Hello and welcome back to The Rimfire Report! This weekly series focuses on the rimfire firearm world and its various ammunitions and sports in addition to the wealth of rimfire firearms out there. This week we’re taking a look at a 3D printed 22LR firearm – The Songbird. The Songbird was created by 3D printers and is made from nearly 100% 3D printed parts but also makes use of some simple office supplies as part of its operation.

The Rimfire Report: The Songbird 3D Printed Pistol with a Nylon Barrel

A big hurdle in the effort to disconnect homemade firearms from the mainstream firearms industry is the need for quality barrels and other items. We’ve seen in more recent times that practices such as electrochemical machining to make rifled barrels with homemade supplies. Although this practice exists, it is still far more complicated and time-consuming than most 3D printers are willing to put into their homemade firearms.

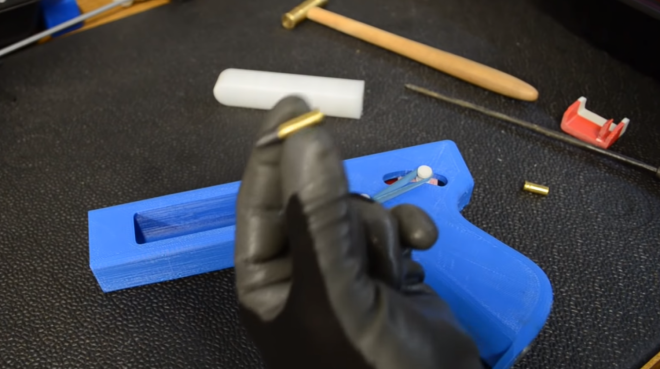

The Songbird takes a unique approach in that this particular design makes use of almost 100% 3D printed parts – including the barrel. The barrel itself is made from Taulman Bridge Nylon. This material takes the strength properties of standard Nylon 645 and combines it with the price points of ABS and PLA plastics. In addition Bridge Nylon also provides a lab certified measure of tensile strength which is something that the 3D printing community was in high demand for.

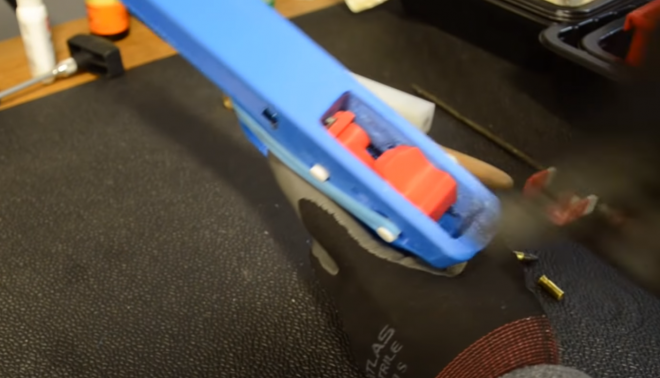

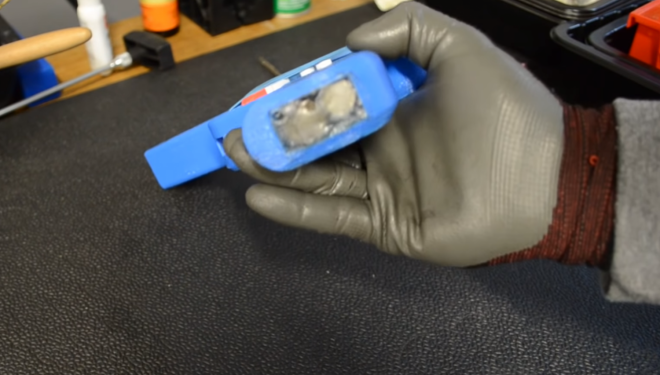

The parts for the Songbird are simple. While the barrel is printed from the Bridge Nylon, the frame as well as the other parts including the trigger pins, trigger assembly, and grip are all made from regular ABS filament. The pistol is printed from the side (as if you were laying the gun on a table) and is one uniform piece. This design necessitates the need to remove several support structures leftover from the printing process.

The remainder of the pieces including the “spring” and firing pin are made from rubber bands and a roofing nail respectively. In order to make the firearm legal within the United States, there is a required certain weight of the metal in the firearm in order to make it legal. See the Undetectable Firearms Act of 1988 for more information on that.

The legally required amount of metal was epoxied into the grip of the pistol.

Durability

Many 3D printed firearms tend to break easily due to the inherent weakness of 3D printed plastics when compared to their more conventional steel and aluminum counterparts. This probably is even more pronounced for pressure bearing parts such as the barrel and chamber. However, using the Bridge Nylon, YouTube user “Guy in a garage” was able to get upwards of 60+ rounds through his nylon printed barrel. For those curious, the infill density of the barrel was pushed to 100% for maximum strength.

In fact, the barrel was so durable, he decided to upgrade the system to handle 357 magnum loads. Initial tests on this design had the structure fail but subsequent tests after repairs allowed him to fire several Federal 357 hollow points through the repaired gun without sustaining any additional cracks.

The 357 Magnum version of the Songbird

Although this is promising, the big negative to the 3D printed nylon barrel is that it does not stabilize the bullets in any way shape, or form despite rifling being incorporated into the print. In a pinch this may not be a problem, however if you’re planning on using the Songbird as a target pistol I’d rethink the 3D printed barrel.

The barrel itself is more or less a smoothbore barrel and thus has no twist to stabilize the bullets. This does make me wonder, however, if projectiles like rifled slugs but miniaturized are on the horizon somewhere as this would eliminate the need for a complicated rifling process.

Field Test/ Accuracy

As stated before, the Songbird features no type of bullet stabilization in the 3D printed barrel. This unfortunately leads to the pistol being very inaccurate even at short distances (in the below video it seems that he’s at a distance of about 5 to 10 yards). “Guy in a garage” did say that the pistol was more accurate when the barrel was freshly printed so perhaps his initial tests had better accuracy results.

The Songbird also does not feature any type of extractor and with the exception of the 357 Magnum version of the gun, it seems like each time the gun was fired and the barrel was removed, you had to use a tool to remove the spent casing before loading another one. Once the barrel was loaded, the hammer would need to be pre-cocked before the loaded barrel was placed back into the gun.

Without changing anything with the design I think a great way to make the setup slightly more practical would be to print several barrels and perform a “New York Reload” in-between shots. This would ensure that a fresh barrel was available and provided more accuracy and would reduce reload times between shots.

Can’t Stop The Signal

I love 3D printing for the simple fact that it is a great way for many minds to produce so many different designs. Each print furthers the technology of firearms in one way or another and further subverts the controls put in place to keep arms out of the hands of free people.

Note the roofing nail firing pin.

I love the concept of a sleeveless barrel and I think it has a lot of potential. If there was a way to introduce some sort of stabilization into the projectiles, it would make the Songbird much more practical. Thoughts and comments always welcome below and thanks again for stopping by to read The Rimfire Report!

All pictures and info for this article were gathered from Guy in a Garage, please go check out his work on other 3D printed firearm projects!

Your Privacy Choices

Your Privacy Choices