Welcome everyone to the TFB Armorer’s Bench! As mentioned in the little blurb, this series will focus on a lot of home armorer and gunsmith activities. In this article sponsored by Wheeler, Tipton, Caldwell, and Frankford Arsenal, I decided it would be a fun exercise to go through the maintenance portion of the Glock Armorer’s Manual and demonstrate or explain what they say in the book. I myself do not own a Glock so my TFB coworker and AllOutdoor editor Adam S loaned me his Glock to demonstrate on and he also got a free gun cleaning. Fair trade! Let’s dive right into Glock maintenance by the (Glock Armorer’s) book!

TFB Armorer’s Bench: Glock Maintenance

Welcome to our recurring series of Armorer’s Bench which is made possible and brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal who are our sponsors. Here, we at TFB hope to inform, entertain, and even inspire any would-be gunsmith or armorer out there. Ideally, with the information I provide and with the help of our sponsors, you can have some useful knowledge pertaining to the conservation and improvement of firearms technology while at the same time sharing experiences and teaching each other new tips and tricks along the way in the comments. Digging deep into what it is to be an armorer or gunsmith has significance but what is important is what those people do to show they’ve earned that title. I am happy to share my experiences and knowledge and hope it is informative!

Make your personal safety a priority:

- Practice proper gun safety. Always make sure before the firearm hits your bench that it is unloaded and safe to be handled.

- Wear the proper safety equipment. The main one would be safety glasses (decent ones) since parts are often under spring tension and you may work with high RPM tools. Other honorable mentions would be latex gloves or a respirator when working with potentially harmful solvents and oils. Also hearing protection when working with loud machinery or test-firing firearms.

- Modifications, alterations, and customizations will void your firearm’s warranty 9.5 times out of 10. Please take that into consideration before attempting any at-home gunsmithing.

- If you are unsure about proper safety practices, disassembly procedures, or warranty standards, stop, put down the tools, and consult a competent gunsmith.

By The Book? – Glock Maintenance

So, the book is a manual and the manual is a very procedural and sometimes somewhat vague set of well-organized instructions and information. You receive a Glock Armorer’s Manual when you go through and complete one of their Armorer Courses. In all honesty, I do not remember when my course was (probably a year or so ago). I remember it being a lot of recap from gunsmith school and a few small tips and tricks sprinkled in. I will not be typing out their instructions verbatim so if I miss anything or misinterpret something that is on me. These instructions are very straightforward and basic but may be helpful or informative.

Note: I have to assume that the Glock Owners Manual contains a very similar description in terms of Glock maintenance and how to clean your pistol.

The manual contains a lot of handy information for anyone who deals with or has the potential to deal with Glock handguns on a daily basis. Near the end, there are around three pages dedicated to Glock maintenance. Those pages begin with field stripping (not covered in this article), then cleaning, and end with lubrication.

Speaking of lubrication, the Glock Armorer’s Manual uses the word “lubricant” frequently when talking about cleaning. Like putting lubricant in the barrel to clean it and stuff like that. I have no doubt that Glock in its touted perfection is capable of being cleaned with lubricant but as a gunsmith, I do not recommend using literally and exclusively gun lubricant to clean your gun, especially the bore. I believe the people that wrote the manual were either using the word as a broad term or it potentially could even have to do with it being translated for different languages. Pure speculation on my part. My recommendation for cleaning your gun will always be some sort of solvent. Check out my article on gunsmithing liquids at the link here!

Side Note: Lubricant in the barrel has the potential to act as a barrel obstruction. Imagine the bullet traveling down the barrel and gathering a bead of liquid just next to its point. That liquid may leave with the bullet but if it has tike and enough pressure the fastest and easiest way for that liquid to move out of the way is to go around the bullet which will almost always bulge a barrel. In my time working at FN in their product service center, I saw many handguns come in as a result of this or similar issues. It is a thing to be careful of. Make sure to put a patch down your bore until it is clean and dry.

Cleaning – Glock Maintenance

Starting off pre-cleaning, the Glock Armorer’s Manual talks briefly about “Cleaning Supplies and Lubricants”. It is mostly a liability paragraph discussing things like making sure your oils and solvents are meant for guns and to use them properly. One bit of information that they close with is “After cleaning, Glock pistols require a minimum of lubrication”. Besides the obvious reputation of Glock pistols being tanks, this can be twisted in a teaching manner. The more excess lubricant (or leftover solvent for that matter), the more your gun will foul up from carbon and lead attaching itself to the oils, greases, and liquids in general.

Barrel: With a “wet bristled cleaning brush” and some “lubricant” (if we are being nitpicky make sure it is a bore cleaning solvent) you start from the breech end and go back and forth in the barrel.

After that, make sure your bore is clean and dry by running a patch through.

Continue running a patch through until the patch comes out clean.

From here, the manual says to wipe down the outside of the barrel with a patch until the patch does not get dirtier.

Sam’s Note: If you have a build-up of carbon and grime on the outside of the barrel, feel free to soak the outside in a bore cleaner and wipe it dry with a rag.

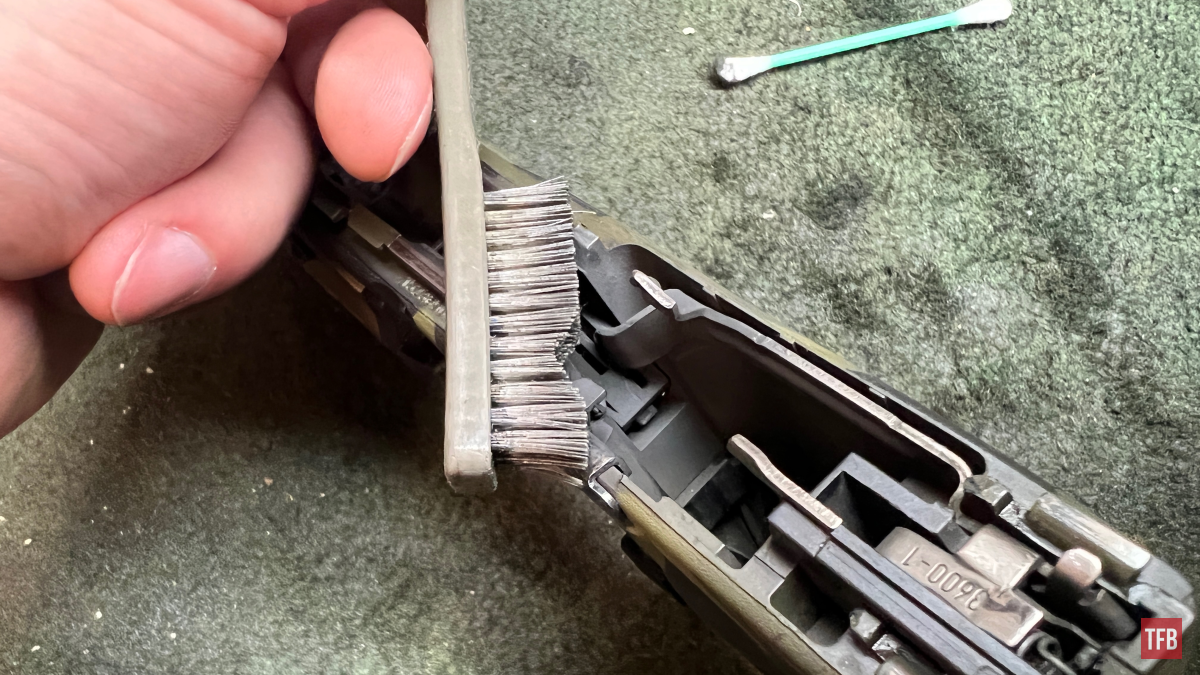

Slide: As far as the slide goes, use a wet nylon bristle brush to clean the rail cuts

Holding the muzzle portion of the slide face down, using the “wet” nylon bristle brush, scrub the breech face with special attention to the extractor claw.

Scrub all other dirty and carbon-caked areas of the slide.

Wipe all exposed and cleaned areas with a patch (rag) until clean.

An important note that the Glock Armorer’s Manual makes is that the copper-colored portion of the slide is a “high-temperature, factory applied lubricant for new pistols”. This is not seen on this Glock since it has a high round count and has been Cerakoted. The cam area (looking at the picture above) is the square jutting out area just above the striker channel.

Frame: This portion of the manual is short and sweet.

Brush the rails on the frame and all other parts that need brushing basically so long as it all gets dried by a rag or patch.

Magazine: The manual warns against the disassembly of the magazine. If need be disassemble it and dry brush and/or wipe down with a cloth.

Lubrication – Glock Maintenance

This is probably the most informative portion of the Glock Maintenance section of the Glock Armorer’s Manual. It goes over the proper spots where lubrication is applied to a Glock pistol. In fact, it colors/outlines those spots with pictures. I do not know how sacred the Armorer’s Manual is. For all I know there are pictures of these pages scattered all over the internet. For the sake of original pictures and me being more hands-on about it, I attempted my own rendition. Please excuse the shaky drawing on these pictures. All the red portions are the spots and or encapsulated areas meant to be lubricated.

Barrel: Make sure to use quality gun oil or grease, and lightly apply it with a brush or patch around the barrel and lugs.

Lightly apply oil or grease with a brush or patch on the barrel hood and lugs on the top of the slide.

Slide: Extend a drop of oil all the way along each rail.

Lightly wipe down the interior portions of the slide.

Note: Never lubricate the firing pin channel! Solvent or lubricant left unchecked in this place may contaminate primers and result in a failure to fire.

Frame: The only portion of the frame that may require lubrication would be the area where the trigger bar kisses the connector at the rear of the frame. Place a small drop there if need be.

Final Thoughts: By The Book – Glock Maintenance

In closing, I feel like the Armorer’s Manual could do better in some spots and maybe be a little more specific but it is probably kept simple and vague for reasons that are pure speculation on my part. This was not supposed to be a review of it but rather to showcase the process held within. I recommend using a quality solvent/bore cleaner to clean your firearm. It is always easier to wipe off and dry up. Lubricants are a fine a dozen so take your pick. Just remember per the manual’s warning, you really don’t need much. As we all know these guns are capable of going on and living a long life without frequent maintenance. However, it would feel wrong to tell you to simply forget about it. Always clean and maintain your firearms no matter their notable durability and endurance. See you next week and take care!

Glock Maintenance

As always, thank you for reading TFB! Be safe out there, have fun while shooting, and we will see you next time for the TFB Armorer’s Bench brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal! Also, let us know what you think in the comments below! We always appreciate your feedback.

Caldwell Pro Range Glasses, Clear

The Caldwell® Pro Range Glasses feature a stylish wrap-around design and are a great choice for all shooters. They feature an adjustable nose piece and temples for all day comfort. The scratch resistant lens meets ANSI Z87.1 standards and offers 99.9% UV protection.

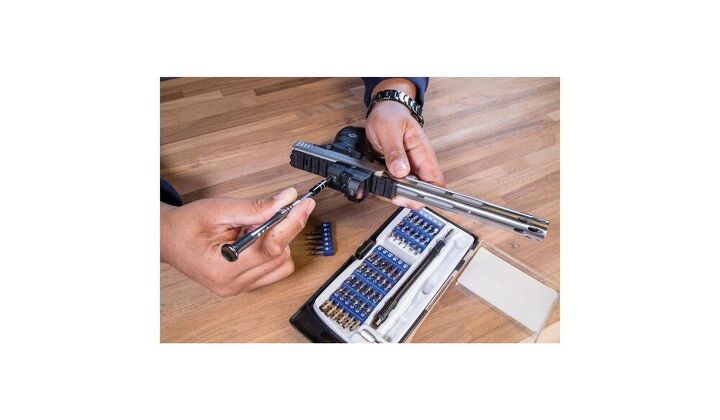

72 Piece Professional Gunsmithing Screwdriver Set

The Wheeler 72 Piece screwdriver set features 54 hollow-ground flat bits, 4 phillips, 3 torx, and 8 specialty bits all made from durable S2 tool steel with a 56-58 Rockwell “C” hardness rating. The precision-engineered bits have a concave shape that allows for insertion all the way into the screw slot of rmaximum contact to prevent burred, buggered, busted up screw slots. The kit also includes 2 non-slip, overmolded plastic handles that come in a convenient hinged storage case whcih includes a bit location guide.

Universal Bench Block

Made of non-marring urethane, the Universal Pistol Bench Block is perfect for use on M1911 pistols as well as other firearms such as 10/22s.

Tipton ULTRA GUN VISE

The Tipton® Ultra Gun Vise features a completely modular interchangeable design to allow virtually any shape firearm or crossbow to be cleaned and worked on with ease. The ball and socket articulating clamp pads allow for the pads to adapt to any surface. The dual clamp technology rigidly holds any firearm shape in place, while the rigid steel tube frame structure allows for complete access to your firearm or crossbow. The front and rear clamps are both height and length adjustable, and feature fast-turn knobs allowing for quick clamping. The solvent-resistant accessory and tool trays are movable and removable to stand up to even the toughest jobs.

Precision Micro Screwdriver Set

Frankford Arsenal Stainless Steel Dial Caliper

Reloading ammunition requires attention to many critical cartridge dimensions, including case length, neck and base diameters, overall length, primer pocket depth, etc. Verifying these dimensions is quick and convenient with the Frankford Arsenal® Stainless Steel Calipers. These calipers are accurate to within .001″. The calipers allow you to measure inside and outside diameters, plus depths. You will find them useful for many measuring tasks on and off the reloading bench. Packaged in a convenient and protective case.

Your Privacy Choices

Your Privacy Choices