Welcome everyone to the TFB Armorer’s Bench! As mentioned in the little blurb, this series will focus on a lot of home armorer and gunsmith activities. In this article sponsored by Wheeler, Tipton, Caldwell, and Frankford Arsenal, I decided to go over boresighting since it seems like there are quite a few misconceptions on how exactly it works and certain expectations on reliability. So I wanted to run down both the types and techniques to hopefully convey a broader picture to anyone out there who may have questions regarding boresighting. Let’s jump into Techniques and Types – Boresighting!

TFB Armorer’s Bench: Techniques and Types – Boresighting

Welcome to our recurring series of Armorer’s Bench which is made possible and brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal who are our sponsors. Here, we at TFB hope to inform, entertain, and even inspire any would-be gunsmith or armorer out there. Ideally, with the information I provide and with the help of our sponsors, you can have some useful knowledge pertaining to the conservation and improvement of firearms technology while at the same time sharing experiences and teaching each other new tips and tricks along the way in the comments. Digging deep into what it is to be an armorer or gunsmith has significance but what is important is what those people do to show they’ve earned that title. I am happy to share my experiences and knowledge and hope it is informative!

Make your personal safety a priority:

- Practice proper gun safety. Always make sure before the firearm hits your bench that it is unloaded and safe to be handled.

- Wear the proper safety equipment. The main one would be safety glasses (decent ones) since parts are often under spring tension and you may work with high RPM tools. Other honorable mentions would be latex gloves or a respirator when working with potentially harmful solvents and oils. Also hearing protection when working with loud machinery or test-firing firearms.

- Modifications, alterations, and customizations will void your firearm’s warranty 9.5 times out of 10. Please take that into consideration before attempting any at-home gunsmithing.

- If you are unsure about proper safety practices, disassembly procedures, or warranty standards, stop, put down the tools, and consult a competent gunsmith.

Being Realistic: Boresighting

Boresighting is not a perfect science. Sometimes you can pair a boresighter and gun together and it’ll produce great results. Most of the time a boresight will get you ON PAPER at 25 yards. A number of things make it tough for these tools to do their job right. All can depend on the type of boresight, type of firearm, and condition or modifications the firearm has. The most common issues are listed below but the list is a fairly never-ending thing.

- Improperly mounted optics: Scope reticle is not level, scope is contacting anything other than the scope rings, scope is too far off of the gun, etc.

- Inadequate mounting: Screws not tightened to the correct inch-pounds, some mounts are literally plastic and floppy, mounts are the incorrect ones for the said firearm, etc.

- Play between barrel and receiver: Guns where the barrel is easily removable/replaceable such as takedowns or shotguns.

- Distance bore-sighted: If you boresight at 25 yards and shoot at 100 yards you probably will not hit where you think you should.

- Uneven muzzle/crown: Magnetic boresight tools can be put literally off-kilter by an uneven muzzle. Most rifles are precisely flat (for lack of a better word) whereas a bird barrel on a shotgun does not have that honor. The Savage 220 slug gun is a good example of a shotgun that does have a precision ground muzzle.

- Dirty bore/chamber: This can throw off stem style or cartridge style in-bore boresighters.

- Damaged bore: This can throw off stem style or cartridge style in-bore boresighters.

- Damaged chamber: This can throw off cartridge-style in-bore boresighters.

- Damaged crown: This can throw off magnetic boresighters.

Types: Boresighting

To me, boresighters can be separated into a few basic categories. They each have pros and cons. They also may blur the lines that divide them and blend two aspects. You have laser boresighters, pictographic/grid boresighters, and in-bore boresighters.

Laser Boresighters

Laser boresighters are super common these days, are pretty accessible, and are seemingly the most accepted by the public at large. Laser boresighting works by projecting a laser pointer at a specified distance (usually around 25 yards) roughly from the same position of the bore. This can be achieved by cartridge-style laser boresighters, magnetic laser boresighters (like the Professional Laser Bore Sighter that Wheeler offers), or from a mechanically tightening stem of a laser placed in the muzzle.

One deceiving aspect of laser boresighting is it sounds pretty straightforward on paper. You just put your crosshairs where the laser is right? Well, yes you do but that does not mean that is where it should be and that is not entirely anyone’s fault.

Photo Credit: Wheeler Engineering

Cartridge laser boresighters are susceptible to tolerances of the boresighter itself or dirty/worn/damaged chambers. Magnetic laser boresighters that are mounted at the muzzle are at the mercy of the muzzle itself. If it’s not as flat and true as possible or the crown is damaged and misshaped that will throw things off. Stem style laser boresighters are a great alternative to both the cartridge and magnetic style but overall will still be affected by the same problems of the magnetic style; albeit in less severity in my experience.

In-Bore Boresighters

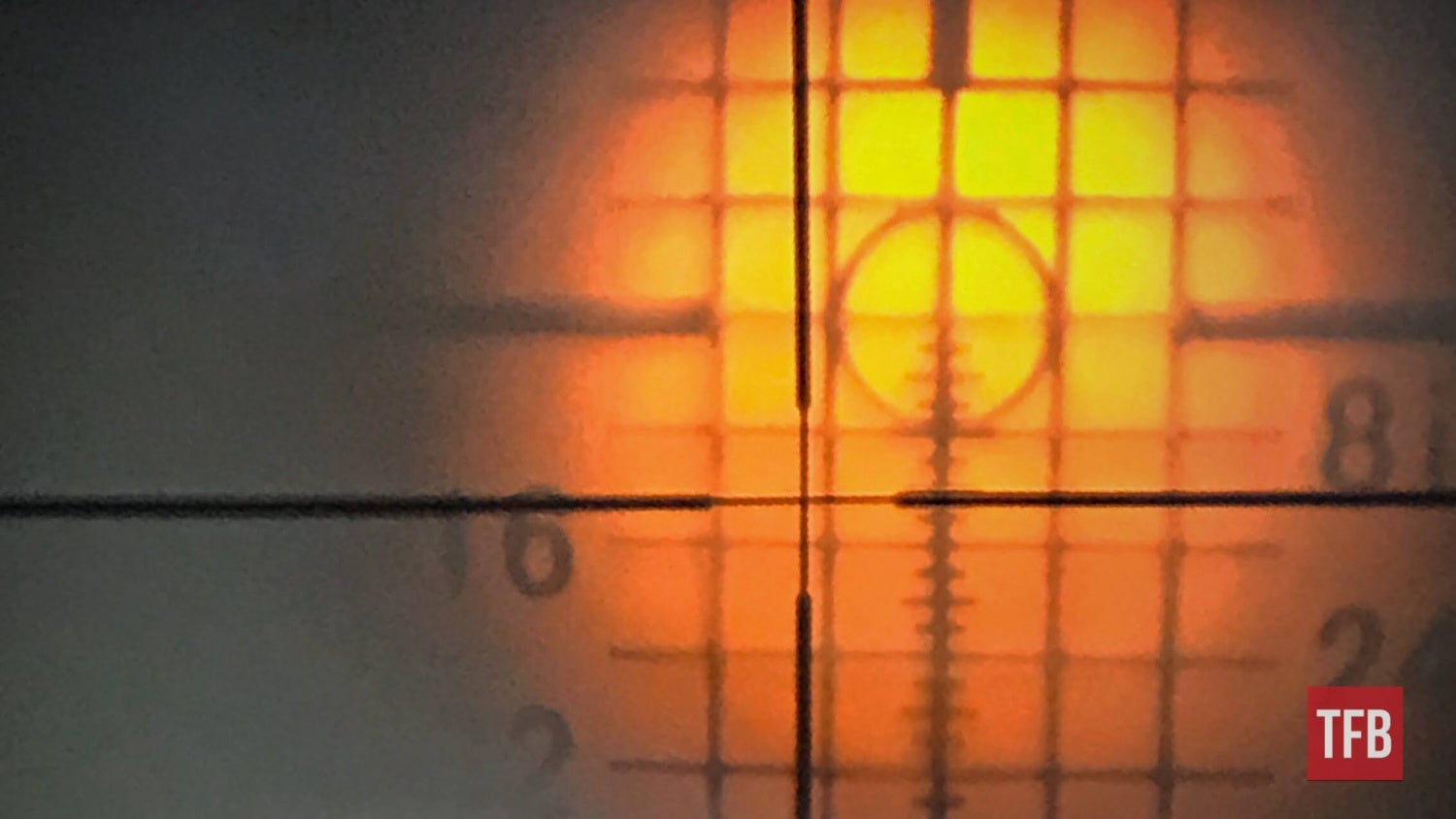

In-bore boresighters are boresighters that in one way or another literally enter the bore of a firearm. A majority of them will be laser boresighters but there are exceptions. The previously mentioned cartridge boresight or the stem style are in-bore boresights. There are boresights that use a stem to be in the bore while a cone-shaped window is held over the top of the bore. When looking through the scope you see a grid system that is supposed to mimic that of a target at 100 yards.

I personally have found in-bore boresighters especially useful for shotguns. I live in a state and area where there are slug zones and people hunt with their shotguns as a result. Contrary to their appearance, most generic shotgun muzzles are not cut precisely because well they are shotguns…usually a “good enough” is the equivalent measurement. Rifled shotgun barrels usually are very much precise and offer a wonderful space for a magnetic boresight upfront at the muzzle but what about the regular old bird barrels? Cartridge-style boresights in bird barrels do the trick just fine because a rifled slug has quite a bit of group variation.

Pictographic/Grid Boresighters

The gird boresighter category is my favorite because when you can properly attach it to the firearm you need boresighted it can work wonders. I have had a lot of experience with Luepolds Zero Point Boresight which is a magnetic attaching grid-based boresight. These are now unfortunately discontinued and I do not know why. They work amazingly. I have had customers start as far out as 100 yards with a fresh boresight and hit paper which to me is astounding.

When I was in school for gunsmithing we had grid boresights that used the in bore stem style attachment and those seemed to work really well too. I think the big difference is grid-based boresights show a pictograph that is meant to represent 100 yards whereas laser-style boresights are up to the user to choose a distance.

Techniques/Tips: Boresighting

- No Tool Boresighting: You do not need a tool to boresight a gun. Firearms that are able to have the bolt removed and be able to see through the breech can do this easily. this includes all bolt action rifles and even AR15s. Simply put the barreled action on a rest of some sort and peer through the barrel from the breach. Ideally, you will be able to spy a target or object to focus on while boresighting. Compare and adjust your crosshairs according to the image seen in the barrel.

- Start at 25: Pretty straightforward and simple and arguably not boresighting but if you start at 25 yards you shout hit close to your target at the very least which should give you a good idea. A scope out of the box from a reputable company should be dialed in perfectly in the middle. That does not mean that it is dialed in relation to your bore by any means.

- Use a Rest: Us a lead sled, rest, vise, etc. This offers a fixed and stable position to dial your crosshairs in as precisely as possible without the human error of movement.

- Enhance Your Target: When using a laser boresight of some sort, it is helpful to place a small reflective sticker on your target. This gives you something to aim for as well as something that will make your laser appear bigger at longer ranges so it is easier to see.

Closing Thoughts: Techniques and Types – Boresighting

I cannot stress it enough that boresighting is not a perfect science. There are so many variables that go into it that usually make the experience pretty so/so. It is good to have a game plan but I by no means recommend getting every type of boresighter out there. There is not a perfect one just a perfect one for a specific gun. As with any sort of tips and tricks style article, I encourage all the folks out there to talk with one another in the comments and offer up any information I may have missed. Be safe out there and see you next time!

As always, thank you for reading TFB! Be safe out there, have fun while shooting, and we will see you next time for the TFB Armorer’s Bench brought to you by Wheeler, Tipton, Caldwell, and Frankford Arsenal! Also, let us know what you think in the comments below! We always appreciate your feedback.

Pro Range Glasses, Clear

The Caldwell® Pro Range Glasses feature a stylish wrap-around design and are a great choice for all shooters. They feature an adjustable nose piece and temples for all day comfort. The scratch resistant lens meets ANSI Z87.1 standards and offers 99.9% UV protection.

Professional Laser Bore Sighter, Green

The Wheeler Engineering® Professional Laser Bore Sighter uses a high power daylight visible green laser and a high-strength magnetic connection to the barrel to deliver fast accurate bore sighting. This system works with virtually all firearms; rifles, shotguns, handguns. The magnetic connection to the end of the muzzle provides more precise alignment with the bore without the risk of damaging the bore, compared to arbor style bore devices. A machined aluminum body with soft rubber over-molding houses the laser module. Each unit is hand tuned during the manufacturing process with an innovative calibration mechanism. This allows for maximum precision, thus ensuring the best bore/optic alignment possible. Once precision calibration is completed the laser module is permanently secured in place insuring reliable performance and durability. Molded plastic storage case included. Runs on a single Lithium 123A battery (included).

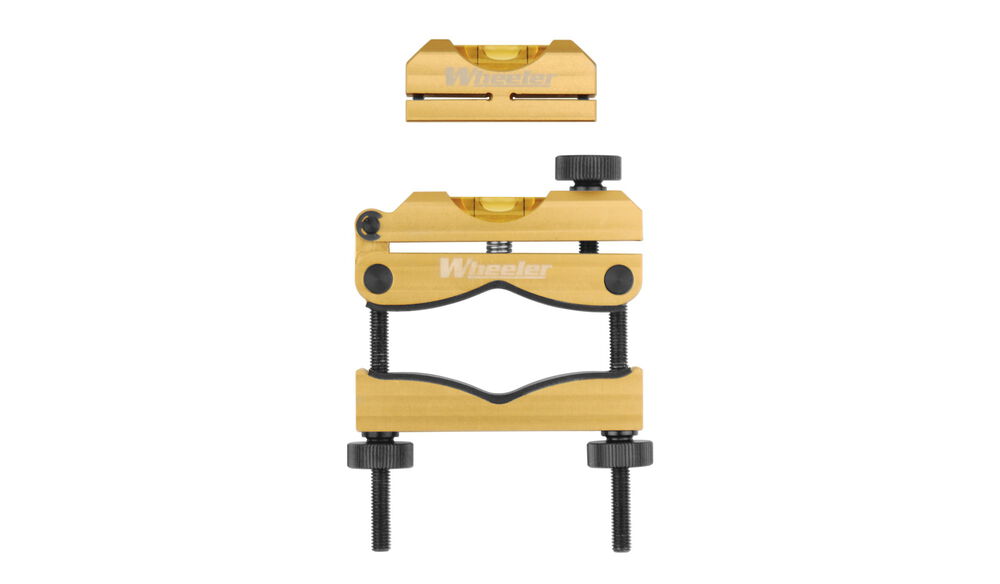

Professional Reticle Leveling System

The Wheeler Engineering® Professional Reticle Leveling System (PRLS) is a precision tool designed to allow a scope to be perfectly leveled on any firearm with ease. CNC machining, factory adjustment calibration set screws, anodized aluminum construction and a protective molded case put the PRLS in a class of its own. The system is comprised of two machined aluminum level housings calibrated to their integrated levels. The Barrel Clamp Level is attached to the gun’s barrel while the smaller Reference Level is placed on scope base, bottom half of a ring or other flat surface perpendicular to the vertical axis of the gun. The gun is then rotated until the Reference Level is aligned. The tuning adjustment knob on the Barrel Clamp Level is then turned until its level is centered to match the Reference Level. At this point, the Barrel Clamp Level is calibrated to the guns axis. The scope can be installed loosely and the Reference Level placed on top of the scopes turret cap. The scope is rotated until the Reference Level is aligned with the Barrel Clamp Level and then simply secured in place. The Wheeler PRLS is the most effective instrument available for precision scope alignment.

Professional Laser Bore Sighter, Red

The Wheeler Engineering® Professional Laser Bore Sighter uses a high power red laser and a high-strength magnetic connection to the barrel to deliver fast accurate bore sighting. This system works with virtually all firearms; rifles, shotguns, handguns. The magnetic connection to the end of the muzzle provides more precise alignment with the bore without the risk of damaging the bore, compared to arbor style bore devices. A machined aluminum body with soft rubber over-molding houses the laser module. Each unit is hand tuned during the manufacturing process with an innovative calibration mechanism. This allows for maximum precision, thus ensuring the best bore/optic alignment possible. Once precision calibration is completed the laser module is permanently secured in place insuring reliable performance and durability. Molded plastic storage case included. Runs on a single Lithium 123A battery (included). Makes initial scope adjustment simple, fast and precise.

Stainless Steel Dial Caliper

Reloading ammunition requires attention to many critical cartridge dimensions, including case length, neck and base diameters, overall length, primer pocket depth, etc. Verifying these dimensions is quick and convenient with the Frankford Arsenal® Stainless Steel Calipers. These calipers are accurate to within .001″. The calipers allow you to measure inside and outside diameters, plus depths. You will find them useful for many measuring tasks on and off the reloading bench. Packaged in a convenient and protective case.

Wheeler AR Armorer’s Ultra Kit

Ultra Kit includes: AR-15 AR Armorer’s Vise, AR-15 Combo Tool, Torque Wrench, AR-15 Armorer’s Bench Block, AR-15 Roll Pin Installation Tool Kit, Upper Vise Block Clamp with Gas Tube Alignment Tool, Maintenance Mat with Exploded AR-15 Diagram, Pivot Pin & Roll Pin Installation Tool, AR Front Sight Tool, Delta Ring Tool, Strap Wrench, AR-15 Bore Guide, AR-15 Adjustable Receiver Link, .22 Cal Bore Brush, Bolt Carrier Brush, Chamber Brush, Magazine/Upper Receiver Brush, Nylon Brush Handle, Double-ended General Cleaning Brush, Cleaning Pick Set, and Custom Fitted Carrying Case.

Your Privacy Choices

Your Privacy Choices