Lots of progress has been made this year in the 3D printed firearms world. We’ve seen the printing world go from just a few parts here and there to having guns that are almost completely made from 3D printed materials. The development group AreWeCoolYet (AWCY) recently reached out to me regarding their Scz0rpion project.

The Scz0rpion (pronounce kind of like szzyrup) is the group’s attempt at a viable 3D printed submachine gun/pistol caliber carbine that aims to use as little factory parts as possible. However, how does the 3D printed gun hold up? We’ll find out today as we dive into the development and testing process AWCY went through to develop the Scz0rpion.

The AWCY 3D Printed Scz0rpion – Is a 3D printed Sub Gun Viable?

Veet, who is one of the developers from AWCY, reached out to me to provide details and answer questions about the recently released print and he has a detailed list of information so that the build can be replicated with little to no officially purchased parts besides raw materials.

Print/Build Details

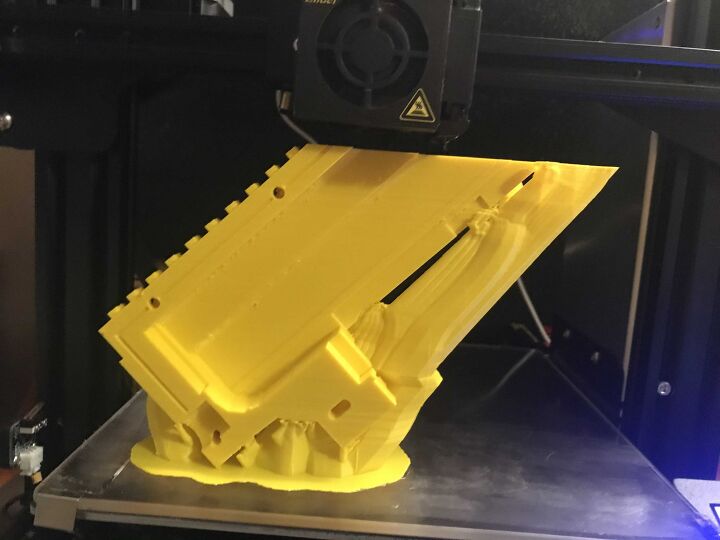

AWCY actually made its first test model through a SOT so that it could be made into a full-auto legally. The purpose of this was to torture test their design to see how much it could handle and to see if it could be a viable print. The full-auto version was printed on a Prusa MK3S which is a fairly affordable $1000 printer. The filament used was NylonX and the total print time was around 48 hours. The long print time is mostly due to the 45-degree print angle that Veet recommends for the build as a 45-degree print angle has noticeably more strength.

Note the 45-degree print angle which is used to make the print stronger. (Veet notes that the print can be done horizontally as well.)

A couple of other test models were able to be printed on an Ender 3 printer in the same configuration using both Overture and eSun PLA, Taulman’s Nylon 910, 645, and Bigrep Pro HT filaments. Generally, the print settings remained the same through each successive print aside from temperature variations. According to Veet, 90% of the prints were printed at a 0.15″ layer hight with a 99% infill. He does tell me however that one model was printed using a 100% infill and a 0.28 layer height and that one worked just fine as well.

Aside from the bolt assembly, trigger pack, ejector and barrel the remainder of the gun is made from common variety pack metric screws and nuts while the receiver and other parts are all 3D printed. Veet and AWCY will provide both a full list of non-3D printed parts that you will need as well as STEP models in the future which will decrease print time, reduce costs and give the printer access to a wider variety of engineering-grade thermoplastics.

What is STEP?

Another one of the developers who is currently working on a machined bolt so that the parts do not need to be ordered from the manufacturer themselves but instead doled out to a local or out of state machine shop. He explains the concept in the quote below:

Someone who understands CNC machining can look at local or out of state machine job shops that are willing to take on the individual components. Some parts, such as the bolt would be easier to be milled on a multiaxis machine, while some of the trigger pack components could be made with a laser/waterjet machine and finished out with post processing and heat treat. Some compents can be made by hand such as the charging handle, which is made from a chopped hex wrench and 3D printed parts.

Torture Testing

One of the biggest problems in the 3D printed firearm world is durability. Compared to glass-reinforced polymers, 3D printing falls pretty short in the strength department. However, that did not stop AWCY from attempting to push the Scz0rpion to its absolute limits. To do this, they created a full-auto version as mentioned above and proceeded to torture test it through 1,000 rounds of relatively sustained fire.

From all the footage I have seen, there only seems to be a few minor hiccups here and there and they tend to look like either light primer strikes or failures to eject. The cyclic rate on the Scz0rpion is absolutely insane and if I had to guess it runs upwards of 900 rpm. The Scz0rpion does not natively have a last round bolt hold open but one can be purchased and integrated into the build from CZCustom – but it is also a $70 part so Veet generally does not install one on his.

The after action pics can be seen below following the torture test. Best I can tell the 3D printed weapon handled that test well and looks like it could handle a couple thousand more rounds with no issues. The build seems to work great!

The printer who is working on the bolt had this to say about the entire process of creating and testing the Scz0rpion from start to finish:

I’ve enjoyed working on this project as it was a unique challenge. I’ve own a 3D printer for a few years now, and have mostly used it to prototype parts before I CNC machined them. Most of the parts are a proof of concept before making them or have been a functional print.

I had to reverse engineer the upper receiver halves and various other parts and make multiple test prints to ensure proper dimensions and fitment for a 3D printed upper. Then brainstorm fastener ideas with other developers to find what work best and what was readily available off the shelf at local hardware stores.

Spreading the Signal

The file for this build will be made available on AreWeCoolYet’s Keybase, their Lbry page, print2A.com repository, and eventually in torrent format for easier distribution, however, the torrent version won’t be available until the bolt for the STEP model is finished. Until then, all of your 3D printers out there can get started on your own builds, and based on all the pictures you’ve seen here, I think you can see that there is quite a bit of variety to be had to make the print truly your own.

Your Privacy Choices

Your Privacy Choices