Using patented technology, the Sharps Xtreme Performance Bolt (XPB) aims to improve your AR-15’s overall reliability under hard use. This isn’t just another mil-spec bolt carrier group (BCG). Patented asymmetric bolt lugs are designed to cut through heavy fouling, and the XPB’s parts are all made from S7 tool steel. In order to see how tough the XPB really was, I dreamed up a steel-cased torture test, and Sharps Rifle Company kindly sent a couple versions of the XPB over for review.

The Bolts

Sharps Xtreme Performance Bolt Carrier Group in DLC and NiB-X

Sharps was kind enough to ship over both versions of their XPB bolt carrier group. Here’s the product description from Sharps for both.

The Sharps Xtreme Performance Bolt (XPB) Carrier Group Complete is comprised of our patented Relia-Bolt™ and our Balanced Bolt Carrier. Both are machined out of S7 tool steel. The XPB undergoes a 24-hour thermal cycle proprietary heat treatment and is finished with DLC (Diamond-Like Carbon) coating.

The XPB fits standard AR-15/M16/M4 rifles chambered in .223/5.56, Sharps 25-45, and 300 Blackout calibers. The XPB carrier displays the SRC logo machine cut and is visible when the ejection port door is open.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group

The two bolts Sharps supplied were in DLC (Black) and NiB-X Silver coating and boast the following manufacturer specs.

- Batch MPI and HPT tested

- Tensile strengths of 1550-1600 mpa, or 220,000-235,000 psi.

- Toughness of over 200 ft./lb. Charpy C-Notch

- HRC of 46 yields a 15% increase in hardness at the same toughness comparing to Carpenter 158 & 9310

- Mil-Spec Extractor and Ejector Springs, Gas Rings

While the two bolts have identical construction, the two coatings vary slightly. Here’s the information on both the DLC and NiB-X coatings.

Technical Data on DLC Coating

- Coating thickness: 2-4 Microns

- Hardness HV 0.05: HRC 80+

- Deposition method: PVD UBM/PACVD

- Friction vs Steel: dry 0.1

- Color: Black

NiB-X Coating

- Hardness HV 0.05: HRC 70+

- Friction vs Dry Steel: dry 0.1

- Color: Hyper Silver (Polished)

Specifically engineered NiB-X nickel boron coating to provide long life, high reliability and easy cleaning and maintenance. The BCG components are coated and polished to reduce fouling adherence. Especially beneficial in short barrel setups and suppressed platforms.

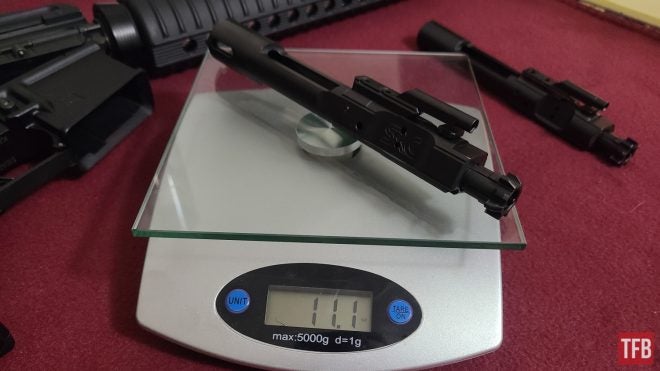

Mil-Spec AR-15 BCG Weight

In order to have a benchmark, I removed a mil-spec bolt carrier group from this M16A4 that weighs in at 11.6oz. Not bad, but certainly nothing new and special either.

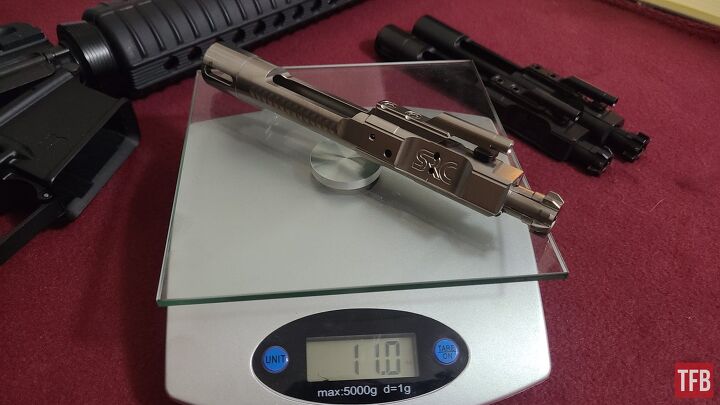

Sharps Xtreme Performance Bolt Carrier Group Weight

Both the sharps XPB in DLC and NiB-X weighed in at 11oz. So you do get a slight weight saving with the XPB.

Sharps Xtreme Performance Bolt Carrier Group Weight

And yes, I’m going to go ahead and round down to 11oz with the DLC coated bolt. I’d forgotten to weigh it before testing, and I’m sure there’s 0.1oz of carbon on there somewhere that I wasn’t able to clean off. But we’ll get to that later.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group

The real test would be a 1,000 round endurance test. Using a post-sample M16A4, I’d attempt to burn through an entire case of Wolf steel-cased ammo. This would test the durability of XPB’s design, finish, and overall construction.

Torture Test

TFB Review: Sharps Xtreme Performance Bolt Carrier Group

In order to better see any wear on the XPB after the test, I opted to use the DLC-coated XPB. This would only be lubricated at the begging of the test using some Lucas Extreme Duty gun oil. After that, it wouldn’t be touched until it’d eaten all 1,000 rounds of steel, in one sitting.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — 1,000 Round Wolf Torture Test

It’s important to note that AR-15 pattern rifles do not like steel-cased ammo. Yes, you can use it, but you need to be prepared for any failures caused by ammo.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — WWI Cooling Methods

Steel ammunition is both more abrasive and less malleable than its brass counterpart. So in an already tight chamber space, it will foul your chamber faster. In addition, those more abrasive steel cases will expand more rapidly as the chamber temperature increases. This will leave you with a spent case that will refuse to extract until you let the chamber cool. In order to get around this, I had to stop every couple of mags and lightly mist the chamber with some water.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Back In Action

It’s a slightly annoying process, but WW1 cooling methods aside, the XPB was chewing through this VERY dirty steel-cased ammo effortlessly and ejecting perfectly.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — 1,000rd Wolf Torture Test Survival

When it was all said and done, the XPB had chewed through an entire case of Wolf without a single bolt-induced malfunction. I did end up sticking two cases due to an overzealous firing cycle, but we’ll chalk that up to “having too much fun”.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — The Aftermath

The bolt was absolutely filthy at this point. It was apparent that all the oil I’d started with was now totally gone. It was time to head home to see how worn the XPB was, and to see how easy it would be to clean.

After Action Report and Cleaning

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Cleaning and Inspection

With the bolt removed from the M16, it was hard to get a decent photograph. It was so dirty that the camera didn’t know where in the carbon blur it needed to focus.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Bolt/Carbon Removal

In the process of removing the bolt from the carrier, I simultaneously pulled an almost perfect sleeve of carbon from the inside of the carrier.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Bolt/Carbon Removal

The coating on the XPB was slick out of the box, but this was a sizeable amount of carbon that just fell out. A very good sign that I wouldn’t be spending an entire afternoon cleaning the XPB.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Dry Wipe Down

When I pulled the XPB at the range I’d inadvertently wiped some of the carbon off the left-hand side of the bolt. Now with the bolt cool, I wanted to see how easy it would be to wipe the rest off without solvents.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Dry Wipe Down

After just a few passes with a paper towel, the left-hand side was very clean and had almost no visible signs of wear. I’d just need to hit this with a nylon brush to clean out the remaining carbon foul.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Hoppe’s Clean Up

Cleaning the XPB with a handful of Q-tips, a nylon brush, and a bottle of Hoppe’s No.9 took all three Q-tips and roughly 10 minutes. The DLC coating was very slick, and only a light layer of Hoppe’s No.9 was enough to remove 99% of the carbon foul. Good enough for me.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Extractor Wear

Extractors are the most heavily worn part when running steel-cased ammo through an AR-pattern rifle. While the extractor did show some wear, it wasn’t enough to be measurable using calipers. I’ve seen more than a few factory extractors sheer off when subjected to the same treatment, so I was very impressed by how well this one held up.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group — Locking Lug Wear

Sharps indicated the angled cuts on the bolt are there to reduce the contact bearing surface on the front of the chamber during lockup. This is designed to reduce failures to lock into battery when the platform is badly fouled. Well, I can tell you the platform was BADLY fouled, and this system ran flawlessly. Not to mention that tiny silver corner was the only wear I could spot on the bolt lugs.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group

All cleaned up and ready to be re-installed, the Sharps XPB looks pretty much as good as new. Everything from the coating to the components work perfectly.

Pros and Con’s

Sharps promised durability and reliability with the XPB, and I have to say the bolt delivers in both areas. Even with heavy fouling, the bolt never failed, and the ejection pattern remained very consistent under prolonged full-auto fire.

TFB Review: Sharps Xtreme Performance Bolt Carrier Group(s)

The overall design is a bit flashy, and part of me wished there was a more plain-looking version of the XPB. I can understand the science behind fewer contact points or asymmetric lugs, but sometimes less logos on a bolt is better.

The Verdict

TFB Review: Sharps Xtreme Performance Bolt Carrier Group

The Sharps XPB in DLC will set you back $199.99, and the XPB in NiB-X Silver costs $229.99. A little more expensive than other mass-produced BCGs on the market, but considering the overall construction and quality of these two, I think the price is fair. If I had to recommend a BCG for hard use, or for use on dirtier platforms (like .300 Blackout), I think the XPB is seriously worth considering.

Thank you to Sharps Rifle Company for sending these over for review, and thanks for reading! For more information on the XPB or other Sharps products, head on over to the Sharps Rifle Company’s website here.

Sharps XPB Carrier Groups can be purchased from Sharps directly via the links listed below.

Sharps Xtreme Performance Bolt (XPB) Carrier Group in DLC

Sharps Xtreme Performance Bolt (XPB) Carrier Group in NiB-X Silver

Your Privacy Choices

Your Privacy Choices