Welcome everyone to the TFB Armorer’s Bench! As mentioned in the little blurb, this series will focus on a lot of home armorer and gunsmith activities. In this article sponsored by Wheeler, Tipton, Caldwell, and Frankford Arsenal, I decided to go over one of Wheeler Engineering’s many quality tools in the last article looking closer at the Wheeler Armorer’s Handgun Sight Tool. I recently had a chance to swap out a coworker’s Glock sights and I felt this was an excellent opportunity to show how this tool is intended to be used. This handy compact tool can make a tough time-consuming job a breeze. Let’s dive into using the Wheeler Armorer’s Handgun Sight Tool!

TFB Armorer’s Bench: Using The Wheeler Armorer’s Pistol Sight Tool

Welcome to our recurring series of Armorer’s Bench which is made possible and brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal who are our sponsors. Here, we at TFB hope to inform, entertain, and even inspire any would-be gunsmith or armorer out there. Ideally, with the information I provide and with the help of our sponsors, you can have some useful knowledge pertaining to the conservation and improvement of firearms technology while at the same time sharing experiences and teaching each other new tips and tricks along the way in the comments. Digging deep into what it is to be an armorer or gunsmith has significance but what is important is what those people do to show they’ve earned that title. I am happy to share my experiences and knowledge and hope it is informative!

Make your personal safety a priority:

- Practice proper gun safety. Always make sure before the firearm hits your bench that it is unloaded and safe to be handled.

- Wear the proper safety equipment. The main one would be safety glasses (decent ones) since parts are often under spring tension and you may work with high RPM tools. Other honorable mentions would be latex gloves or a respirator when working with potentially harmful solvents and oils. Also hearing protection when working with loud machinery or test-firing firearms.

- Modifications, alterations, and customizations will void your firearm’s warranty 9.5 times out of 10. Please take that into consideration before attempting any at-home gunsmithing.

- If you are unsure about proper safety practices, disassembly procedures, or warranty standards, stop, put down the tools, and consult a competent gunsmith.

Needed Materials: Using The Wheeler Armorer’s Pistol Sight Tool

The Wheeler Armorer’s Handgun Sight Tool comes in a cardboard box surrounded by styrofoam and oil-soaked plastic to protect it. Along with the sight tool, it has a manual that actually is fairly thorough and simple to understand. Most of my complaints typically come from laziness or purposeful vagueness in the manual. Aside from the Wheeler Armorer’s Handgun Sight Tool, there are a few other bits and bobs that can come in handy.

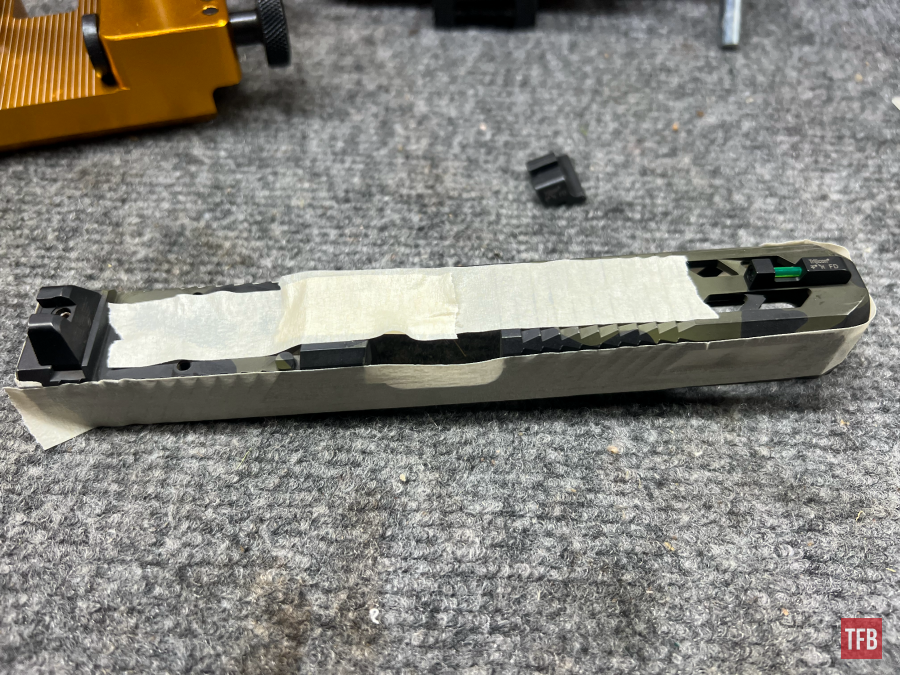

- Tape: The manual itself mentions the use of tape as a form of protecting a slide’s finish. In my experience, this sight tool has never marked up a slide without incorrect use or thoughtlessness on my part. The tape however is a good extra preventative step to take. I recommend using good-quality masking tape since it sticks well and can take a beating.

- Pencil, Pen, or Marker: Some sort of marking tool is good for temporarily and noninvasively marking a previous sight’s position or center. With the previously mentioned tape in place, this is even easier.

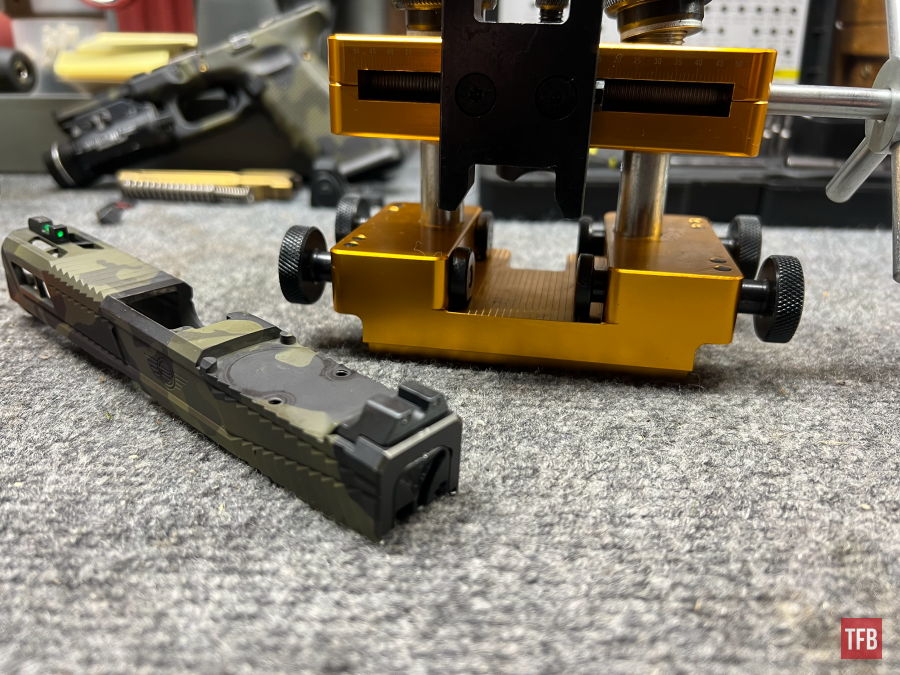

- Handgun Slide, New Sights: Bit obvious… A coworker needed to review some night sights for his Glock so that is the chosen model for this sight tool’s demonstration.

- Other Necessary Sight Tools: These may be tools unrelated to the mass majority of handgun slides and their sights such as a Glock front sight tool which was necessary for this procedure. Luckily Wheeler includes one in their 89 Piece Professional Gunsmithing Screwdriver Set. Otherwise, the only other items that come to mind may be a heat gun or penetrating oil to ease harder sights such as some Springfields and Berettas.

- 3mm Allen Bit or Wrench: This is only necessary if you need to flip the adjustment presser portion of the sight tool. It comes with 90-degrees flipped down and Glock sights are traditionally at an angle. Therefore I had to remove the screws and flip the presser to move forward. I hate this design feature more than anything. A 3mm bit is not included in any of Wheeler’s main screwdriver kits but rather they offer a Metric 30-Piece P-Handle Driver Set. These screws I have heard are a major weak point of the tool and have broken…although I have never had this happen to me I can see how that may happen with high pressures and impatience.

- Propper Applicable PPE: Yeah, boring I know but when working with tools that can exert a high amount of pressure can cause catastrophic breakages and damage with misuse. Be careful and at the very least wear some safety glasses.

Using The Wheeler Armorer’s Pistol Sight Tool

Note: You will often see the upper portion of this sight tool over the cutout on the base or on the other side. I looked through the manual to see if there is any warning or literal mention of a “proper” way or direction to have the top on. Everything was very inconclusive and conflicting so as of right now, I will have to go by experience. I have not noticed increased difficulty or ease of use while having the top portion facing either way.

Step One: Wheeler Armorer’s Pistol Sight Tool

Gather your new set of pistol sights, Wheeler Sight Tool, and a handgun, and remove the slide and its contents.

Step Two: Wheeler Armorer’s Pistol Sight Tool

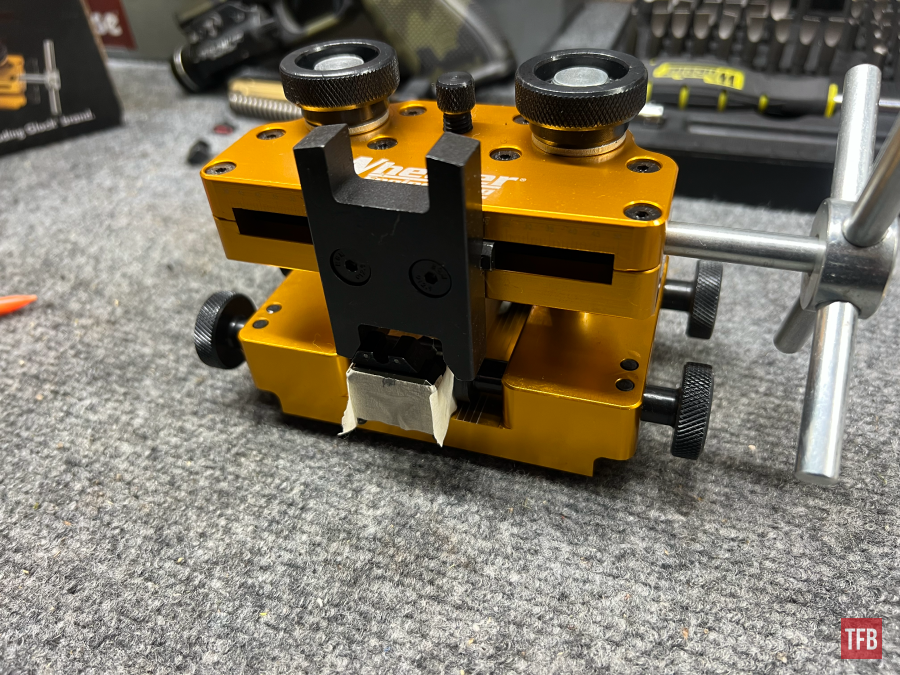

Establish if you need to flip the presser piece of the sight tool in order to apply the correct pressure over the best amount of surface area. Shown below is the factory 90-degree setting and the new Glock sights that are at a different angle. This presser will need to be flipped.

Step Three: Wheeler Armorer’s Pistol Sight Tool

Flipping the presser is an easy thing to do if you have a 3mm or #3 metric Allen wrench or bit. Unfortunately, Wheeler does not offer metric bits in their screwdriver kits but they do have a 30 Piece SAE/Metric Hex and Torx P-Handle Set. This is not ideal since you want to make sure these screws are at their correct inch-pounds.

Step Four: Wheeler Armorer’s Pistol Sight Tool

Remove the screws and flip.

Step Five: Wheeler Armorer’s Pistol Sight Tool

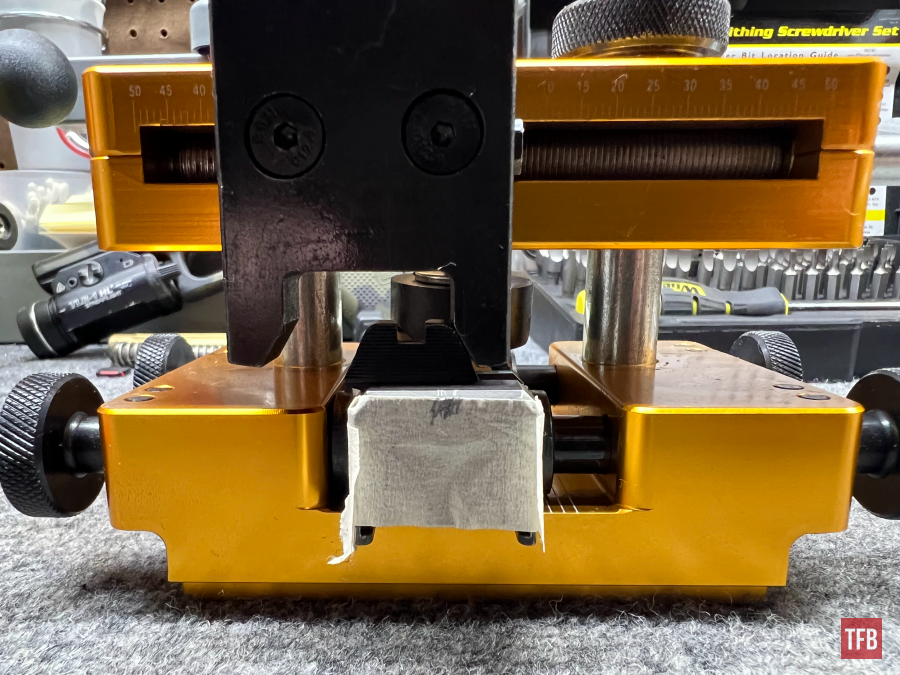

Next, I would recommend putting a protective coating of tape around your slide. No need to go crazy with it, just a few strips on each flat portion of the slide to ensure that any slippage will harm the tape before the finish of the slide.

Step Six: Wheeler Armorer’s Pistol Sight Tool

With tape on the backplate portion of the slide, you can use a pencil or some sort of marking tool to make a vague reference of where the old sight was centered in order to help with the new one.

Step Seven: Wheeler Armorer’s Pistol Sight Tool

With the slide all taped up and protected, let us get back to prepping the sight tool. The manual mentions retracting the side compressors all the way as shown below.

Note: There are discrepancies in the original manual versus the one I have with my press. The manual I am referencing is “Revision B” which asks you to do the above step as well as the next one. But! Here is a funny thing…there is another manual called “Rev B” and has the same manual number. It is confusing but take it from me that the one I received is the most up-to-date as of this date.

Step Eight: Wheeler Armorer’s Pistol Sight Tool

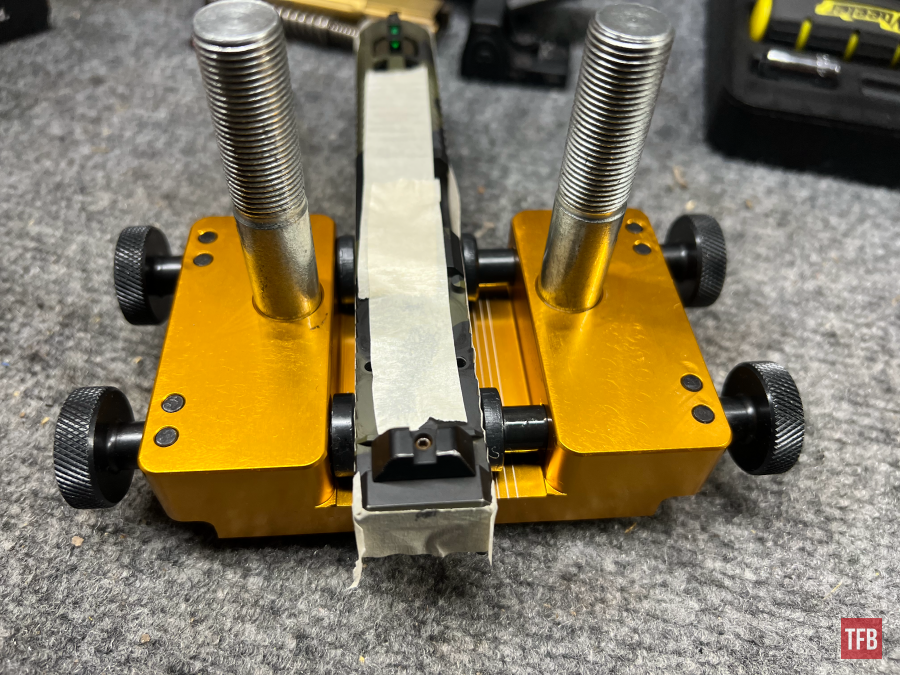

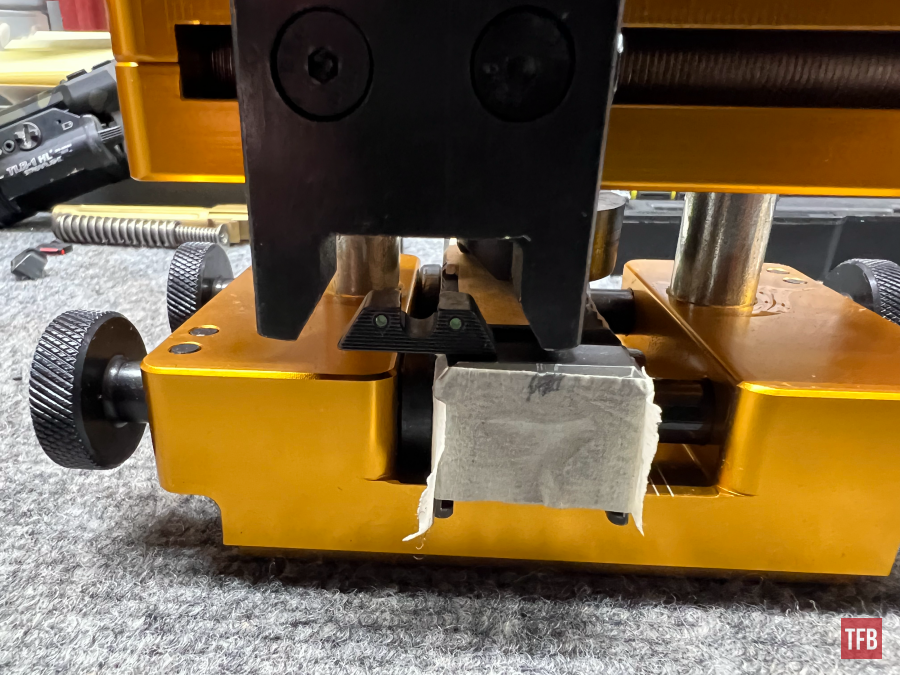

From here the manual mentions keeping one side of the bottom clamps bottomed out and fully retracted. Ideally, the side you are pushing towards should be bottomed out. In this case, it will be the left side since we are driving out the Glock sight to the left.

Step Nine: Wheeler Armorer’s Pistol Sight Tool

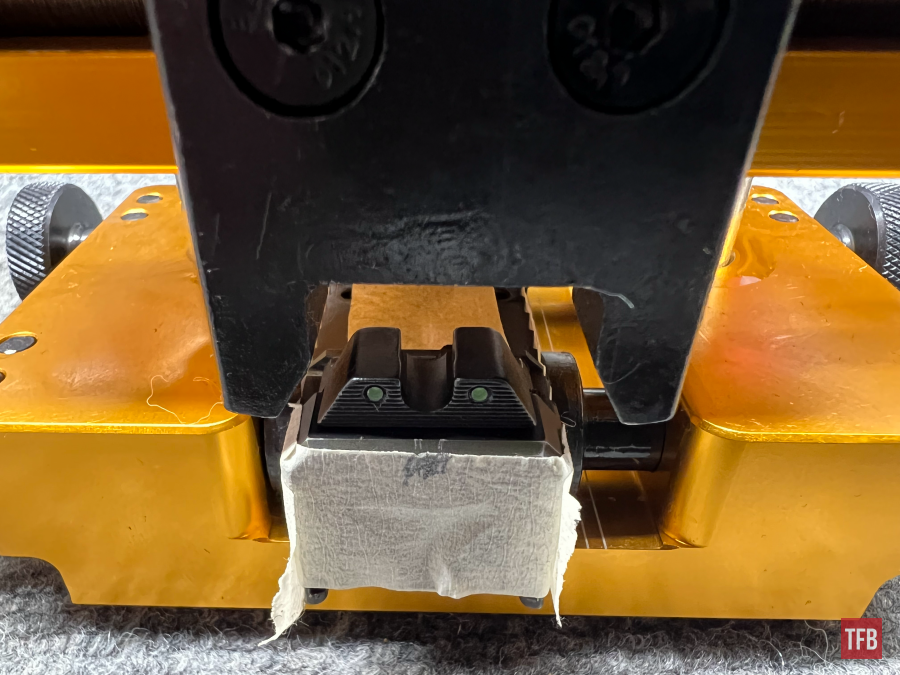

Place the slide against the left side and tighten the right clamps. The clamps are anodized aluminum but the tape should still be there as a safeguard.

Make sure to loosen any rear sight set screws.

Step Ten: Wheeler Armorer’s Pistol Sight Tool

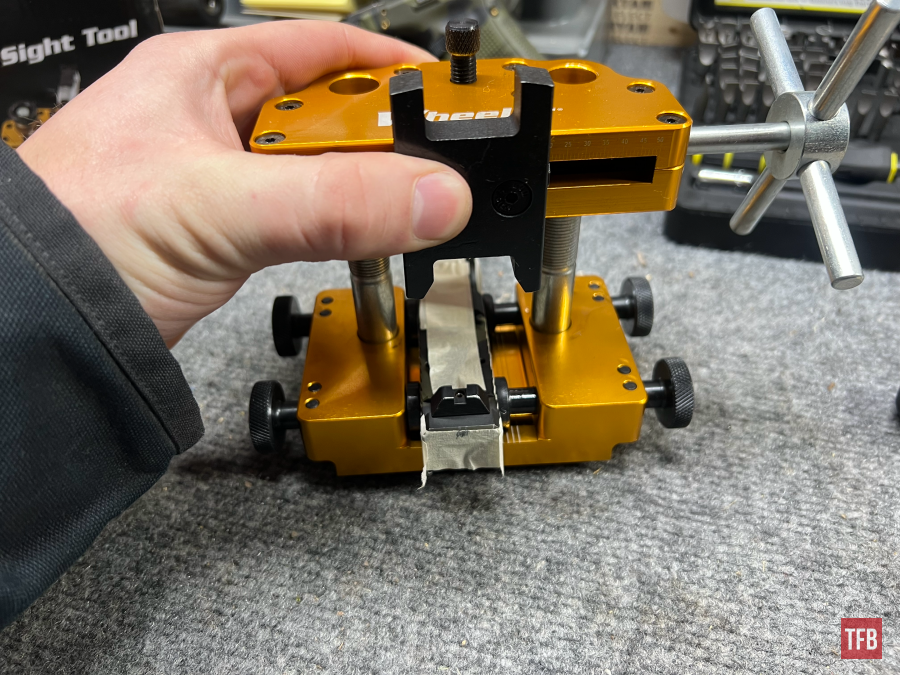

Place the upper portion of the press over the slide.

Step Eleven: Wheeler Armorer’s Pistol Sight Tool

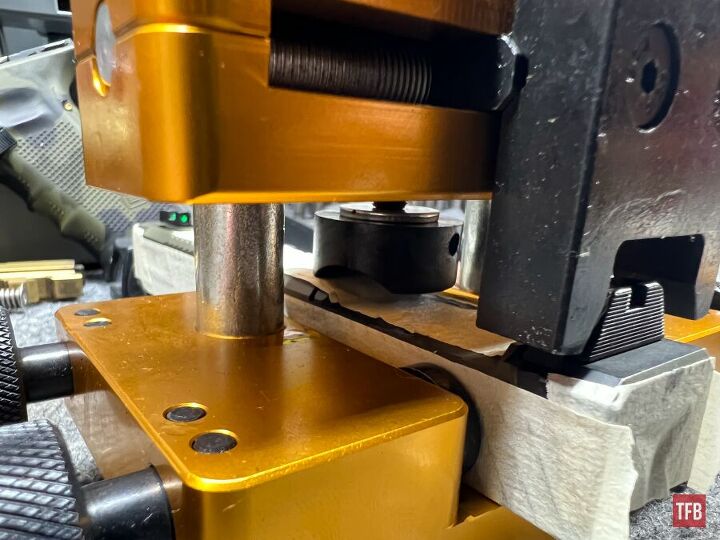

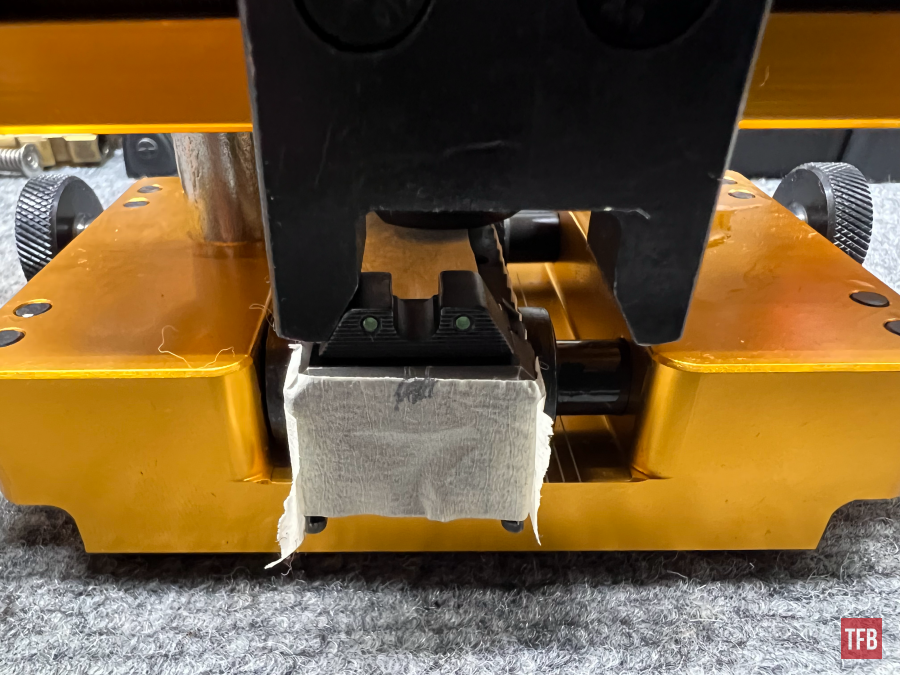

Pay close attention to the riser and how it is sitting. The flat portions are for any flat-topped pistol like the Glock for example (although only one-half of it is contacting since I was missing a MOS plate). The half-moon cut is for rounded top slides like 1911.

The riser is responsible for setting the depth of your presser. Too low and you will contact the slide and potentially damage it and too high you will not have ideal surface pressure and the pressing portion will be harder than it should.

Step Twelve: Wheeler Armorer’s Pistol Sight Tool

After setting your depth with the riser portion of the press, you can tighten down the top with the knurled fasteners.

Step Thirteen: Wheeler Armorer’s Pistol Sight Tool

Next, it is pretty simple. You just use the crank/wheel to slide the pusher to the left and press the Glock rear sight off of the slide.

Step Fourteen: Wheeler Armorer’s Pistol Sight Tool

With the old rear sight pressed off of the slide, we can please the presser in an ideal position and put the new sight in as far as it will slide into the slide.

Step Fifteen: Wheeler Armorer’s Pistol Sight Tool

With the new sight at the ready, simply apply small increments of pressure until it begins to slide into place.

Step Sixteen: Wheeler Armorer’s Pistol Sight Tool

When approaching the center or perceived center, one thing I use besides my marked portion of the tape is paying attention to the space on either side of the sight itself. Even them out and you should be in the center of the slide.

Closing Thoughts: Using The Wheeler Armorer’s Pistol Sight Tool

Well, there you have it! At the end of the day, driving a sight in and out of a pistol slide can be done with a punch and hammer but why make it harder on yourself and potentially harm the slide you are working on? The Wheeler Armorer’s Handgun Sight Tool is far from the end all beat all sight tool. I have worked with cheaper sight presses and some very expensive ones and they are never perfect. To me, the biggest help you can give yourself is to read their manuals and hopefully they put their own tips and tricks in there when working with their tools. Wheeler does a great job in theirs and I enjoy using it with only minor occasional difficulty. There are a whole host of methods and tips that I encourage you all to kindly share with one another in the comments and enrich the world of benches out there with helpful information. Stay safe out there and I will see you next time!

Note: As of writing this, I saw that Wheeler currently is offering a majority of the tools and items on their site up to 40 % off discounts. Wheeler has this tool on sale for $229.99! Also, a free Laser Bore Sighter with $150+ purchase.

As always, thank you for reading TFB! Be safe out there, have fun while shooting, and we will see you next time for the TFB Armorer’s Bench brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal! Also, let us know what you think in the comments below! We always appreciate your feedback.

Pro Range Glasses, Clear

The Caldwell® Pro Range Glasses feature a stylish wrap-around design and are a great choice for all shooters. They feature an adjustable nose piece and temples for all day comfort. The scratch resistant lens meets ANSI Z87.1 standards and offers 99.9% UV protection.

Armorer’s Handgun Sight Tool

The Wheeler® Armorer’s Handgun Sight Tool is designed for adjusting, installing or removing dovetail style front and rear handgun sights. Made of high end materials, the Wheeler® Armorer’s Handgun Sight Tool will last for years of hard use.

Universal Bench Block

Made of non-marring urethane, the Universal Pistol Bench Block is perfect for use on M1911 pistols as well as other firearms such as 10/22s.

Wheeler Delta Series Compact Multi-Tool

There is no longer a need for a tool box at the range when you have the Wheeler Delta Series Compact Multi-Tool. With a satin finish and stainless steel construction, this tool is not only handy, but durable. The multi-tool design can be used to perform many different functions in the field. When you need to make adjustments, or scrape some carbon build-up, simply reach down and grab this tool out of the included nylon belt sheath and go to work. After you are finished, snap the tool back in and continue shooting.

Stainless Steel Dial Caliper

Reloading ammunition requires attention to many critical cartridge dimensions, including case length, neck and base diameters, overall length, primer pocket depth, etc. Verifying these dimensions is quick and convenient with the Frankford Arsenal® Stainless Steel Calipers. These calipers are accurate to within .001″. The calipers allow you to measure inside and outside diameters, plus depths. You will find them useful for many measuring tasks on and off the reloading bench. Packaged in a convenient and protective case.

Wheeler 30 Piece SAE/Metric Hex and Torx P-Handle Set

Complete your workbench with the Wheeler 30-Piece P-Handle Driver Set. The sleek molded stand design paired with its ability to be mounted on the wall allow for quick, convenient access to the SAE Hex, Metric Hex and Torx drivers, making it the perfect addition to any work shop.

Your Privacy Choices

Your Privacy Choices