Vietnamese weapons aren’t particularly mainstream in the Western world, however, we catch a glimpse of them, from time to time. Recently Vlad showed us the latest products of the Z111 Factory, the STV-380 and SVT-215. Now, thanks to the TV channel VTVcab, and its YouTube presence, we can see a few of their details and have a brief tour of the manufacturing facility.

We read about this factory tour from the tweet of Lee Ann Quann, who arguably first offered the English speaking audience the chance to know about the TV reportage:

"Morning with the Z-boys"

Z111 with its workers and products being covered in a TV program. Being one of the prominent armament factories of Vietnam People Army, Z111 is responsible for the production of various firearms. pic.twitter.com/Q20W5ZATNn

— Lee Ann Quann (@AnnQuann) October 6, 2020

Here below we can see the full video. Unfortunately, nobody in the TFB staff speaks the language, nevertheless, the clip is interesting and informative.

While we can hope that a reader speaking Vietnamese will help us in deciphering the spoken content, we can go through a few screenshots.

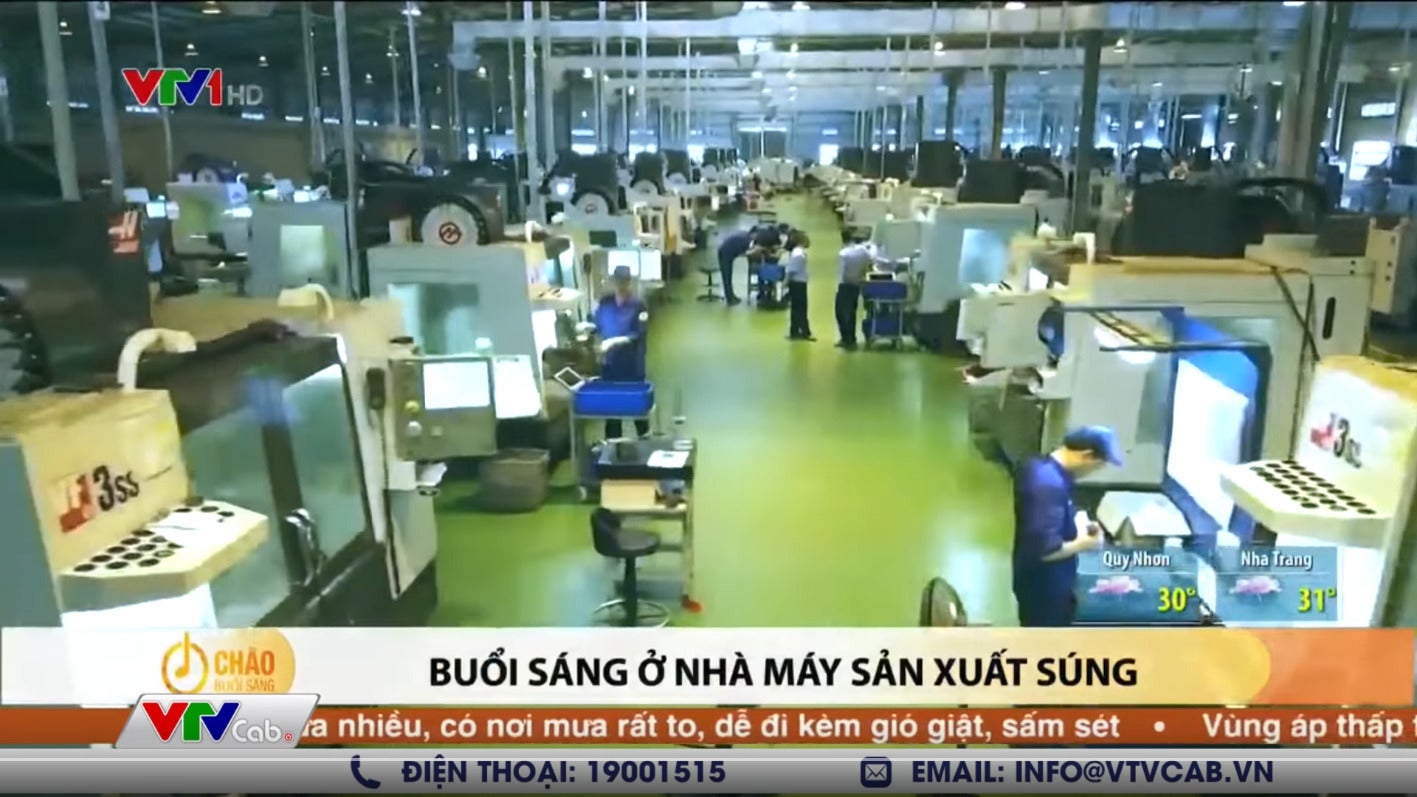

A Look Into Vietnamese Firearms Manufacturing – Machining Centers in Z111 Factory.

A Look Into Vietnamese Firearms Manufacturing – Machining Centers in Z111 Factory.

How many machining centers can you count? While manufacturing of AK based rifles is usually associated with stamping, it seems that the Z111 Factory is fully equipped to handle mass production of CNC milled components.

A Look Into Vietnamese Firearms Manufacturing – Wax patterns; pistol frames on the left – folding stock hinge on the right?

A Look Into Vietnamese Firearms Manufacturing – Hot ceramic molds handling.

A Look Into Vietnamese Firearms Manufacturing – Molten metal pouring into the mold.

The capabilities of the workshop aren’t limited to machining, apparently. Investment casting, also known as lost-wax casting, can be a fascinating process. In the top photo, we see several “trees” made by connecting together patterns molded in wax. These assemblies will be coated with several layers of refractory ceramic slurry; once everything is fully dried, the wax will be burnt off in a furnace to leave cavities ready to be filled by metal. It’s not uncommon to have operators manually placing the preheated ceramic mold in front of the crucible that will pour the molten metal. Once the parts are detached from the casting sprue, they can be finished by machining or manual processes.

A Look Into Vietnamese Firearms Manufacturing – Cast pistol frames.

Above we see a selection of finished cast pistol frames. The final product is likely a licensed copy of the IWI Jericho 941.

A Look Into Vietnamese Firearms Manufacturing – IWI Jericho 941F (Image Credit: IWI)

STV-380 and STV-215

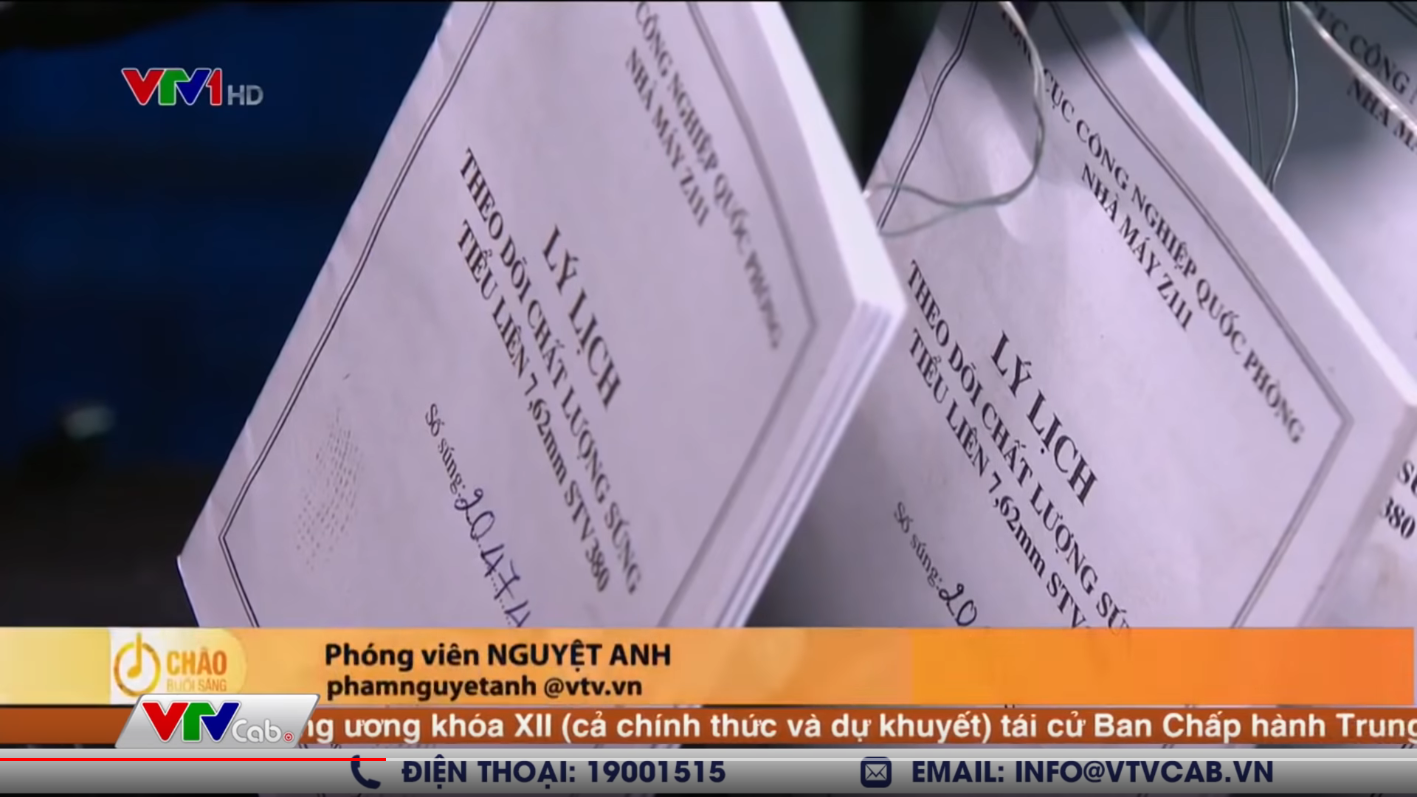

After the brief shop tour with some focus on QC, the clip focuses on the newest product of the factory: the STV-380, a Galil derived 7.62x39mm assault rifle. The journalist handles the firearm and she’s invited to re-assemble it: with some guidance, she appears to do it fairly easily. This sequence allows us to see up close the features differentiating the model from its Israeli counterpart. Specifically the charging handle on the right side and the AK style safety selector.

There are two separate sections of rails on the top side, one on the removable dust cover with rear sight and one above the trunnion area. The bottom of the polymer handguard has a rail for accessories, the sides simply have features to improve grip.

The shorter barrel STV-215 is shown as well on racks.

A Look Into Vietnamese Firearms Manufacturing – STV-380 documents.

A Look Into Vietnamese Firearms Manufacturing – Introducing the STV-380.

A Look Into Vietnamese Firearms Manufacturing – STV-380 handguard and charging handle.

A Look Into Vietnamese Firearms Manufacturing – Re-assembling the bolt carrier group and piston of the STV-380.

A Look Into Vietnamese Firearms Manufacturing – Closed bolt waiting for the installation of the return spring.

A Look Into Vietnamese Firearms Manufacturing – STV-215 in the foreground, STV-380 in the background; the only obvious difference between the models is the barrel length.

Update

We are very thankful to our reader Alex, who kindly provided a very detailed translation of the whole video. You can find it in full here below:

INSIDE THE LARGEST GUN FACTORY IN VIETNAM

News anchor:

We welcome the viewers to Factory Z-111 located in Hoang Trung locality, Hoang Hoa Province. This is one of the top factories producing firearms in Vietnam at large scale. In a year it can produce tens of thousands guns of many types to equip our modern military. Reporter Nguyen Anh will help the viewers investigate.Reporter (spoke quickly with a provincial accent)

Greetings to our viewers! I am honored to be at the largest firearm factory in our country. This factory measures 41.3 hectares (about 102 acres) and has 1000 staff, of whom 700 people engaged directly in manufacturing. (Question directed at workers) Let me ask you what steps are involved in the production of weapons?Military guy: (He described the different processes of making the guns, which is shown in the video. He used very technical words, some of which might be butchered pronunciation of foreign words. I am unable to make out what he’s saying).

Reporter: So what weapons does this factory produce primarily and how many per year?

Military guy: Currently the factory is divided into two zones. One zone is to produce anything from pistols (“short guns” is the literal translation), submachine guns, machine guns, and [bigger guns than machine guns, maybe “automatic cannons”?] . If you are talking about AK (“ah cah”), then about 7000 are produced per year. In this zone… which is a new zone, we manufacture Galil guns [garbled] which is 2000 guns per year. (He actually said “Galil”).

Reporter turning back to audience: When we mentioned AK machine guns, they are familiar guns… but there is a new innovation that is even more advanced! To hear it mentioned made me very curious! In my hands is a new generation weapon that was developed (“researched” was the literal translation) and produced here. (talking to soldier) So from the outside what is different about this gun compared to older generation guns?

Soldier (very thick accent): [garbled] outside there is the picantinny rail (he actually said picatinny!) which allowed it to fit [garbled] 40 mm grenade launchers or red dot sights. This gun has the feature that when looking through the rear sight (“aiming hole” was the literal translation) the soldier can aim very quickly. The stock folds [garbled]. This part of the buttstock is made of rubber which decreases [recoil?] a lot and it’s gentler. This gun is [garbled] 100% in details and very easy to use.

Reporter: Can you show me how to assemble it? [garbled]

Soldier: do this first… [garbled] push on this. (soldier shows the reporter how to assemble the gun) Okay now pull on this handle. (He then handed her the assembled gun).

Reporter: Yes, thank you. After assembly these guns will be test fired prior to being issued (“being used” is the literal translation). Factory Z-111 has two gun ranges, one 100 m and 25 m. The ranges are equipped with safety features as well as features [garbled] allowing for testing.

Video of guy firing gun 3 x.

Reporter: Can you tell me the process of quality control? (literally “process of test firing for quality of manufacturing”)

Military guy: Quality control has two parts. The first part is test firing for function. The second is to test firing for accuracy. The function testing makes sure the gun doesn’t jam… makes sure weapon functions normally… no [hot something?].

Reporter: How many guns do you test per day?

Military guy: We work in groups of 3 people. On average in a day we test function and accuracy of 40 to 100 guns. This depends on the production speed and military unit requirement (he said “realistic unit requirement”… I’m not sure what he meant).

Reporter: Thank you (walking to supervisor). After test firing how do you see the results?

Supervior soldier: After testing the gun at 100 m you can look at this screen here. In this case it determines the gun meets the accuracy standard. When in the hands of soldiers the guns have already been tested [unable to translate].

Reporter: These are the guns that have been test fired and ready to be issued. With capability and responsibility to produce and repair infantry weapons for 60 years, today Z-111 Factory has mastered the manufacturing process… uh Z-111 today received investments in modern techniques from Israel and the manufacturing process is important to national defense and [improve foreign relations, I think?].

All images from VTVcab, via Youtube, unless otherwise specified.

Your Privacy Choices

Your Privacy Choices