Yes you read that right. Defense distributed has taken their Ghost Gunner desktop CNC to the next level. They are now offering jigs and code to mill a zero percent receiver (raw billet blank aka brick of aluminum) into a lower receiver. Life finds a way to be ungovernable.

Ghost Gunner @TFB

- TFB Review: Ghost Gunner 3 – Harder, Better, Faster Gun Making Robot

- TFB Behind The Gun Podcast Episode #18: Defense Distributed Ghost Gunner

- [TFB GUNFEST] Homemade AKs with the Ghost Gunner 3 and Defense Distributed’s 2021 Plans

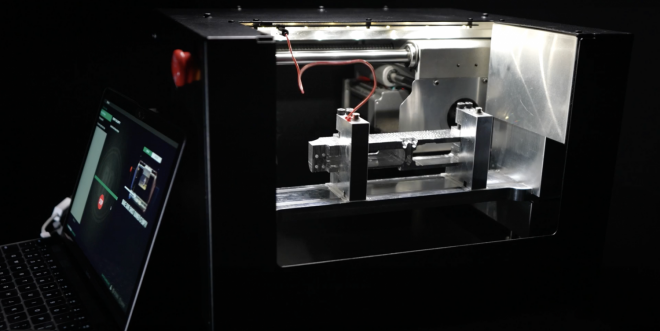

Ghost Gunner released this video teasing their zero percent receiver.

If you recall in my review of the Ghost Gunner 3, the GG3 can machine faster and harder materials than previous versions of the Ghost Gunner. One of the draw backs to the GG3 though are the jigs. The jigs are injection molded plastic. There are files that you can get to 3D print your own jigs as well. The GG3 can only machine so fast and so frequently since it does not have any type of cooling. Typical CNC use air flow or liquid cooling. Not really possible for the GG3. Some GG3 owners have tried to see how fast they can keep making receivers out of 80% receivers. After a number of them the heat gets to be too much and can warp the plastic jigs. Well according to this video it looks like they have come up with metal jigs.

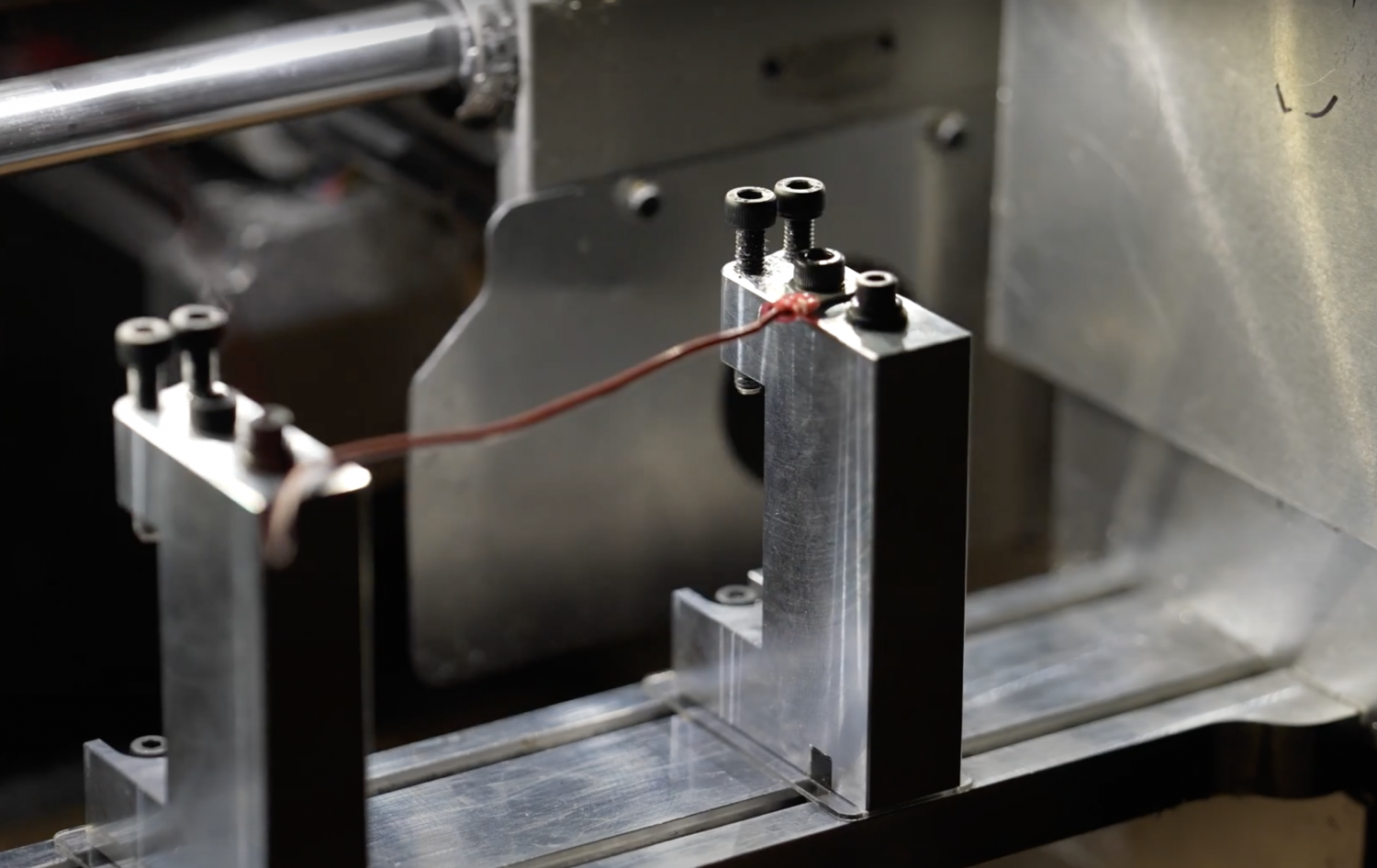

So there are some interesting things happening here. As I mentioned before, the typical jigs for the GG3 are plastic. This isolates the lower receiver from touching the build plate below. There is a probe wire that is bolted to the grip screw. When the GG3 probes the receiver it is learning where the piece is in 3D space. It needs to know where it is so it can precisely machine the FCG pocket, selector hole and trigger pins. If the lower receiver touches the build plate it completes the circuit for the probe and you get a fault. Probing is performed with the 1/4″ end mill touching distinct areas of an 80% receiver. So why do I bring this up? The zero percent receiver jigs are metal and you are putting in a raw billet blank into it. I am unsure how this does not trip the probing sequence. Wait, if you look closely at the image below you can see what appears to be a thin piece of plastic that separates the jig from the build plate. There you go. That’s how it is done.

One of the biggest questions I had about this process was how do they machine the receiver extension for the buffer tube? The screen shots I post below answers this question. The image below appears to show the zero percent receiver in various stages of completion.

What I was not expecting was that Defense Distributed went with a modular zero percent receiver design rather than one solid receiver. The lower is broken up into three parts.

See the receiver extension? also look at the mag well and trigger guard. Those are separate pieces.

Here are the three pieces. I am still not sure how the receiver extension is machined. Is it a component you buy? Or is there actual code to machine and thread that part? What bit do they use?

In this teaser shot it looks like the upper half of the receiver is pivoted into the lower half.

Here you can see the holes for the screws to attach the receiver extension.

I am very excited for the zero percent receiver. While I greatly dislike the need for it, I do admire Cody Wilson and everyone at Defense distributed for coming up with the zero percent receiver so we can maintain our second amendment rights. It should not have to come to this but we the outlook is bleak.

James Reeves interviewed Cody Wilson and he foreshadows a bleak future regarding the status of 80% receivers.

I will try and see if Defense Distributed can send their zero percent receiver kit in for review as I still have the Ghost Gunner 3. So stay tuned.

Your Privacy Choices

Your Privacy Choices