Have you been reloading, and want to up your game? Is it time to refine your reloading skill and get more accuracy? TFB has got your back. We teamed up with Lyman to bring you a series on precision reloading.

If you have never reloaded before, stop and check out the Beginners Guide To Reloading. There are important concepts and practices we have explained that will help with higher pressure cartridges.

By no means will this be an expert’s guide on precision reloading. Just one step further to refine the reloading skills you already have. If you have been reloading (I hope you have been), we will take the steps you are already doing and spend some more time refining that skill, allowing you to finish with more uniform cartridges. Each step of the way, we eliminate any cartridges that are not within our specification. We strive to make our cartridge as uniform, to each other, as possible. Uniformity is what gives consistency in your point of impact, and allows you to create that “precise” pew.

Today we will start by discussing inspection and sorting. It will apply whether or not it is a brand-new unprimed or previously shot cartridge. The only thing you will need is your brass and a scale.

A small portable scale that you can carry with you is essential. Especially because in the last step, you weigh each cartridge at the range, and only shoot those that are within your tolerances. Lyman sent me their Pocket Touch Digital Scale. I will be using it throughout our process.

POCKET TOUCH™ DIGITAL SCALE SET by Lyman is a portable scale that easily accompanies you to the range.

SORT AND SEPARATE

“Sort and Separate” is the process of going through and separating the less desirable brass from the brass we want to use. The first step is to separate the brass by the manufacturer. Get some zip locks and put every manufacturer in a separate bag. Different manufacturers will have slight variations in internal dimensions. This can cause slight variations in pressures. That variation will manifest as inconsistencies in point of impact.

Our second step is to choose one manufacturer’s brass, and get a quick weight of the lot, and figure the average. Decide what your specifications are, and remove the brass that is outside of your specifications. I decided on half of one grain. I found my average to be 143.5gn. Any brass greater than .5gn variance from the 143.5gn, are removed. Unfortunately, you will find yourself significantly lowering your amount of desirable brass. To the aggravation of many, this is true even of brand new unfired brass.

Brass on the left is all within my .4 grain tolerance. Brass in the ziplock go back into storage

PRIMER

The consistency even applies to the primer. Inspect the primer hole, see that it is clear of debris and centered. Lyman makes a tool that will uniform the primer pocket. Just insert the tool and give it a turn. For now, I solely rely on visual inspection. In the future, I am sure I will crank up my game.

Primer holes look uniform and are centered. Good to go.

CASE NECK

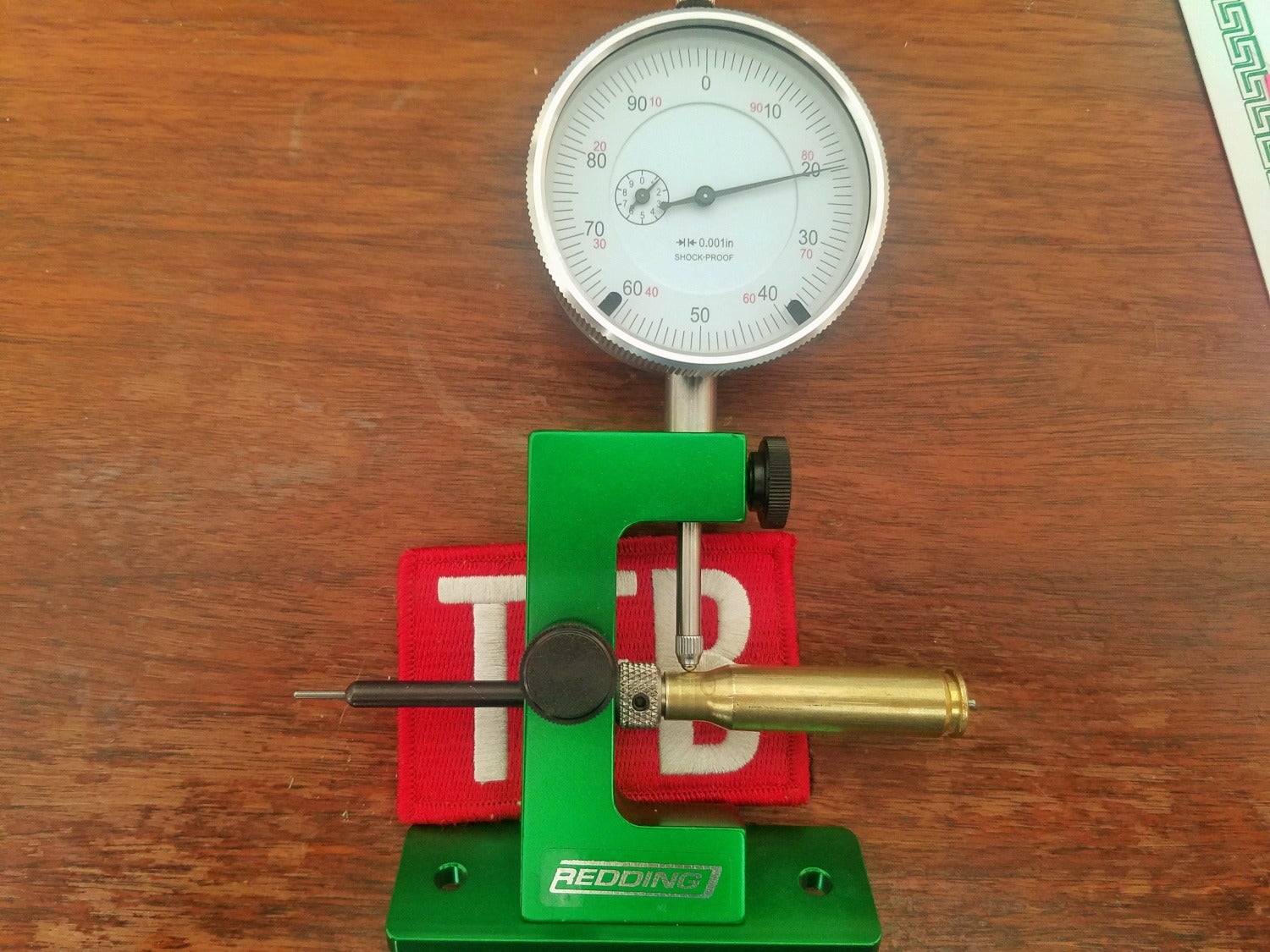

The last thing we should check to gain uniformity is the case neck. If a variation is found in the neck thickness, one can assume that inconsistency will extend down to the rest of the casing. If a casing does not pass a case neck gauge check, then the casing is not used for precision. I have found the majority of brass will pass this measurement.

Measuring the case neck is very easy, and only takes a few seconds

You can purchase the gauge on Amazon.

Conclusion

In my “general” beginner series, I spoke a lot about consistency. The same is true here, it is just more critical. The more uniform the finished cartridges are, the more consistency we will see in point of impact which is why it is “precision reloading”.

If you expect absolute uniformity, you will drive yourself insane. Remember, this is precision reloading for the BEGINNER, so take your time and enjoy making a more Precise Pew.

Next, we will go over powder loads, which is normally the longest step. I have a couple of tips that will help shortcut that process without losing consistency. Until then, put together your toolkit, practice checking, and sorting brass, and don’t forget to go out on the range and reach out and touch something.

You can go to part two, here!

Lyman has had TFB’s back for a while, please support them

Your Privacy Choices

Your Privacy Choices