Last fall, I wrote about my experience with the ATF Form 1 process to make a Short Barreled Shotgun (SBS). Between buying my 1980’s vintage Remington 870 Magnum, getting the ATF approval, and actually making it into an SBS has been a long time, admittedly though, purely self induced. My goal has been to do as much of the work myself, rather than to send it off and have the work done for me. That way, I save some money, and learn things in the process.

MAKING A SHORT BARRELED SHOTGUN

From the start, I wanted to make an SBS out of a Remington 870, primarily because the standard, four-shot magazine tube reaches roughly 12 inches, which would be nice and flush with my desired barrel length. I began my search and found a Remington 870 Magnum that looked like it needed some TLC for $200 at a local pawn shop. I was glad it was an older model, not only for the lower price but for the nice smooth metal, rather than the more tactical parkerized models that never feel pleasant to my hands. The bluing on the receiver of the new-to-me 870 was quite neglected underneath an old Weaver side-mounted optics plate, and would also need some attention. I knew I might make mistakes, but I was willing to put in the time and effort to make it look, and be as good as I hoped it could, so this would also become a shotgun restoration project as well.

I should point out that I’m not a gunsmith, so this endeavor is purely about my learning process and what I did to make my short barreled shotgun. Feel free to tell me what you would’ve done differently in the comment section. Also, feel free to share your favorite shops that do this kind of work for a living for anyone that’s interested.

PREPPING THE SOON-TO-BE SBS

Prior to my ATF approval letter, I had not been idle. I located an affordable police issue wood stock and forearm on the equipment exchange forums on AR15.com. I also scoured the internet to find a replacement front sight and the best way to remove the rear sight base. I had also arranged to meet with a local laser engraver to meet the requirements of the NFA.

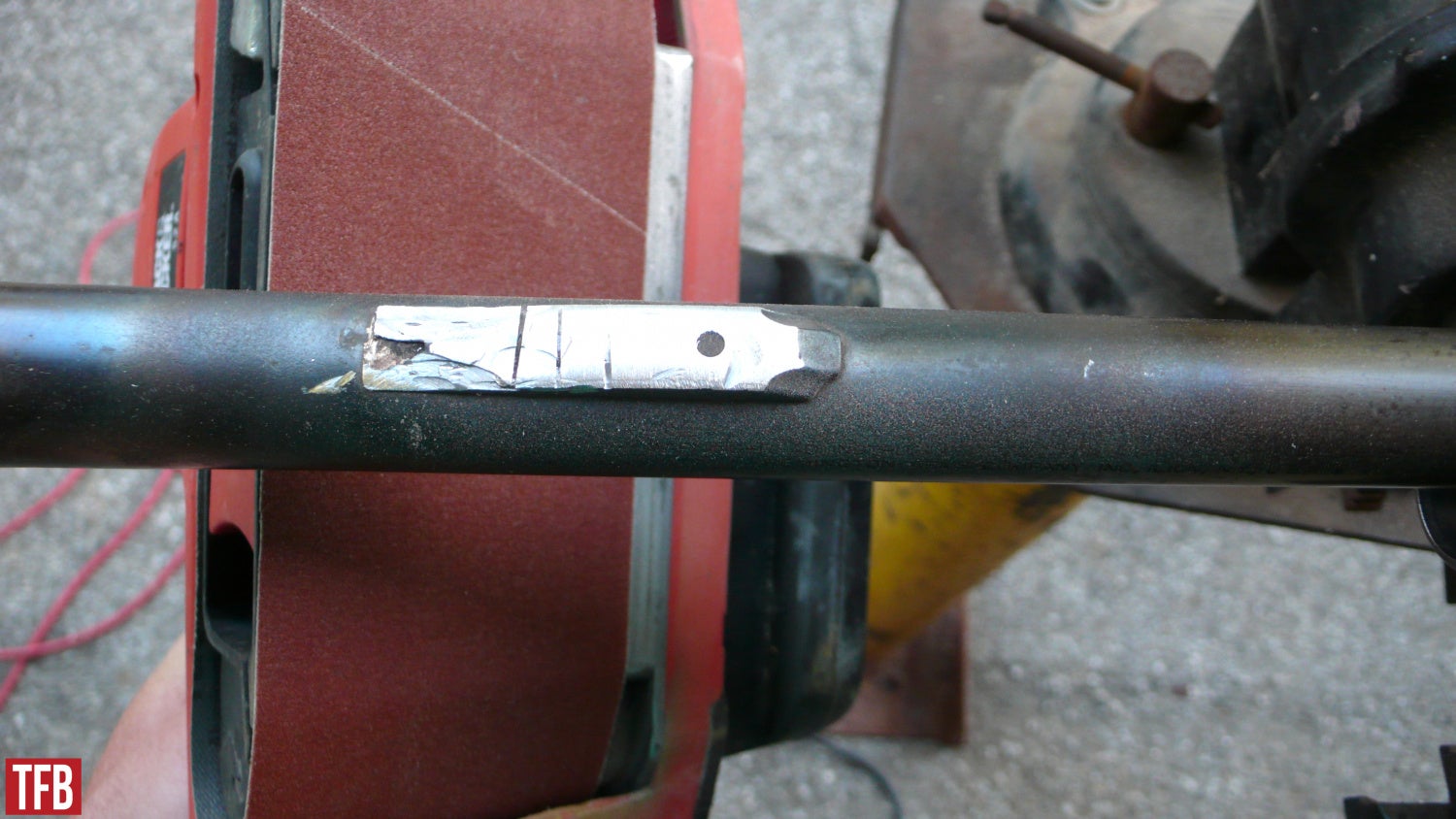

Apparently, trying to heat up the rear sight base with my propane torch wasn’t going to release the solder under the sight base, so I opted to cut most of it off with the Dremel (since my big cutting wheel gave up the ghost), followed up by a file and a belt sander. Just a hair of the rear sight base is still visible on the final product (as you’ll see further down), but it doesn’t draw the eye too much.

Grinding down the rear sight base, half done.

NFA ENGRAVING of my SBS

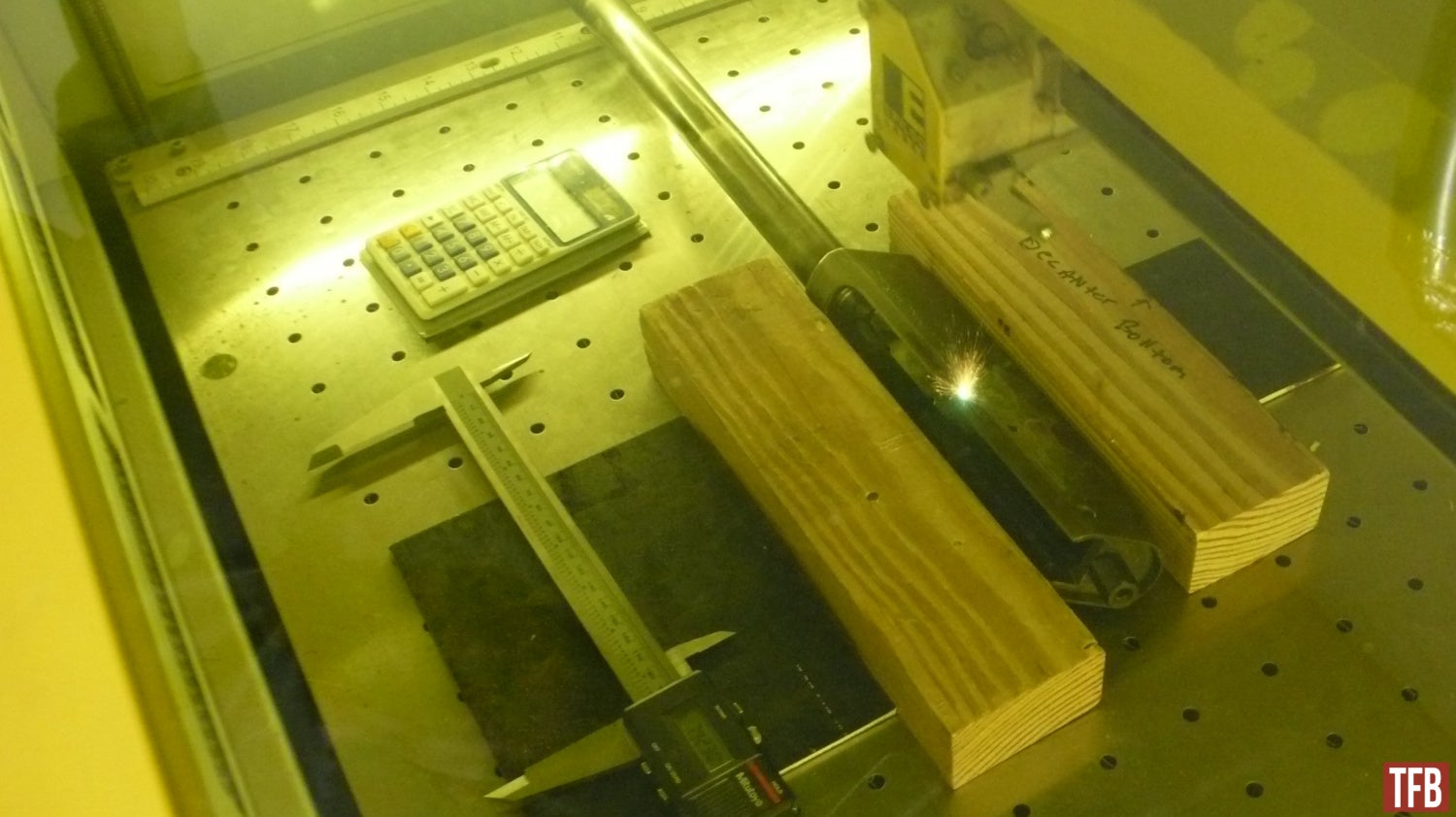

As per the NFA engraving requirements of having my name, town and state engraved on the SBS, I did a Google search for laser engravers. I found one very near me, who specializes in engraving gifts and such, so I called and we set up a time to meet. He didn’t sound opposed to working on a shotgun, but he wasn’t sure how it would go. After some measuring and calculating, he set it up to engrave my information where I wanted it on the bottom left side of the receiver. In this position, my name and location wouldn’t be overly visible once the side saddle was installed, yet if one turns the shotgun upside down, my info would still be readable to enforcers of the law. The engraver charged a very reasonable $20.

MAKING AN SBS, THE CHOP

Once my approval letter was in hand, I set about chopping six inches off of my 18.5-inch barrel. A pipe cutter tool is sometimes mentioned on the internet as being a good method to chopping a shotgun barrel, but on further reading, more experienced gunners suggested that the pipe cutter would actually reduce the bore diameter, which I didn’t want. I decided I’d just use the tried and true hack saw, but I thought I’d score the barrel as a nice guide first with the pipe cutter. However, I found that the barrel was beginning to taper enough that the pipe cutter just spiraled. I then decided to use a triangle file to start a fine groove in which the hack saw could focus on for starting the cut, which worked great.

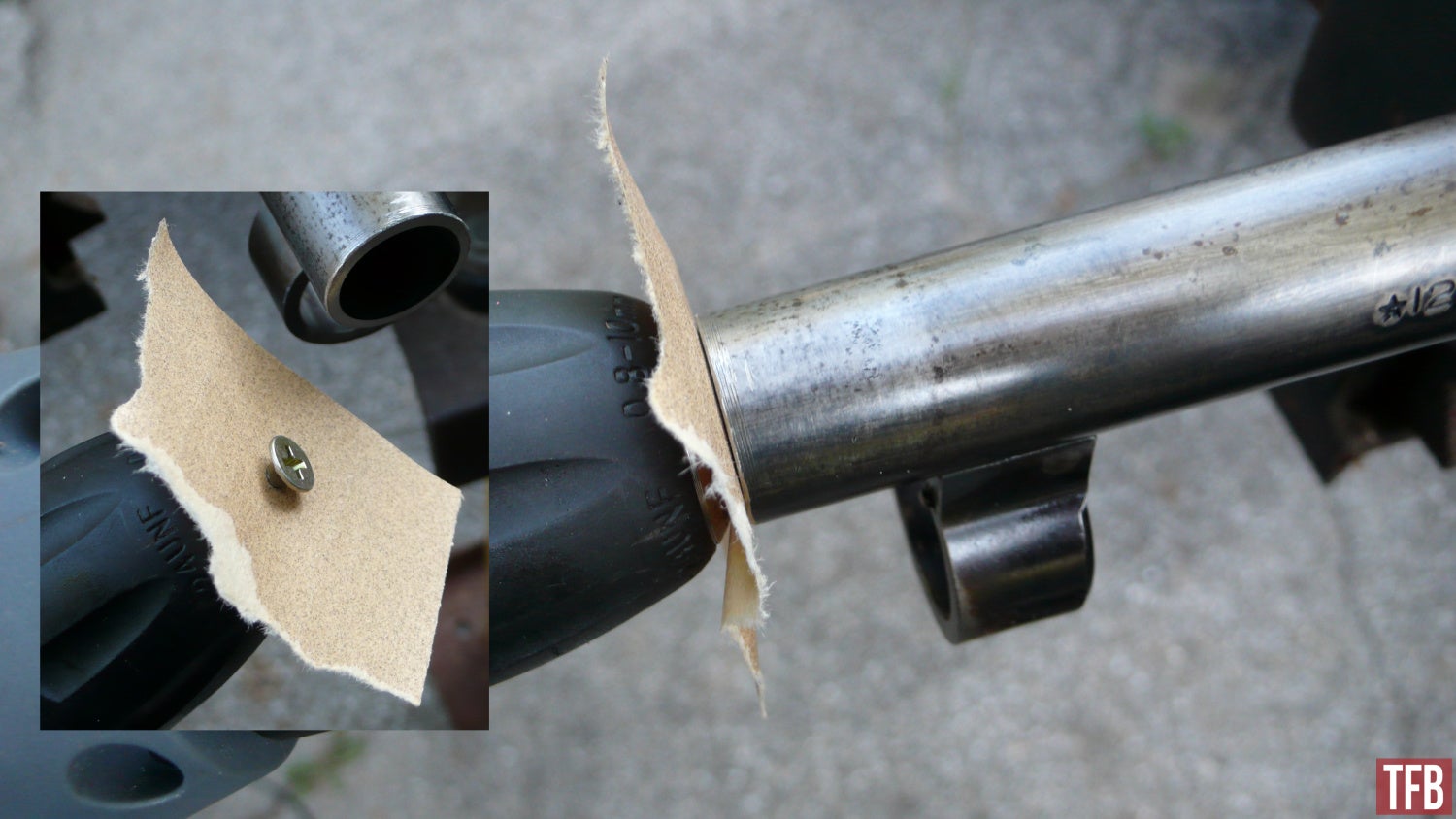

My cut was just slightly off kilter, so I corrected the muzzle’s angle with a bastard file and slightly rounded the outside edge as well. For the sharp inside edge, I took a two-inch square of 180 grit sandpaper and secured it in my electric drill with a screw, then ran the drill against the inside of the muzzle until there were no sharp edges or burrs.

After having chopped the barrel of my shotgun, I picked up the severed six inches of barrel, and I couldn’t help but reflect on the whole issue. I had just done something that society has demonized for generations, yet it felt so insignificant and only reduced 7 ounces from the shotgun. When I picked up my shotgun though, now officially an SBS, I knew this was exactly how a defensive shotgun should be; short, wieldy, and maneuverable.

I had already fitted the new furniture to the 870 before cutting the barrel, but I hadn’t yet refinished the forend to match the beautiful buttstock. I knew I’d have to wait on that task for more free time, but I knew that shortening the buttstock would be quicker, so I did some measuring and used a miter saw to cut an inch off the back end of the stock. I finished off the job with a belt sander on the butt plate to match the new, slender shape of the buttstock. The new overall length was 30.75 inches, with a length of pull at 11.75 inches.

REBLUING MY SBS

The only prior experience of bluing metal was on a couple Cold Steel tomahawks, but I felt that at least prepped me for trying a larger object like my SBS. Stripping the original finish would be new to me though. I read an article about using a vinegar bath and thought I’d give it a go since I already had a few gallons on hand, and it’s very affordable and found in every grocery store, rather than a specialized chemical. The article said that the process should take about two hours, wiping the metal down about every 20 minutes. It worked great and was very close to the estimated two hours. I used a shop paper towel to wipe the old bluing off.

I couldn’t get right to the bluing process that day, so I wiped all the surfaces of the receiver and barrel with gun oil to prevent any rusting until I could get time for bluing. When I was able to get back to the shotgun, I reverted to the directions on the back of the Birchwood Casey Perma Blue bottle I had from my tomahawk project. As directed, I prepped the metal by wiping it thoroughly with denatured alcohol to remove all the oils, which I did with nitrile gloves to prevent oils from my hands interfering with the bluing.

Once the receiver and barrel were dry, I “brightened” the metal with #000 steel wool, then wiped it all down with a dry shop towel to remove the bits of steel wool. I’d read that mildly heating the metal would help it absorb the bluing chemical better, so I gave it a try before applying the bluing liquid.

Once the barrel and receiver warm, I wrapped a paper shop towel on my index finger, wet it with the bluing liquid, then ran it over all the outer surfaces of the shotgun. I let the liquid sit on the metal for about a minute, then I rinsed it with cold water from the faucet and finished up with a dry towel. I repeated the whole process for about five coats before I decided I was happy with it. It certainly wasn’t as dark as it would’ve been from the factory, but I happen to like the “lived in” look. The other perk was that I had pretty much returned it to the same patina as before, but it’s now completely uniform across the whole barrel and receiver.

I used a Q-tip to get the parts that the shop towel couldn’t cover.

The photo doesn’t show the contrast as well as the naked eye, but to get the best photo consistency I had to use a small, windowless room.

After rebluing

INSTALLING SIGHTS ON MY SBS

I planned on keeping my sight picture simple, but from the few times I’d shot slugs through it as an SBS, they were printing higher than I liked, and it seemed as though I’d need more than just a bead. I preferred to go with a dovetail ramp so I could switch the front sight, either to different heights as needed, or for a night sight later down the road. I found the Williams Gun Sight Company, which offer a “Shorty Shotgun” ramp, which has a reduced footprint but still has the classic look to it. They have two options for barrel diameters and different sight heights, of which I went with the .875 diameter and 1/8 inch tall model. The fiber optic insert was also from Williams Gun Sights, but their dovetail cut matches the industry standard at 3/8 inch so it could accept matching inserts from other vendors as well.

I ordered the drill and tap kit from Brownells since the Williams ramp mounts via a single, 6-48 thread pitched screw. I used a center punch to dimple the barrel where I wanted to drill, and the Brownells kit worked great. I used some cutting fluid found at the local hardware store for the process as well. Unfortunately, my first hole was just slightly off-center, so I realigned and did it again. I also plugged the first hole with one of the brass beads from the Brownells kit, then cut it and filed it on both sides of the barrel.

SBS FOREARM REFINISH

Ever since I received my police-style 870 furniture, I didn’t like how the forearm didn’t match the buttstock, so I set to correct that problem, or at the very least, blend them a little better. I also happen to like guns with issue numbers painted on them, but only when stencils are involved. The number “31” sloppily painted by hand (twice) on the forearm had to go. I used the side of a small paint scraper to remove the painted numbers, then lightly sanded the forearm with 180, then 220 grit sandpaper to take the edge off of the reddish hue of the original finish. I didn’t want to work it too hard or deep since I could tell it had some age to it, and I love the contours of this style of 870 forearm.

Once the original finish was reduced to a dull color, I found some “Golden Mahogany” wood stain we had from another project. I used an old sock to apply the stain and started with the top of the forearm since it would be mostly hidden underneath the barrel. The color was slightly darker than the stock, but the color seemed much closer than before.

After 24 hours, I finished the forearm with some Polycrylic to protect the wood from rain and sweat. As I mentioned, I like rack numbers on firearms, so I wanted to add a tastefully painted number on the forearm and stock to give it that police-issued look, so I chose my badge number.

COST

The following costs are rounded up a couple dollars to the nearest five, and reflect some of the second hand purchases I was able to acquire for the build.

- Used Remington 870 Magnum – $200

- NFA Form 1 Tax Stamp – $200

- Replacement Furniture (used) – $50

- Replacement Metal Follower (used) – $5

- Required Engraving – $20

- Front Sight Ramp & Sight Insert – $50

- Side Saddle – $20

TOTAL: $550

This was a fun project, and while it may not meet the standards of the most OCD people out there, I love it and it’s exactly how I think a defensive shotgun should be. Stay tuned for the upcoming review of my Remington 870 SBS to see how she shoots.

What do you think about short-barreled shotguns, and particularly this one? If you’ve done some or all of this type of work yourself, what methods did you use?

Your Privacy Choices

Your Privacy Choices