Last month I was invited out to West Valley City, Utah to visit SilencerCo Headquarters. As an owner of some SilencerCo cans and a fan of their products, I was extremely eager to go check out where my cans were made. Also since I am now behind enemy lines in California, I would get to play with things that I’m not allowed to possess in CA. But that is bordering on politics so let’s move along and check out that silencer magic that SilencerCo seems to possess.

I Got A Golden Ticket To SilencerCo Headquarters

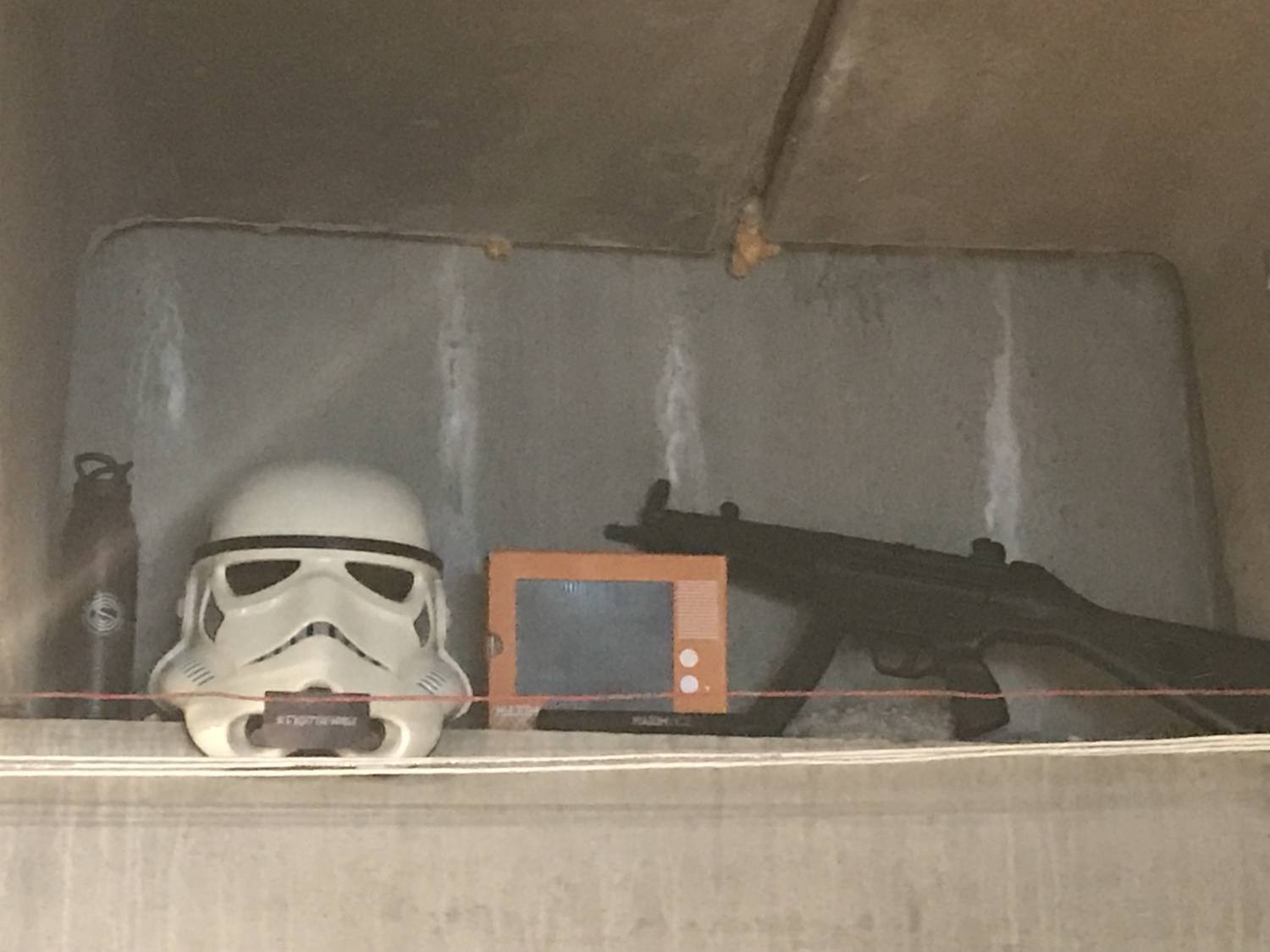

3D printed prototype Maxim9s adorn the office.

This place is full of nerds. I think we will get along great.

The SilencerCo media event started off with a tour of their factory. Having visited GSL Technology a year ago I had an idea of what to expect, at least that is what I thought to myself. SilencerCo is definitely a household name brand in the silencer industry. Some of their suppressors are industry leaders and benchmarks like the Salvo12, Osprey series, Maxim9 and the Omega 9K are just some of the best-known cans they make. Although the Maxim9 is in a league of its own.

The tour started off similar to other factories I have visited. An impressive display of their raw materials. There are long bars 12-20ft. 316-320 steel for their baffle spacers. Titanium for some of their suppressor tubes as well as Inconel and Stellite for blast chambers.

Due to the number of media representatives, there were around 20 of us there, we were broken up into two groups. My groups’ tour guide was Director of Product Management, Gianni Donati. You may know him from his work at Triple Aught Design. He and his wife left TAD Gear to work at SilencerCo.

Gianni shows an exposed Hybrid suppressor.

What set the SilencerCo headquarters apart from companies like GSL Tech is the sheer volume of turning machines. Just several years ago SilencerCo only had 6 machines. Now they have 54 turning machines. That includes the numerous CNC mills and CNC lathes.

A Sparrow hot off the mill.

SilencerCo Headquarters used to be a bread factory. One of the walls is adorned with a hand-painted mural depicting their Fight The Noise campaign.

All throughout the factory are these LCD screens with current live info on the productivity of each machine. Gianni and many of the other employees can access this information live on their phones or computers to see the current status of the company’s productivity down to the second. They can track how long a machine is down and address those issues as quickly as possible.

This is a Tombstone Mill aka horizontal mill. This avoids what is called “double ship cuts”. A traditional mill cuts downwards and due to gravity the chips that fly off will sometimes not fly far enough and get in the way of the tool causing the tool to have to move or cut that chip. This adds unnecessary wear to the tools. So by having the parts mounted on this giant tombstone the chips will fall away and not get in the way of the tool.

Osprey suppressor tubes freshly milled.

Osprey parts fresh from the mill.

SilencerCo uses this wire EDM machine to cut the final bore diameter after a can is welded together. This is necessary due to tolerance stacking. SilencerCo holds tight tolerance as much as possible when machining components of their suppressors. But when you stack multiple parts together that tolerance difference gets bigger and bigger.

Concentricity is crucial so you don’t have a baffle strike so the wired EDM takes out any high spots in the baffles.

Any suppressor that is welded like the SpecWar, Hybrid, Chimera, and Omega goes through mount thread cutting and is done concentric to the baffles. Then they flip the can and thread the front for the end cap.

With regards to finishing the suppressors, they brought in Cerakote, Bead Blast, Anodizing and Black Oxide in house. They used to outsource anodizing and black oxide but due to quality control issues and consistency, they brought those operations into SilencerCo Headquarters.

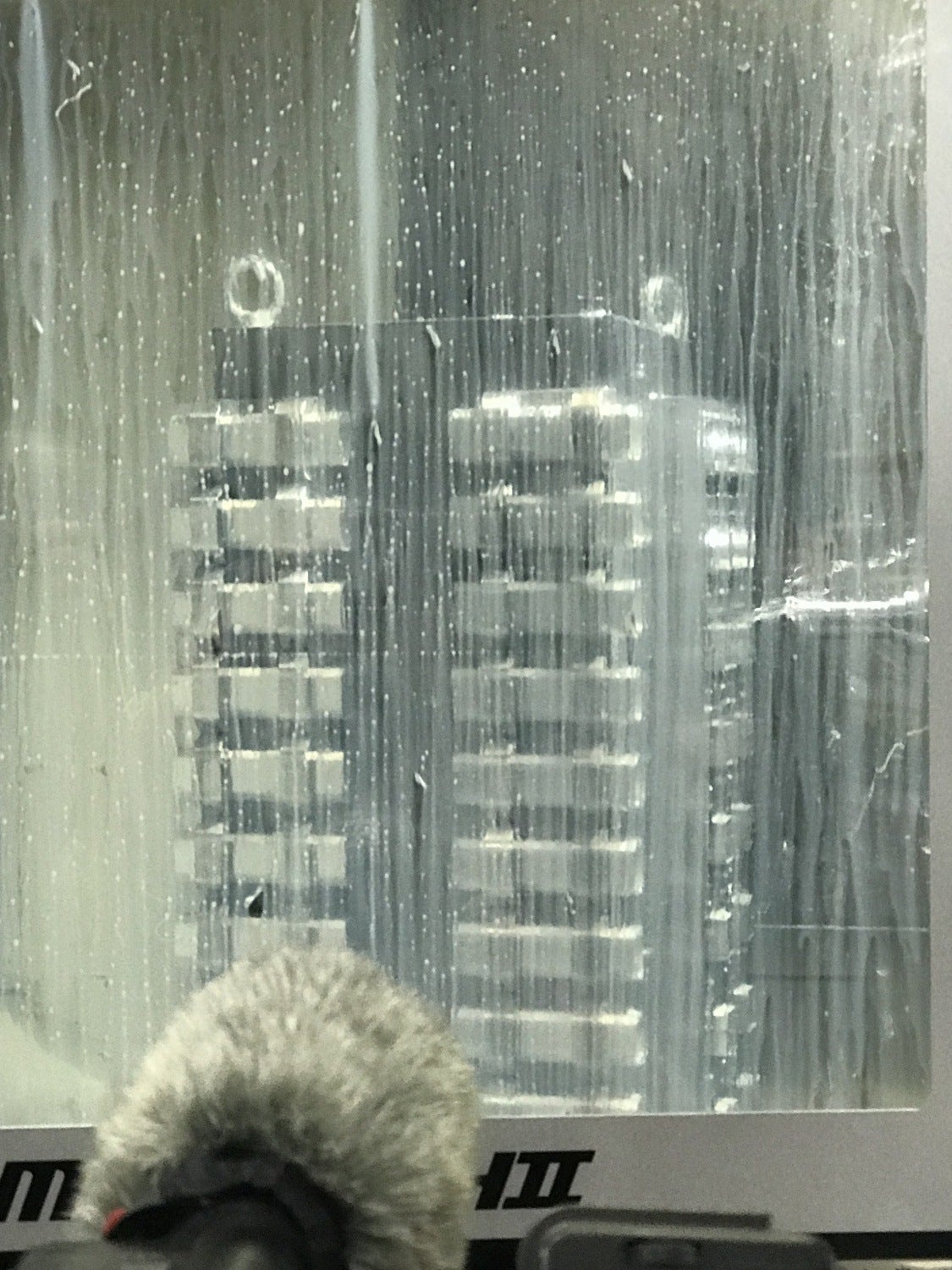

Like any reputable manufacturer, they have a quality control department. This machine has programmed designs of all the parts it tests and measures critical surfaces to see if they are in spec. 1 out of every 2-3 parts are measured. But in the case of any new product or a critical component that requires high tolerance like a piston then every part is checked by the QC department.

This machine uses two camera lenses to create a perfectly flat image. For those who have played with cameras and product photography, you will notice that a single lens will often distort the perspective of an object. Here that is eliminated with binocular camera lenses.

A faster and easier system is this one that uses light to cast a shadow and they can measure off the shadow.

In the lunchroom, the owner of SilencerCo had a custom chess set made using an assortment of suppressor parts. I wish they could offer this as an actual product but sadly the ATF believes all suppressor components must be regulated.

SilencerCo At The Range

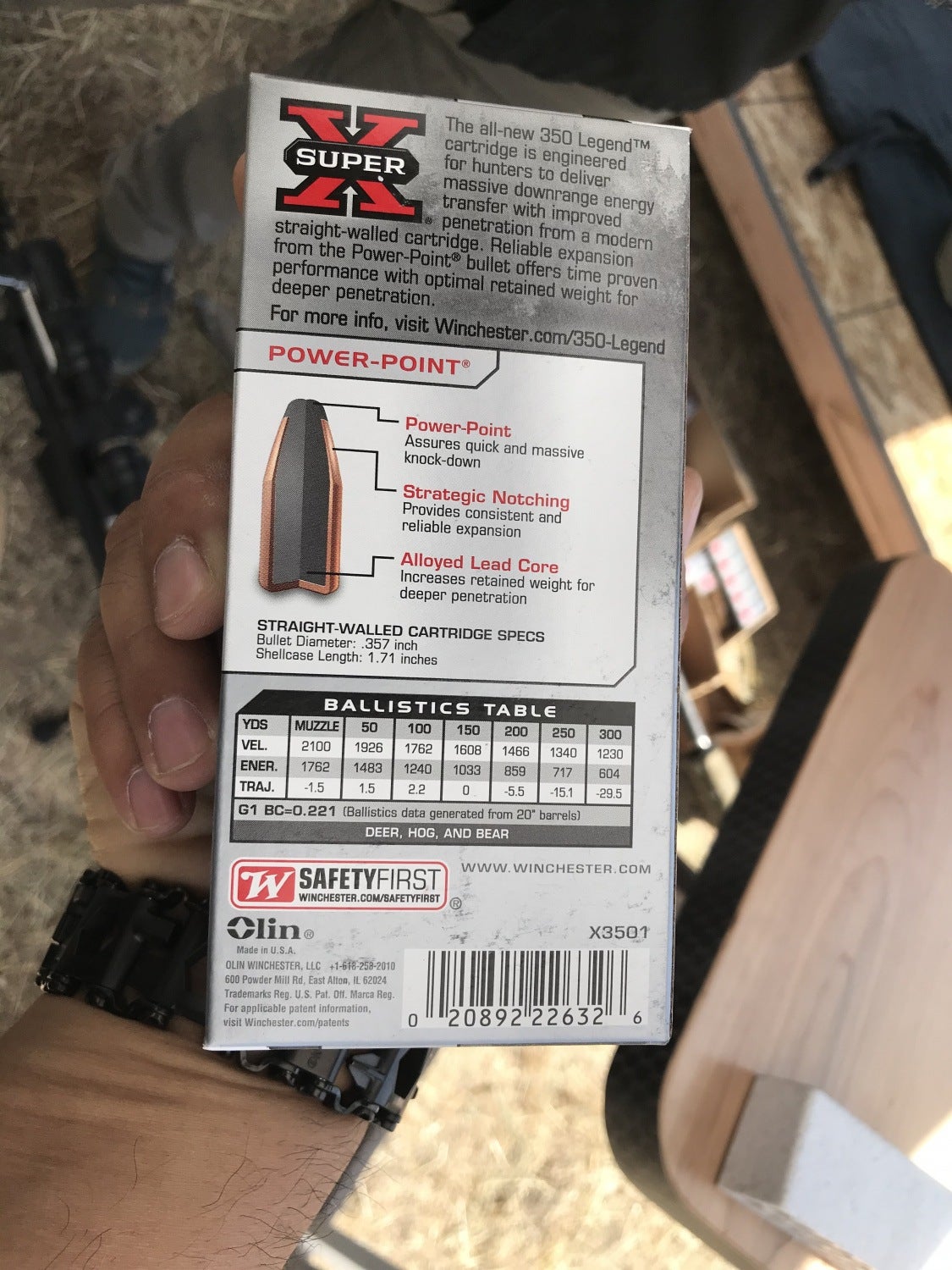

After the factory tour and lunch, we hit the range. SilencerCo setup two shooting sections. The first one was for rimfire and pistol caliber suppressors. Further down the line was for centerfire suppressors. They unveiled a new suppressor that unfortunately I cannot discuss details until the embargo is removed but I can say it is true silencer magic. One interesting facet of this range session was that Winchester Ammunition was there providing most of the ammo we were using. The Winchester representative brought along their new 350 Legend ammo and a Ruger American chambered in 350 Legend.

The new can that is coming out was mounted to the Ruger American so I cannot show it to you, sorry. I can tell you it was surprisingly quiet. But here is the ammo!

350 Legend on the Left and .30-30 on the right.

The Ruger American uses AR-style magazines but they are 350 Legend specific. Normal PMAGs wont feed 350 Legend properly.

SilencerCo had set up steel targets and I hit a coyote shaped target at around 200 yards away. SilencerCo also had their long rage gurus out to help us with hitting steel at 1,000 yards. One of the employees is an extreme long-range fanatic. He has shot a target 5,114 yards away, nearly 3 miles away!! So hitting 1,000 yards is just where he confirms zero and warms up.

I shot the Barret MRAD in .338 Lapua. Listen to how quiet the gun is in the video below. That was my hit on 1,000-yard steel filmed by one of the SilencerCo long-range employees.

At the rimfire/pistol section, we got to shot the gamut of their suppressors. The Switchback is a .22LR rimfire can that even I didn’t know they made. It was released last December but hasn’t gotten the attention it deserves. It is a modular can that can be used in short, medium or full-length configurations.

On a 16″ bolt action .22LR rifle, the short configuration works very well.

And while I cannot mention specifics here is the embargoed wonder can on their post sample HK MP5. (I got approval to post this video from their Director of Marketing).

Earlier I posted about their Non-NFA Maxim9.

I would like to thank Jessica, Gianni and the rest at SilencerCo Headquarters for hosting us. It was truly reinvigorating to exercise my second amendment rights quietly and discover what makes SilencerCo so great. Unfortunately moving out of California is not in the cards for me and my family but I can see the allure of West Valley City, Utah.

SilencerCo is staffed with die-hard outdoor enthusiasts. Many of them, Gianni included, are avid hunters. They are passionate about what they do and it shows in the work they do. In just a span of a few years, SilencerCo went from six CNC machines to 54! They clearly have that suppressor black magic that keeps customers wanting their products. Marketing can only get you so far. But having dedicated people making quality products that perform extremely well will get people interested in your products and SilencerCo has it in spades.

We are committed to finding, researching, and recommending the best products. We earn commissions from purchases you make using the retail links in our product reviews. Learn more about how this works.

Your Privacy Choices

Your Privacy Choices