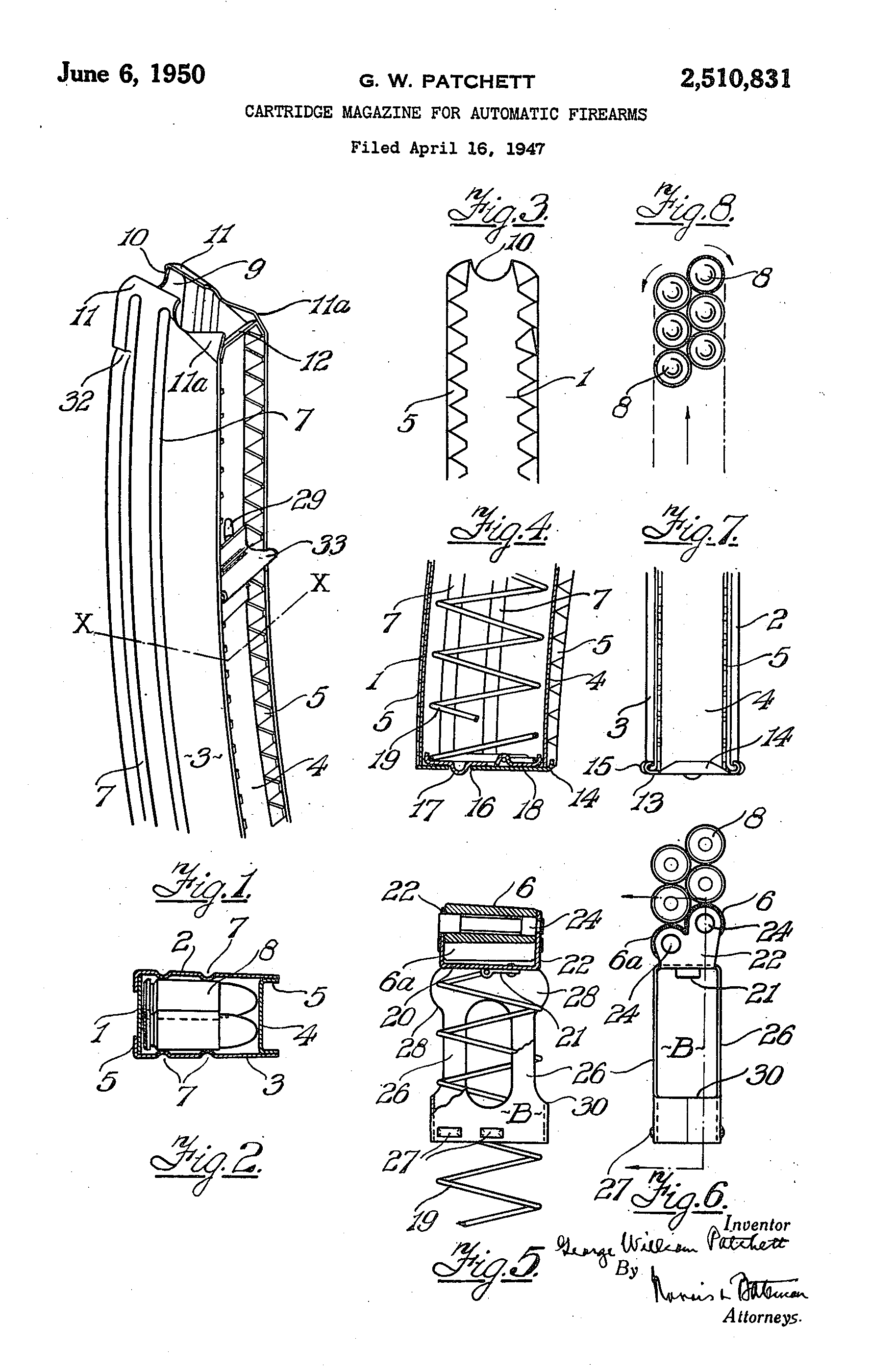

The Sterling submachine gun is often said to have one of the best magazines ever designed. What makes the design so special? Well, it isn’t a STEN magazine for starters. In May 1946, George Patchett patented a new curved magazine which would become one of the Sterling SMG’s most recognisable features. It addressed some of the serious shortcomings of the STEN’s magazine.

George Patchett’s machine carbine, Which later that came to be known as the Sterling, had been initially designed to use the STEN gun’s 32-round double stack, single feed magazine. This makes complete sense, as not only was the STEN’s magazine readily available but it also made sense that the British Army would prefer to retain the large number of magazines it already had in service.

The STEN’s magazine is, however, the gun’s weakest link. It was difficult to load and could feed unreliably when not looked after. The Patchett prototype performed well during initial testing in 1943, but later sand, mud and arctic testing of the Patchett against various other submachine guns highlighted the limitations of the STEN magazine – regardless of the weapon using it.

Check out my video all about the magazine below:

At some point in 1945, Patchett developed a series of new magazines, a 20-round ‘Patrol’ magazine, a 40-round ‘Standard’ magazine and a 60-round ‘Assault’ magazine. But by late 1946, these had been superseded by a 35-round magazine designed to fit into the basic pouch of the British Army’s 1944 Pattern web equipment.

Patchett addressed the STEN magazine’s shortcomings by designing his magazine with a curve which allowed the slightly tapered 9×19mm rounds to feed more reliably. He also replaced the traditional magazine follower with a pair of rollers which minimised friction and allowed dust, grit and dirt to be rolled out of the way improving reliability. Patchett’s magazine was designed so it could be economically stamped from sheet metal and folded and spot welded into shape. It was also simple to disassemble for cleaning and required no tools for disassembly.

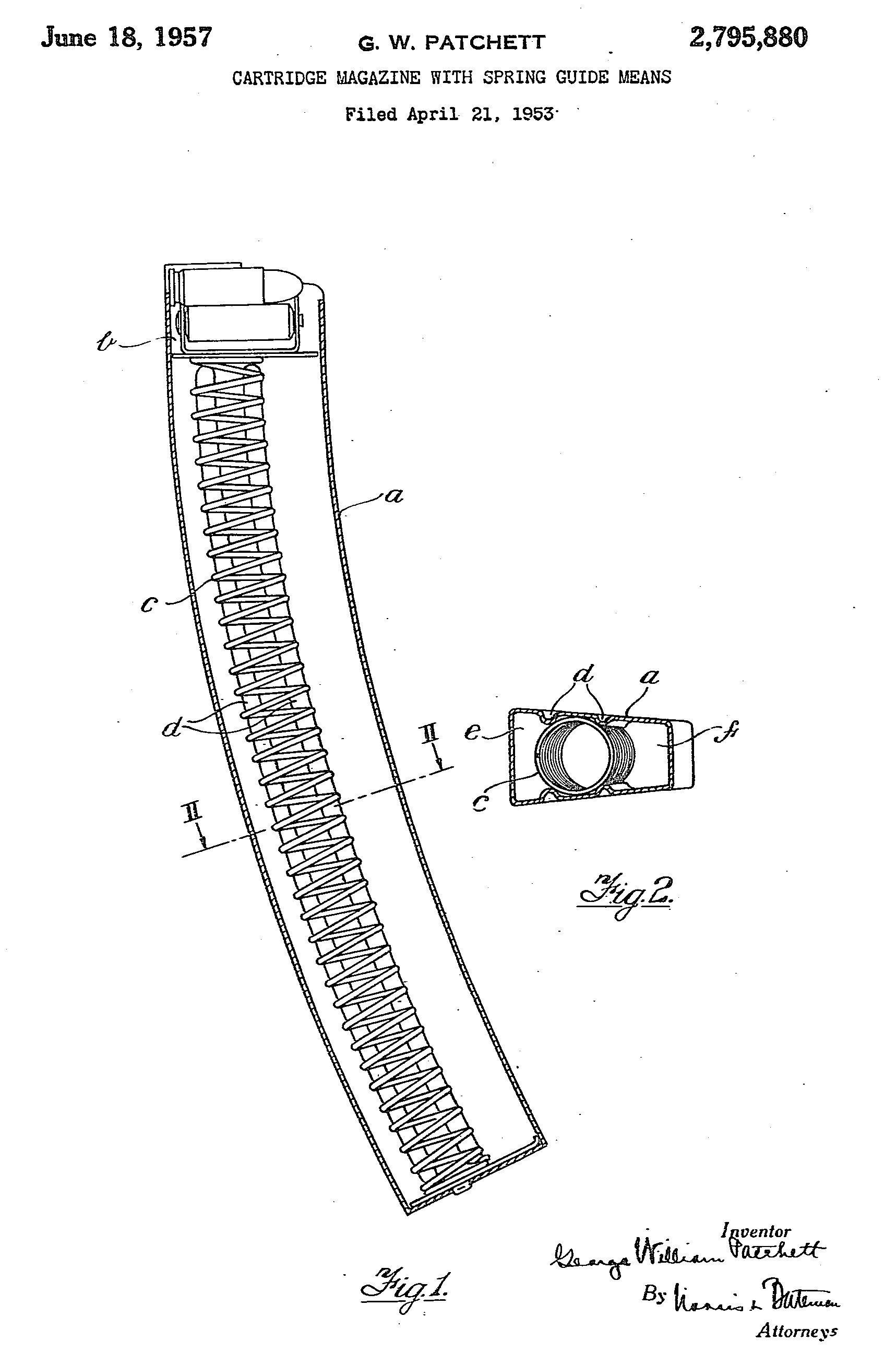

By 1951 the magazine had been largely perfected but a trials report suggested that the magazine’s feed lips needed to be reinforced but despite this the Sterling was said to be “better than all other weapons tested.” Following further development and testing the L2A1 Sterling submachine gun was eventually adopted in the summer of 1954, serving well into the 1990s.

In 1952, Patchett added a pair of strengthening ribs to the inside of the magazine which also further reduced friction on the rollers. He also replaced the oval follower spring with a more efficient circular one with the ribs acting to hold it in place. The final production magazines held 34 rounds and were substantially easier to load than the earlier STEN’s.

The L2A1/MkII, introduced in 1954, was the first version of the weapon to incorporate an angled magazine housing which improved feeding reliability from the Patchett’s patented curved, double stack, double feed magazine. The Sterling’s magazine housing was angled forward slightly at 82-degrees.

The magazines used by the British military differed from Patchett’s design. The British government, perhaps unwilling to purchase the rights to manufacture Patchett’s design, developed the ‘Magazine, L1A2’. Nearly two million of these were built at Mettoy, Rolls Razor, the Royal Ordnance Factory at Fazakerley and the Woolwich Royal Laboratories. The L1A2 magazine was slightly simpler to manufacture but retained Patchett’s roller follower while the magazine’s body was made from two, rather than four, pieces of stamped steel and electrically welded together. The government-designed magazine is 5cm or 2 inches longer than the Sterling factory magazines.

The example magazine seen above and in the accompanying video is Sterling-made and is marked with the company name and patent numbers. We can see the folded sheet metal construction and the overlaps at the rear of the magazine body.

When Canada adopted the C1, a modified version of the Sterling, they dispensed with Patchett’s roller system and designed their own magazine which held 30, rather than 34 rounds, but could be used in all Sterling-pattern guns. This magazine proved to be just as reliable, perhaps suggesting that the key features of George Patchett’s magazine were the curve, double feed and circular spring rather than the rollers.

On the front of the magazine is an over-insertion stop built into the edge of the magazine body, at the rear is another magazine stop with a flat spring which limits rattle and helps properly align the magazine in the breech for optimal feeding.

Your Privacy Choices

Your Privacy Choices