliable feeding of your firearm. Typically it is done to pistols with a dedicated feed ramp rather than a feed throat. Both can be polished but there are some considerations you should make before ever thinking of polishing anything.

- Is your firearm having feeding issues? This could be related to ammunition, magazines, the overall condition of a magazine, and the shape of the bullet being fed (hollow points, flat points, round noses, etc). It is rare that the feed ramp is the direct cause or solution to better feeding.

- Type of firearm: A lot of guns do not actually have a feed ramp or throat at all. If this is the case, it means that the ramp may be built into the magazines or the frame itself and function in a hidden sense. I do not recommend polishing or creating a ramp in these types of firearms. Beyond that, some guns like 1911-style pistols have both a feed ramp and throat which are made to be at angles that are integral to reliable feeding. Tampering with them may result in worse feeding than you started with.

When and Why Should You Polish?

If you are experiencing feeding issues and have exhausted all other possibilities as far as causes it may be time to look at your feed ramp. Most well-known brand name companies polish the ramps at the factory these days but this does not mean you will not end up with a Friday afternoon job out of a large batch. Whether it is polished or blued or in the white, some feed ramps will have visible machine marks. You will see this in older handguns especially because these extra steps were deemed unnecessary or a waste of money and time.

Note the machine marks on this Colt 1908 Pocket Hammerless

There may be machine marks so fine you can barely see them or not at all. Regardless their existence can potentially cause feeding issues because as the bullet is guided up the ramp those marks have edges that will grab at the bullet. As the gun gets more and more fouled up this can aggravate the issue further by collecting on these microscopic marks.

Note: All of that being said, in my professional opinion, if you are not having issues, then I recommend leaving it be. It gets repeated again and again in this series but this is altering your firearm and most companies will not cover it under warranty if something were to go awry. Consult a trusted gunsmith if you are interested in having a feed ramp polished.

The Process: Polishing Feed Ramps

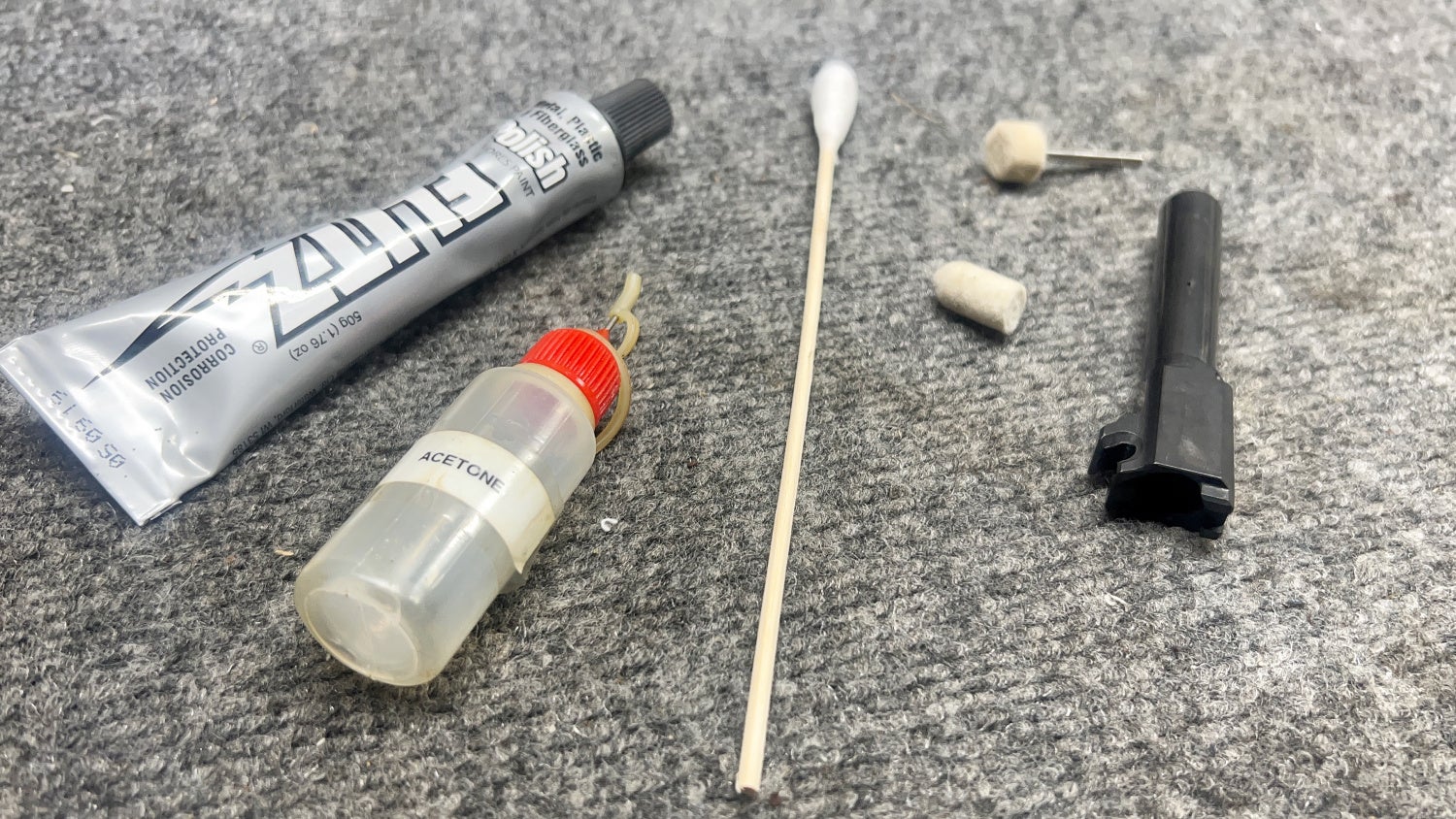

So what is polishing a feed ramp like? Does it involve a lot of expensive specialty tooling? No. For the most part, the cash investment is very minimal but it does involve time and patience. You can work with your materials by hand or by the dreaded Dremel. All you need is some metal polish and a Q-Tip or wool bit of some sort (such as one found in a Dremel kit). Acetone is a nice touch but an optional one.

Polishing Feed Ramps

The goal here is to polish. That is it. Not removing enough material to change angles. Not to round off straight edges that are meant to be there. This process is only to polish the surface of the feed ramp so it is like a mirror and knock down any machine marks or hidden abrasions we may not see.

Step One: Polishing Feed Ramps

The first thing is first! Safety. Yes, I know safety is boring and sooo mainstream but bear with me. Make sure your ammunition is stored and away from your bench. If starting out with an assembled firearm, make sure to check the chamber, magazine, and space between. Then check again. As far as PPE, I highly recommend wearing safety glasses at the very least. Your hands and fingers will get messy so if you feel the need to wear latex gloves I would not blame you.

Step Two: Polishing Feed Ramps

Starting out I like to clean the area of the workpiece that is being polished. This ramp was fouled up with carbon, to begin with, so I put a little bore cleaner on it for a minute and wiped it away with no problem. After cleaning the feed ramp area I will usually put some acetone on the ramp itself to degrease it. Is it 100% necessary? No, but I like to be extra mindful when working on something that will change in appearance. Degreasing gives me peace of mind that there is nothing present on the ramp that will impede proper polishing.

Polishing Feed Ramps

Step Three: Polishing Feed Ramps

The process from here is pretty simple. I put a nice glob of polishing paste onto the ramp and then I spin my cotton swab in it to properly coat it.

From here, using a back-and-forth motion mixed with spinning the cotton swab in your fingers, apply firm pressure to the ramp. Doing this exact step while adding any needed polishing paste/compound will get you a polished feed ramp. The downside is it will definitely take a while.

After about 20 minutes of some of the least productive hand cramping polishing I have ever done, you can see some hidden high spots reveal themselves. Odd this it was not so much the typical round machine marks but still case in point. Things may not be as perfect and smooth as they look and feel.

For pistols with finished barrels like this one, it may be difficult to remove that first layer of finish in general. That unfortunately was the case with this one so I did have to look to the dreaded Dremel for some rapidity.

Note: Some people who may not be so informed about the “gunsmithy ways” may be curious why I keep calling it “the dreaded Dremel”. This is mainly because the Dremel is a good tool for many applications but not so much so for gunsmithing. It is an aggressive shortcut tool that can often be a fickle mistress. The community will often joke about it and refer to it. For polishing sake, I will give it a pass so long as it is done with a careful and weary hand.

After another 30 minutes of the same back-and-forth motion with the Dremel and a cotton swab plugged into it (yep, I used a swab instead of a bit, cotton seemed to work better), I started to get that polish you should look for.

Another ten minutes were spent cleaning up the sides of the ramp where the swab missed or did not give enough attention.

Conclusion: Polishing Feed Ramps

After that, I was all set. I apologize for the low-luster pictures. It is hard to capture the reflection so I used a match head to reflect. From here I recommend giving the barrel cleaning in case any debris is lodged in it. Also, wipe down the outside with some protective oil to prevent rust. If you feel inclined, test feeding with dummy shells.

As always, thank you for reading TFB! Be safe out there, have fun while shooting, and we will see you next time for the TFB Armorer’s Bench! Also, let us know what you think in the comments below! We always appreciate your feedback.

Your Privacy Choices

Your Privacy Choices